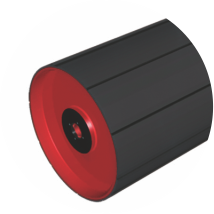

Corrects Belt Slippage And Premature Wear

Design Features

- MSHA approved for mine use – meets all requirements for flame resistant solid products taken into mines. Acceptance Marking No. MSHA IC -174/2

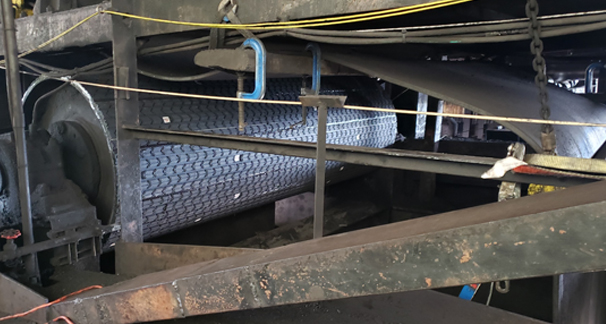

- Increase Productivity – by delivering increased traction between the conveyor belt and pulley, and increasing pulley life and reducing buildup.

- Improved Conveyor Belt Tracking – due to the Arrowhead patterns self-cleaning ability, which reduces material carry-back build up and thereby eliminates the major source of misalignment.

- Superior Wear – ability in abrasive or highly wet or dry applications as seen in below ground and above ground mining.

- Bonding Strength – that is superior to others, due to 3mm of our neoprene compound vulcanized into bottom-side of the lagging.

- Easy Installation – can be done in place, on plant site, at your local distributor or at the pulley manufacturer. Each roll is ½” or ¾” thick x 10” wide by 21.3’ long. 300’ (90m) long rolls will be available in January of 2006.

- Available – in Drive and Non-Drive Rubber Pulley Lagging and Natural and MSHA Grade

PRODUCT SPECIFICATIONS

Thickness – 5/8” and 1” Width – 10” (400 mm) Length – 21.3’ Rolls – 300’ (90m)Part Numbers

Arrowhead™ Rubber Pulley Lagging

| Part Number | Style | Durometer | Thickness | Width | Weight lbs |

|---|---|---|---|---|---|

| ASG-10X21.33-1/2-TRL | Drive | 60 | 1/2" | 10 | 42 |

| ASG-10X21.33-3/4-TRL | Drive | 60 | 3/4" | 10 | 60 |

| ASG-10X21.33-1/2-TRL-PLN | Smooth | 60 | 1/2" | 10 | 48 |

| ASG-10X21.33-1/2-TRL-SM | Smooth | 45 | 1/2" | 10 | 52 |

| ASG-10X278-1/2-TRL | Drive | 60 | 1/2" | 10 | 626 |

Part Numbers

Arrowhead™ MSHA Rubber Lagging

| Part Number | Style | Durometer | Thickness | Width | Weight lbs |

|---|---|---|---|---|---|

| ASG-10X21.33-1/2-MSHA-TRL | Arrowhead | 60 | 1/2" | 10 | 42 |

| ASG-10X21.33-3/4-MSHA-TRL | Arrowhead | 60 | 3/4" | 10 | 56 |

| ASG-10X278-1/2-MSHA-TRL | Arrowhead | 65 | 1/2" | 10 | 626 |

| ASG-10X21.33-1/2-MSHA-PLN | Smooth | 60 | 1/2" | 10 | 51 |