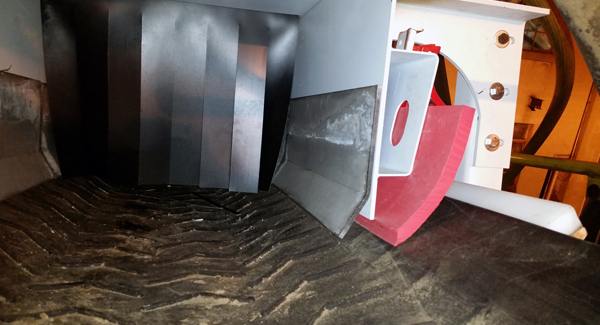

AR™ 400 HARDOX STEEL INTERNAL SKIRTBOARD LINERS

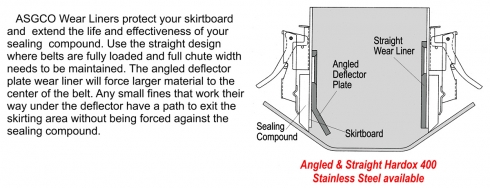

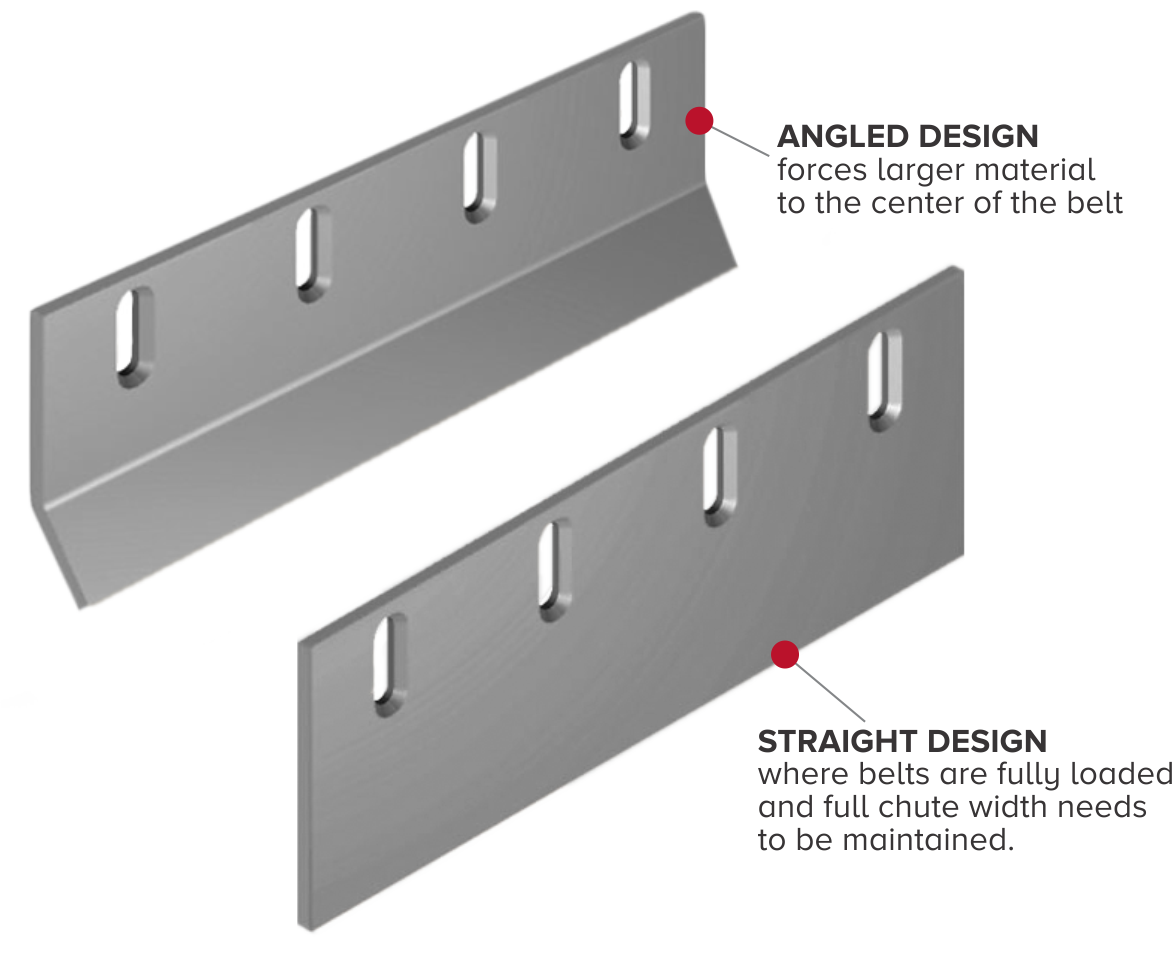

Use the straight design where belts are fully loaded and full chute width needs to be maintained. The angled deflector plate wear liner will force larger material to the center of the belt. Any small fines that work their way under the deflector have a path to exit the skirting area without being forced against the sealing compound.

- Lowest Cost Per Ton

- Material Flow with smooth laminar surface

- Reduces downtime

- Corrosion resistant

- Retrofit to worn out chutes and hoppers

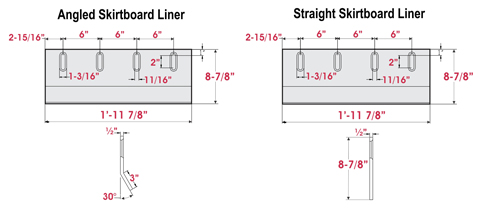

PRODUCT SPECIFICATIONS

Applications – Aggregate, Cement, Underground Mining, Mineral (Phosphate, Potash, Salt) Mining Weight – 30lbs Stainless Steel AvailablePart Numbers

AR™ 400 Hardox Steel Internal Wear Liner

Custom sizes are available

| Part Number | Description | Weight lbs |

|---|---|---|

| M-ASG-SKRT-LIN-HAR-24-1/2-A | Deflector Wearplate, Hardox 400, Angled | 30 |

| M-ASG-SKRT-LIN-HAR-24-1/2-S | Deflector Wearplate, Hardox 400, Straight | 30 |