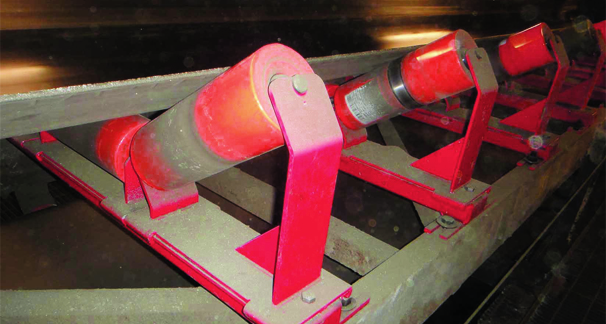

This underground rail car transfer point for Sub-Bituminous Coal was…

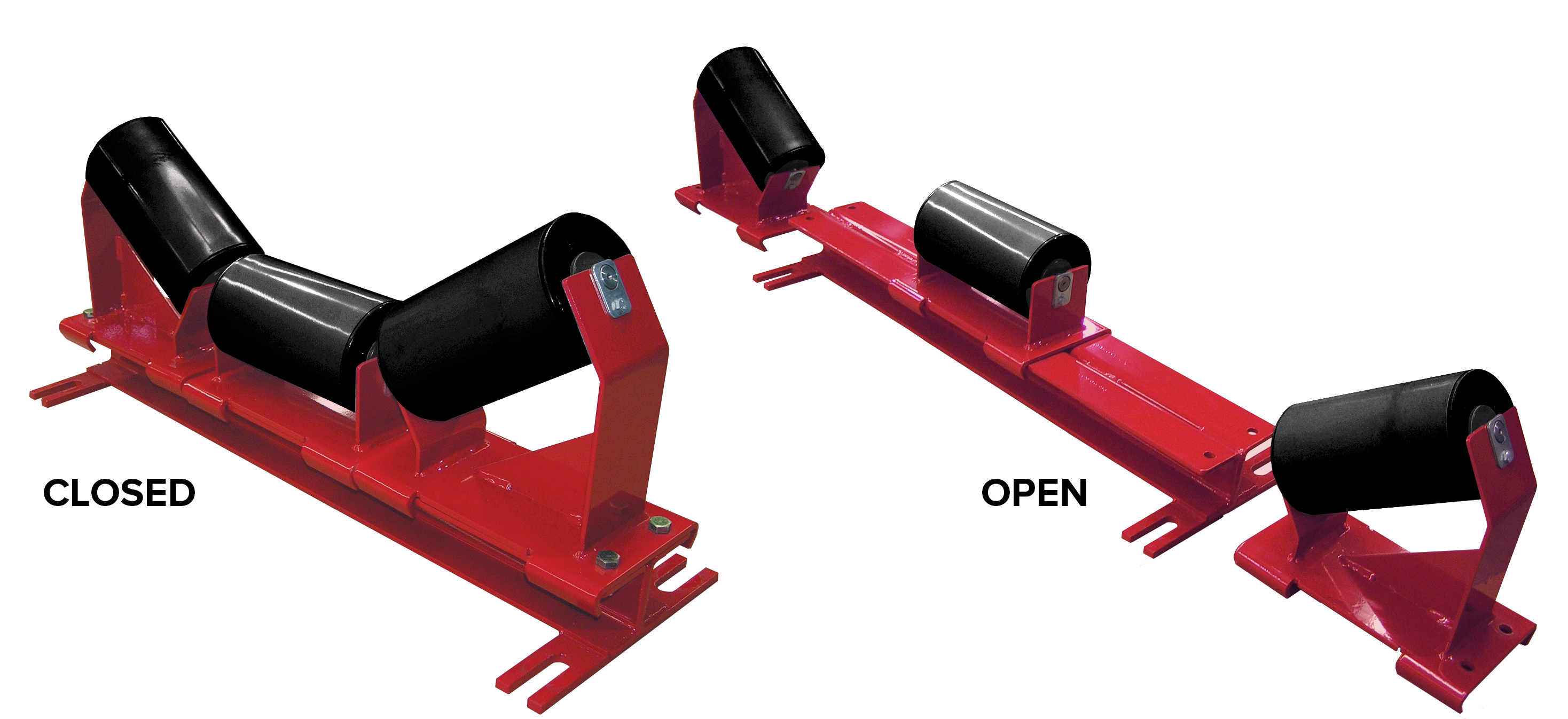

Read More >CHANGE ROLLS WITHOUT REMOVING ADJACENT IDLERS

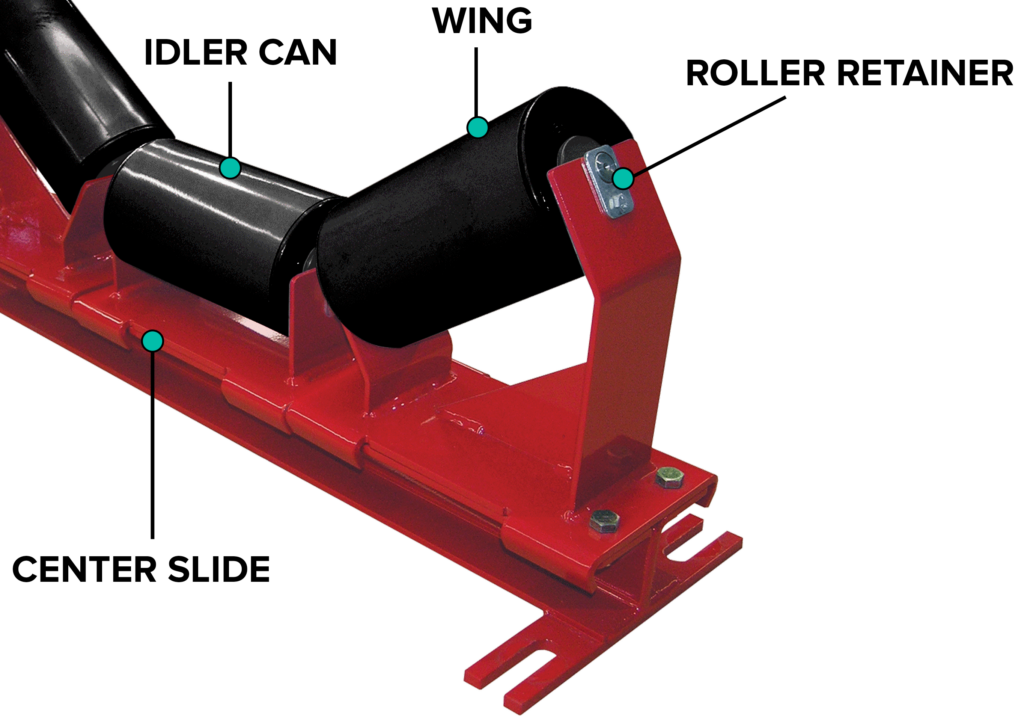

Design Features

- Perfect for Confined Spaces – due to the frames only take-up 8” (200mm) of width when using 6” (150mm) rollers.

- Improves Safety – and maintenance by allowing rollers to be easily removed without having to remove any of the belt idler frames.

- Meets all CEMA Standards – and available in any belt width, troughing angle or idler.

- Idler Rolls – we can provide CEMA C, D or E steel or impact rolls.

- Slide-Ler™ (One-Sided) – Also available.

Product Specifications

Troughing – 20°, 35° or 45° Application – Aggregate, Cement, Mineral (Phosphate, Potash, Salt) Mining, Underground Mining, Coal Fired Power Plant, Steel Mill, Iron Ore, Bulk Shipping TerminalsPart Numbers

One Sided Slide-Ler™

Troughing Idlers available in 20,35 or 45. *XX =Degree of Trough

Designed to be maintained from one side of the conveyor system.

| Part Number | Belt Width in. | Belt Width mm. | Weight lbs |

|---|---|---|---|

| M-ASG-OS-SLIDELER-18-(XX) | 18 | 450 | |

| M-ASG-OS-SLIDELER-24-(XX) | 24 | 600 | |

| M-ASG-OS-SLIDELER-30-(XX) | 30 | 750 | 65 |

| M-ASG-OS-SLIDELER-36-(XX) | 36 | 900 | 73 |

| M-ASG-OS-SLIDELER-42-(XX) | 42 | 1050 | 81 |

| M-ASG-OS-SLIDELER-48-(XX) | 48 | 1200 | |

| M-ASG-OS-SLIDELER-60-(XX) | 60 | 1500 | 135 |

| M-ASG-OS-SLIDELER-54-(XX) | 54 | 1350 | 137 |

| M-ASG-OS-SLIDELER-72-(XX) | 72 | 1800 | |

| M-ASG-OS-SLIDELER-84-(XX) | 84 | 2100 | |

| M-ASG-OS-SLIDELER-96-(XX) | 96 | 2400 |

Part Numbers

Slide-Ler™ Modular Idler Frame

Troughing Idlers available in 20,35 or 45. *XX =Degree of Trough

* Note: Idler rolls to be supplied by customer

| Part Number | Belt Width in. | Belt Width mm. | Weight lbs |

|---|---|---|---|

| M-ASG-SLIDELER-18-(XX) | 18 | 450 | 52 |

| M-ASG-SLIDELER-24-(XX) | 24 | 600 | 63 |

| M-ASG-SLIDELER-30-(XX) | 30 | 750 | 70 |

| M-ASG-SLIDELER-36-(XX) | 36 | 900 | 86 |

| M-ASG-SLIDELER-42-(XX) | 42 | 1050 | 99 |

| M-ASG-SLIDELER-48-(XX) | 48 | 1200 | 112 |

| M-ASG-SLIDELER-54-(XX) | 54 | 1350 | 120 |

| M-ASG-SLIDELER-60-(XX) | 60 | 1500 | 126 |

| M-ASG-SLIDELER-72-(XX) | 72 | 1800 | 161 |

| M-ASG-SLIDELER-84-(XX) | 84 | 2100 | - |

| M-ASG-SLIDELER-96-(XX) | 96 | 2400 | - |

Solutions Case Studies

Challenge: The challenge was to be able to remove and to…

Read More >