Challenge: For many years this conveyor had a hydraulic three…

Read More >Accommodates Excessive Force On Conveyor Belts & Heavy Loads

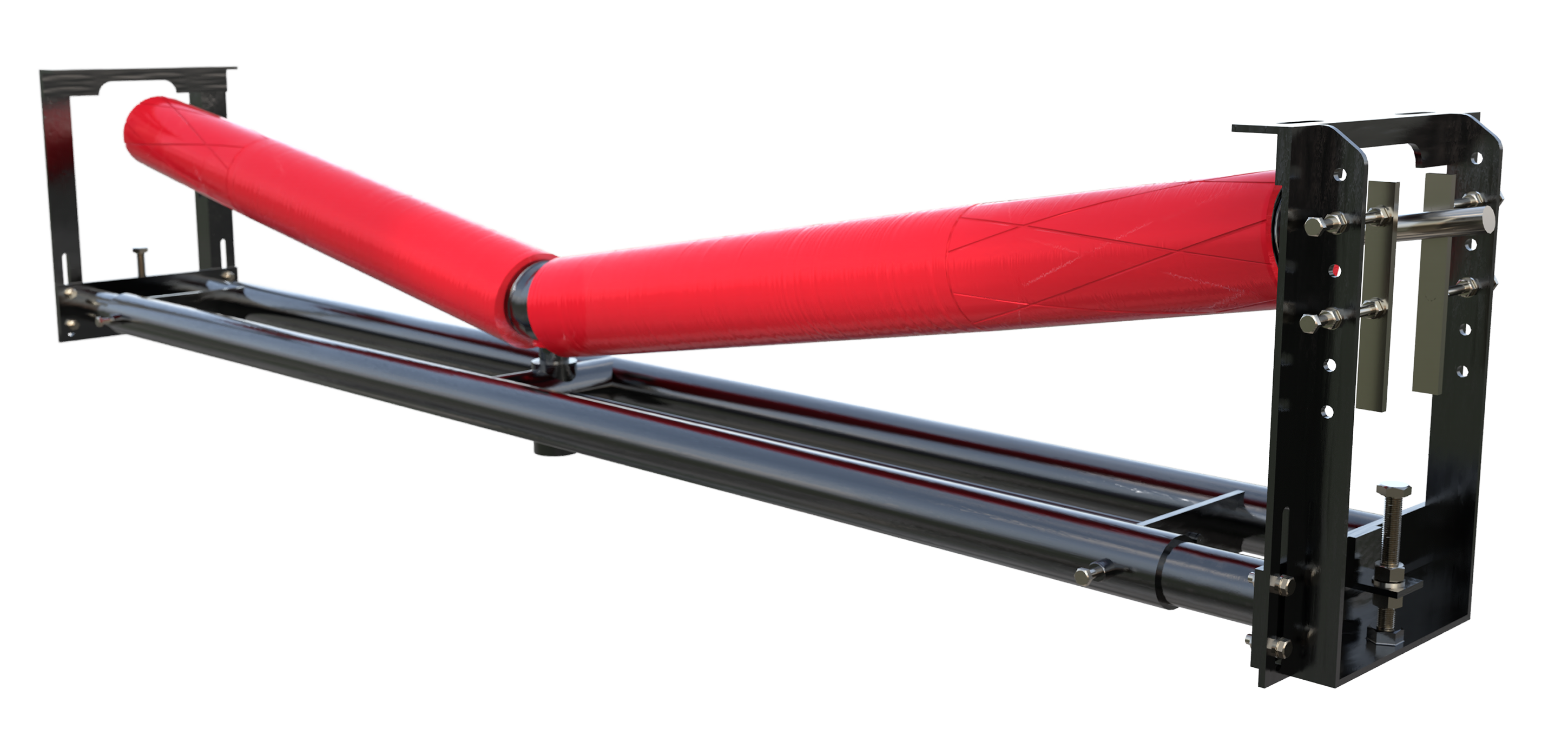

Design Features

- Two Separate Tapered Rolls – are mounted into the pivot mechanism and can be individually replaced as wear occurs.

- Designed for High Speed/PIW Conveyors – to operate and last in severe conditions, wet and dry, and aggressive mining conditions. Conveyor belt speeds that exceed 800 fpm and/or greater than 1500 PIW.

- Accommodates Excessive Force – encountered with wide belts and heavy loads.

- Enhanced Sealing/Bearing System – needle thrust and tapered roller bearings and enhanced sealing system for the most aggressive mining conditions.

- Individual Rollers for Easy Replacement – separate tapered rolls are mounted onto the pivot mechanism, which can be individually replaced as wear occurs.

PRODUCT SPECIFICATIONS

Application – Aggregate, Cement, Mineral (Phosphate, Potash, Salt) Mining, Coal Fired Power Plant, Hard Rock Mining, Metals (Copper/Gold) Mining, Steel Mill, Iron OrePart Numbers

Tru-Trainer® Dual Return

| Part Number | Belt Width in. | Belt Width mm. | Weight lbs |

|---|---|---|---|

| ASG-TTDR-120-1 | 48 | 1200 | 295 |

| ASG-TTDR-135-1 | 54 | 1350 | 304 |

| ASG-TTDR-150-1 | 60 | 1500 | 335 |

| ASG-TTDR-165-1 | 66 | 1650 | 351 |

| ASG-TTDR-180-1 | 72 | 1800 | 368 |

| ASG-TTDR-210-1 | 84 | 2100 | 437 |

Literature Downloads

Solutions Case Studies