Objective: To prevent belt tracking issues before the critical curved areas of the belt,

causing belt damage.

Challenge: The challenge was to track a horizontally curved, overland primary

crusher belt before it gets to a critical mis-tracking stage and eventually damages

the belting system. This would be an exceptionally difficult challenge due to the

harsh environmental conditions of the operation. They had been using conventional

guide roller trackers which continually failed, causing belt damage.

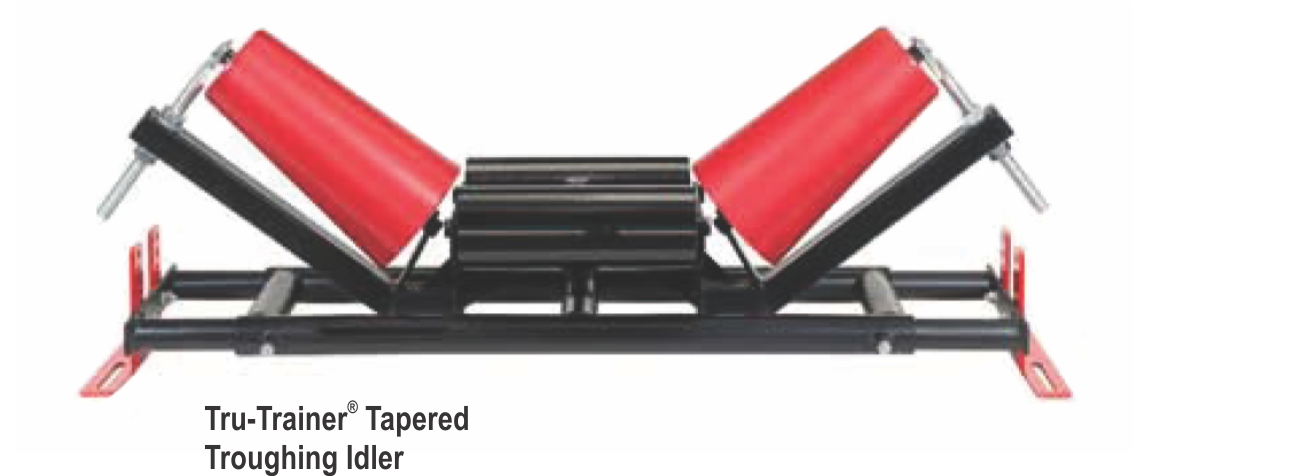

Solution: ASGCO® recommended a series of Tru-Trainer® Tapered Troughing Idlers

be installed before the curved section of the belt. This would center the belt before those

critical areas, avoiding the possible loss of material due to belt mis-tracking on these

high speed and high tonnage loads on the overland crusher belts.

Results: This new generation of Tru-Trainer® Tapered Troughing Idlers is very easy

to install thanks to its’ unique design concept. As the taper wing rollers are inline, it

operates on both on Uni-directional or Bi-directional conveyor belts. The tracking is

done by the tapered wing rollers which are lagged and can be easily adjusted between

25°- 55°. The tapered wing rollers ensure that the idler activates immediately as the belt

moves off center. ASGCO®’s Tru-Trainer® Tapered Troughing Idler’s superior belt tracking

performance is saving the mine money due to less spillage, less downtime and less belt

wear. The customer was ecstatic with the number of units correctly installed in the minimal

allowable time for their maintenance window.

- Exceptional Performance – The combination of the tapers

and unique center pivot, provide fast, reactive and

continual tracking in all conditions - Individual rollers for easy replacement – Both the taper

and center roller can be individually replaced as wear occurs. - Enhanced Center Pivot – The unique heavy duty pivot

design provides instant activation to centralize the belt

to keep it running center. - Maintenance Free – Bearings do not require any greasing