PRIMARY BELT CLEANER REPLACEMENT BLADES FOR YOUR CONVEYOR

Design Features

- Effectively eliminate material carryback, reducing loss of material and clean up chores.

- Fewer blade changes, less maintenance downtime.

- Best price per performance of ANY blades in the market.

- Blades offered for the full line of ASGCO® belt cleaners, plus retrofit-replacements for many other manufacturers’ / OEM models.

- Quality blades backed up with our “Total Satisfaction” Guarantee.

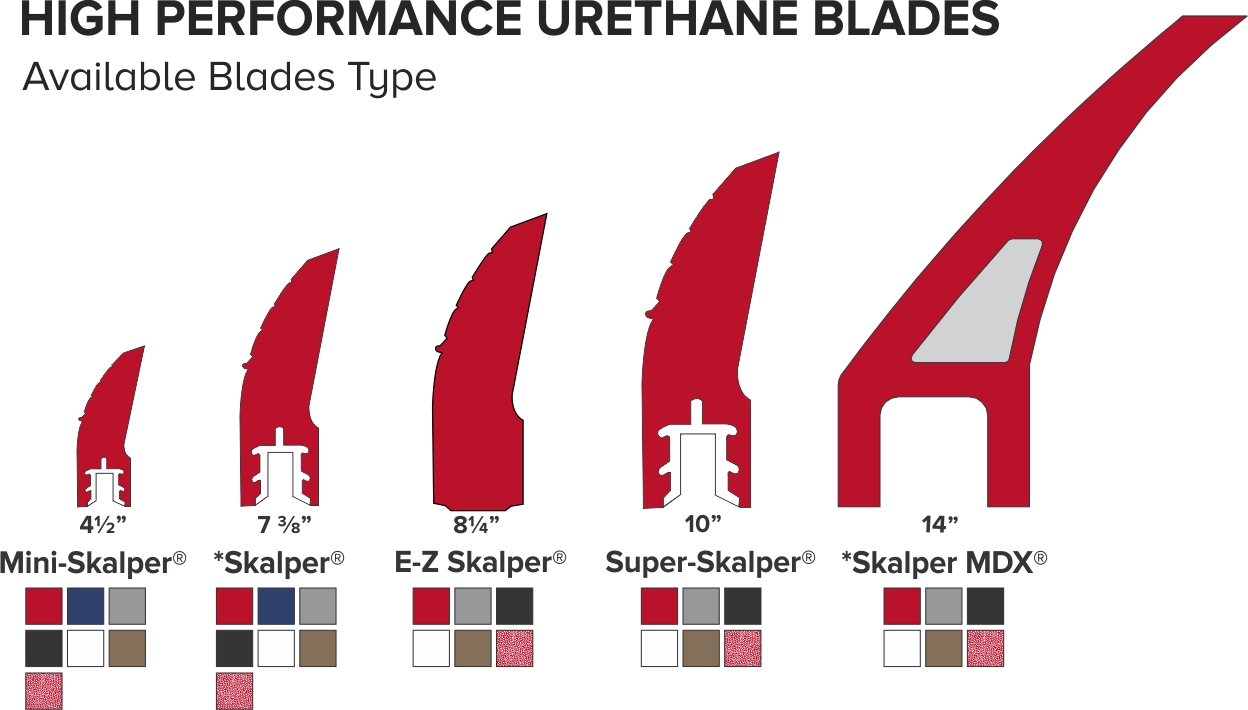

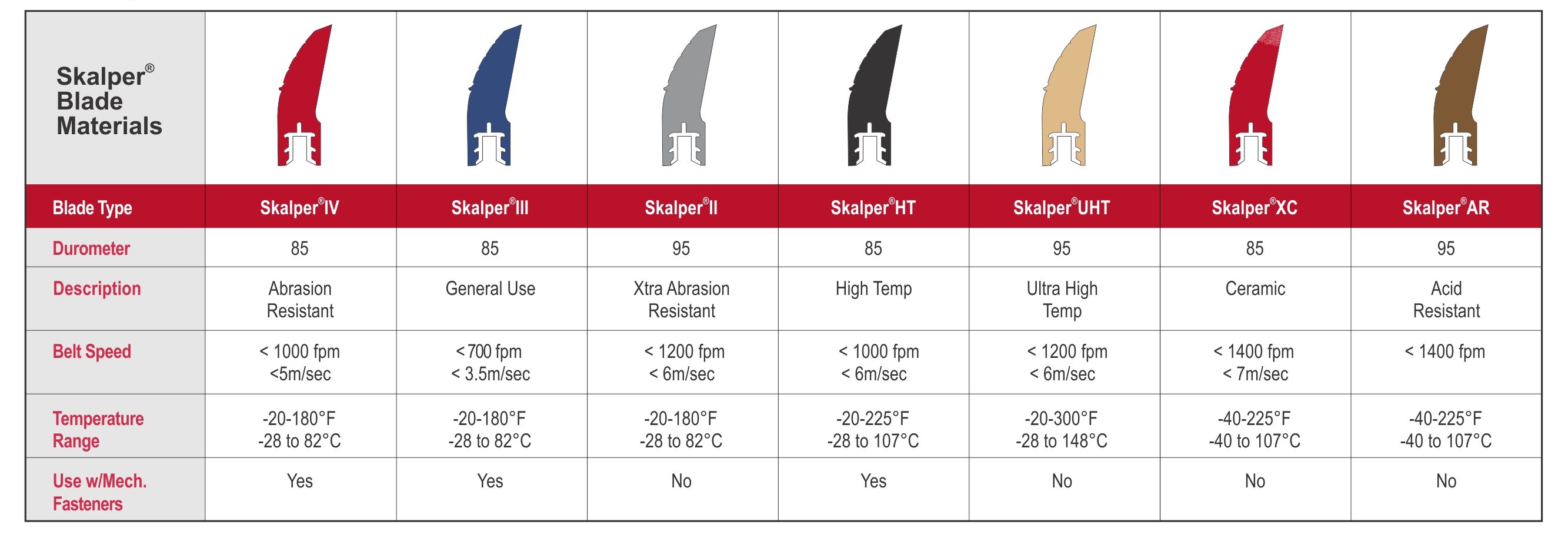

Skalper® Blade Options and Specifications

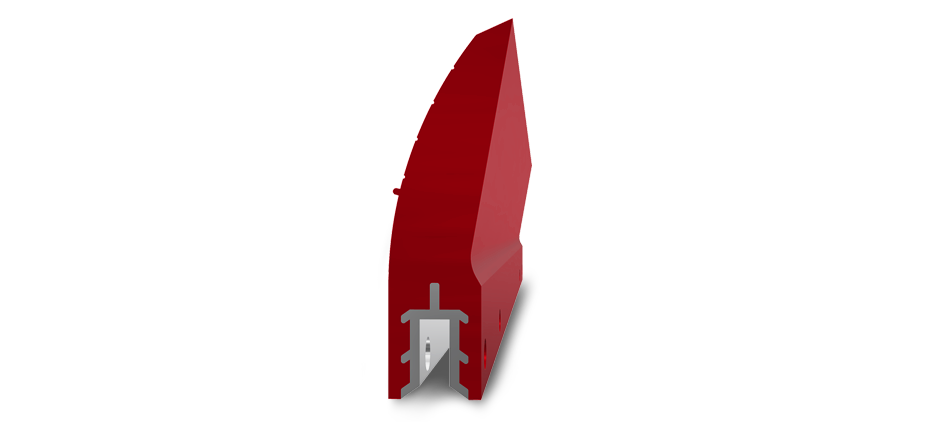

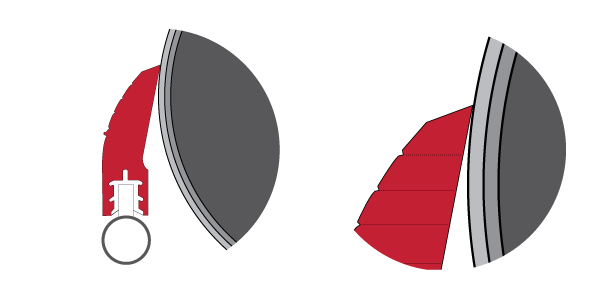

Blade Angle

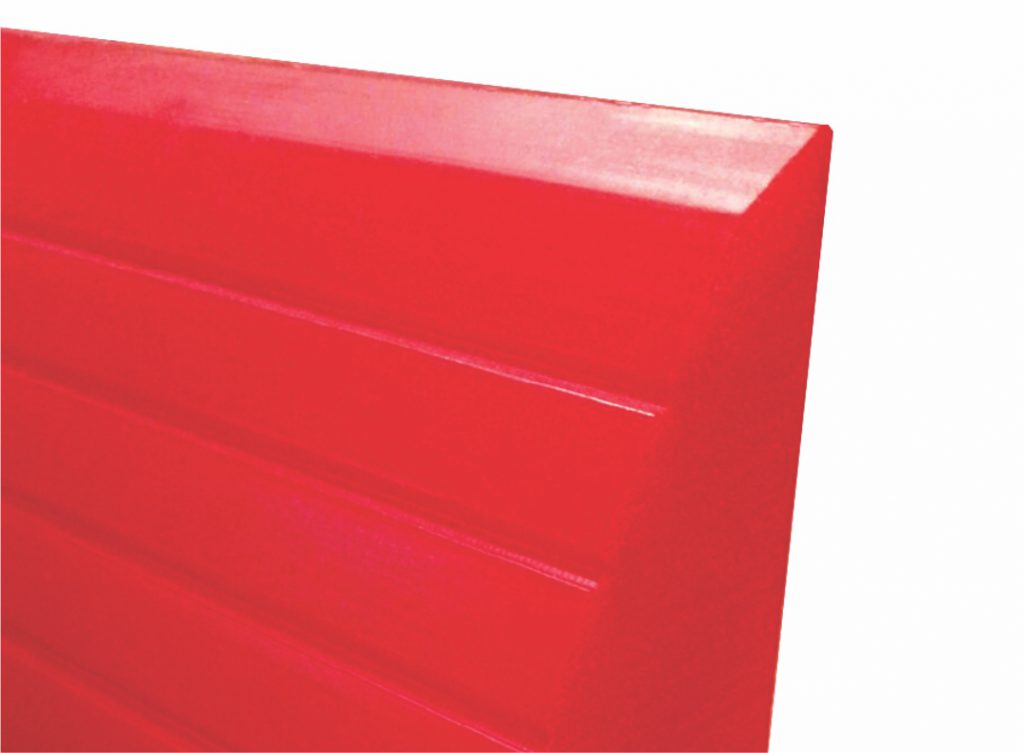

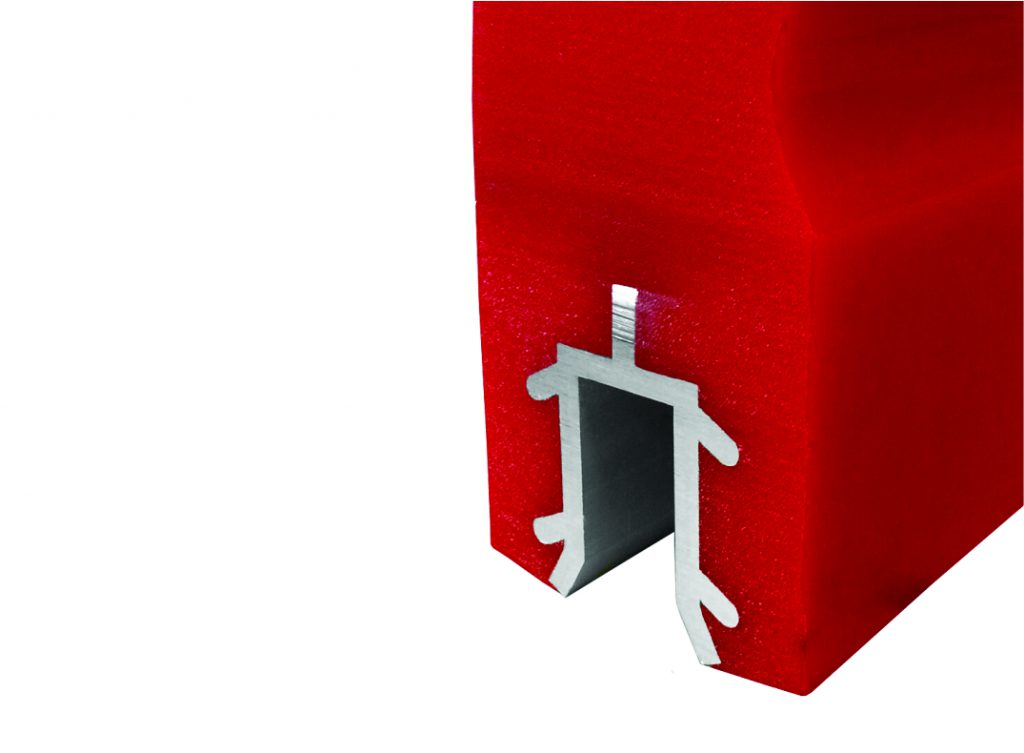

A flat pulley surface side of the blade ensures a sharp point of contact and material clearance. ASGCO®’s patented Skalper® Blade design maintains an effective cleaning edge throughout the life of the blade with its unique horizontal sipes/wear-grooves across the entire width of the blade cleaning edge and by the use of the arc-shaped back side of the blade to ensure a sharp cleaning edge.

Part Numbers

Mini-Skalper® Replacement Blades

Skalper® 4 – Abrasion Resistant / 85 Durometer / Belt Speed – <1000 fpm <5m/sec / Temp. Range -20-180°F -28 to 82°C

| Part Number | Blade Width in. | Blade Width mm. | Weight lbs |

|---|---|---|---|

| ASG-SK4M-12A | 12 | 300 | 3 |

| ASG-SK4M-18A | 18 | 450 | 4 |

| ASG-SK4M-24A | 24 | 600 | 6 |

| ASG-SK4M-30A | 30 | 750 | 7 |

| ASG-SK4M-36A | 36 | 900 | 9 |

| ASG-SK4M-42A | 42 | 1500 | 10 |

| ASG-SK4M-48A | 48 | 1200 | 12 |

| ASG-SK4M-54A | 54 | 1350 | 14 |

| ASG-SK4M-60A | 60 | 1500 | 15 |

| ASG-SK4M-66A | 66 | 1800 | 17 |

| ASG-SK4M-72A | 72 | 1800 | 18 |

| ASG-SK4M-84A | 84 | 2100 | 22 |

Part Numbers

Skalper® II, IV, HT & UHT Replacement Blade

Skalper® 2 – Extra Abrasion Resistant / 95 Durometer / Belt Speed – <1200 fpm <6m/sec / Temp. Range -20-180°F -28 to 82°C

Skalper® 4 – Abrasion Resistant / 85 Durometer / Belt Speed – <1000 fpm <5m/sec / Temp. Range -20-180°F -28 to 82°C

Skalper® HT – High Temp / 85 Durometer / Belt Speed – <1000 fpm <6m/sec / Temp. Range -20-225°F -28 to 107°C

Skalper® UHT – Ultra High Temp / 95 Durometer / Belt Speed – <1200 fpm <6m/sec / Temp. Range -20-300°F -28 to 148°C

* Please specify Blade Type * = Skalper® 2, 4, HT, UHT

| Part Number | Blade Width in. | Blade Width mm. | Weight lbs |

|---|---|---|---|

| ASG-SK*-12A-1 | 12 | 300 | 6 |

| ASG-SK*-18A-1 | 18 | 450 | 8 |

| ASG-SK*-24A-1 | 24 | 600 | 11 |

| ASG-SK*-30A-1 | 30 | 750 | 13 |

| ASG-SK*-36A-1 | 36 | 900 | 16 |

| ASG-SK*-42A-1 | 42 | 1050 | 19 |

| ASG-SK*-48A-1 | 48 | 1200 | 21 |

| ASG-SK*-54A-1 | 54 | 1350 | 24 |

| ASG-SK*-60A-1 | 60 | 1500 | 27 |

| ASG-SK*-66A-1 | 66 | 1650 | 30 |

| ASG-SK*-72A-1 | 72 | 1800 | 32 |

| ASG-SK*-78A-1 | 78 | 1950 | 34 |

| ASG-SK*-84A-1 | 84 | 2100 | 36 |

| ASG-SK*-90A-1 | 90 | 2250 | 38 |

| ASG-SK*-96A-1 | 96 | 2400 | 40 |

Part Numbers

E-Z Skalper® Replacement Blades (85 Durometer)

Mechanical or Vulcanized Splices

| Part Number | Blade Width in. | Blade Width mm. | Weight lbs |

|---|---|---|---|

| ASG-EZSK-18A | 18 | 450 | 9 |

| ASG-EZSK-24A | 24 | 600 | 12 |

| ASG-EZSK-30A | 30 | 750 | 15 |

| ASG-EZSK-36A | 36 | 1500 | 18 |

| ASG-EZSK-42A | 42 | 1500 | 21 |

| ASG-EZSK-48A | 48 | 1200 | 24 |

| ASG-EZSK-54A | 54 | 1350 | 27 |

| ASG-EZSK-60A | 60 | 1500 | 30 |

| ASG-EZSK-66A | 66 | 1650 | 33 |

| ASG-EZSK-72A | 72 | 1800 | 36 |

| ASG-EZSK-78A | 78 | 1950 | 39 |

| ASG-EZSK-84A | 84 | 2100 | 42 |

Part Numbers

Skalper® MDX Replacement Blades (Mine Duty)

Will also fit classic Head Shed HD Pre-Cleaner #CSHS-HD01MDX-Will also fit classic Head Shed HD Pre-Cleaner #CSHS-HD01

| Part Number | Blade Size | Color | Durometer | Weight lbs |

|---|---|---|---|---|

| ASG-MDX-BLD-6-PRI | 6"x 14" | Red | 85 | 4 |

| ASG-MDXCER-BLD-6-PRI-B | 6"x14" | Red | 85 | 4 |