A copper mine was experiencing high wear in their “pant-leg”…

Read More >ARMORITE® SKIRTBOARD CONVEYOR WEAR LINERS

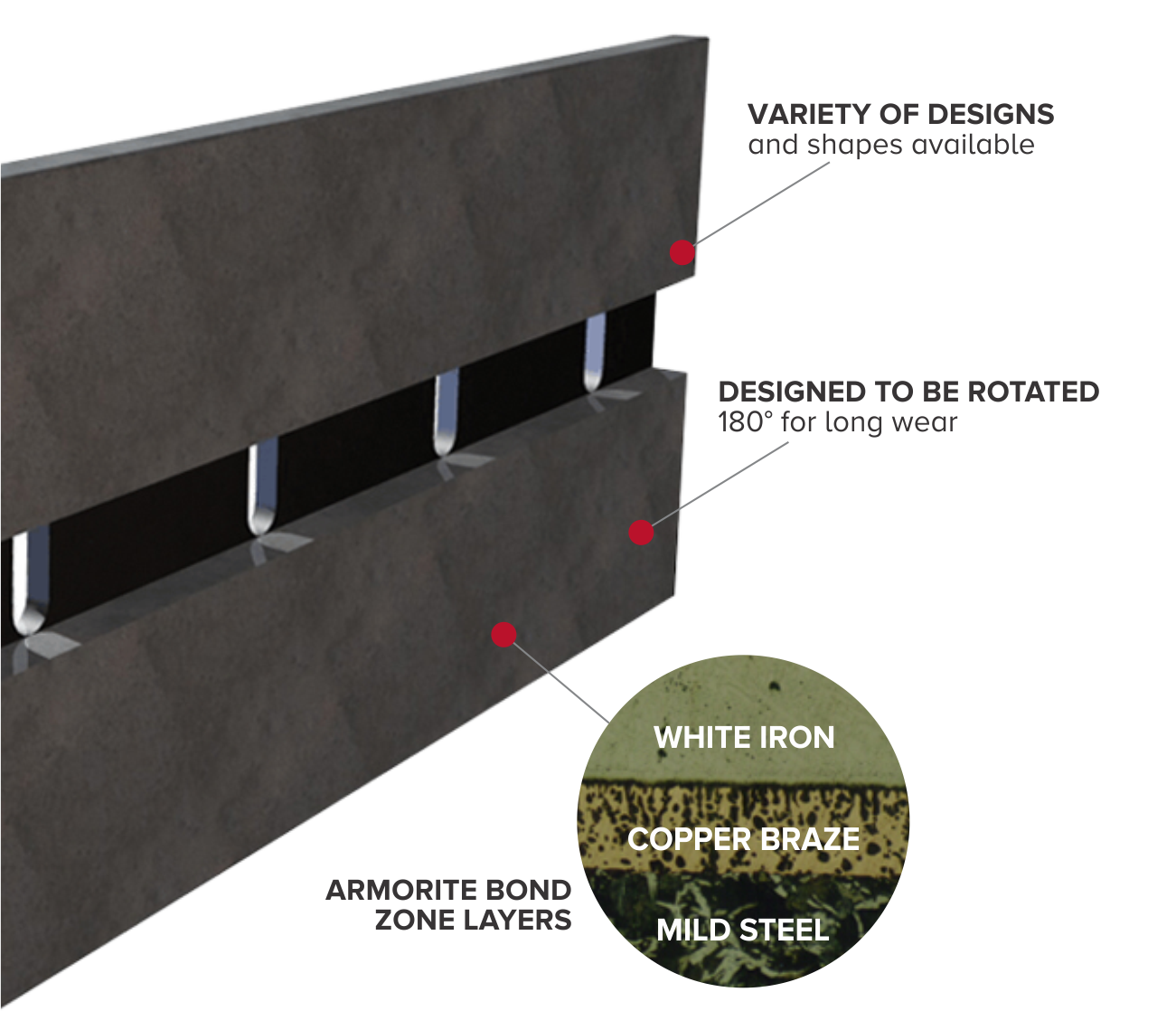

Design Features

- Reduces conveyor downtime – and maintenance costs.

- Designed to be rotated – 180º for long wear life.

- Custom designs – to meet customer requirements.

- High impact resistance – The skirt wear liner is produced from 20mm thick Armorite® that is enhanced with a 10mm thick mild steel producing a product that is 700 BHN with a high impact resistance.

- For all conveyors and transfer points – where the eradication of spillage or centralization of load is required.

- White Iron – Modified AS2027 15/3 Cr Mo

- Durable – Vacuumed brazed and liquid nitrogen cooled to achieve a high strength joint

- Mild steel backing – offers strength, machinability, and impact resistance

- Application – Can be welded in place, through-bolted, stud bolted, drilled, tapped, keyed.

PRODUCT SPECIFICATIONS

Applications – Chute Linings, Rock-Box Edges, Grizzly Caps/Screens, Transfer Points, Impact Plates, Distributor Plates, Arm/Hub Liners, Bin Liners Hopper Wear Plates, Divder/Splitter Bars, General Wear Protection, Liner PanelsPart Numbers

Armorite® Skirtboard Wear Liners

Thickness White Iron 3/4″ – Thichkness Base Plate 1/4″

| Part Number | Description | Length in. | Width in. | Thickness In. | Weight lbs |

|---|---|---|---|---|---|

| ASG-AMR-30X12X23.5 | Skirtboard Liner | 23-1/2 | 12 | 1-3/16 | 80 |

Solutions Case Studies