GUARANTEED MINE TOUGH!

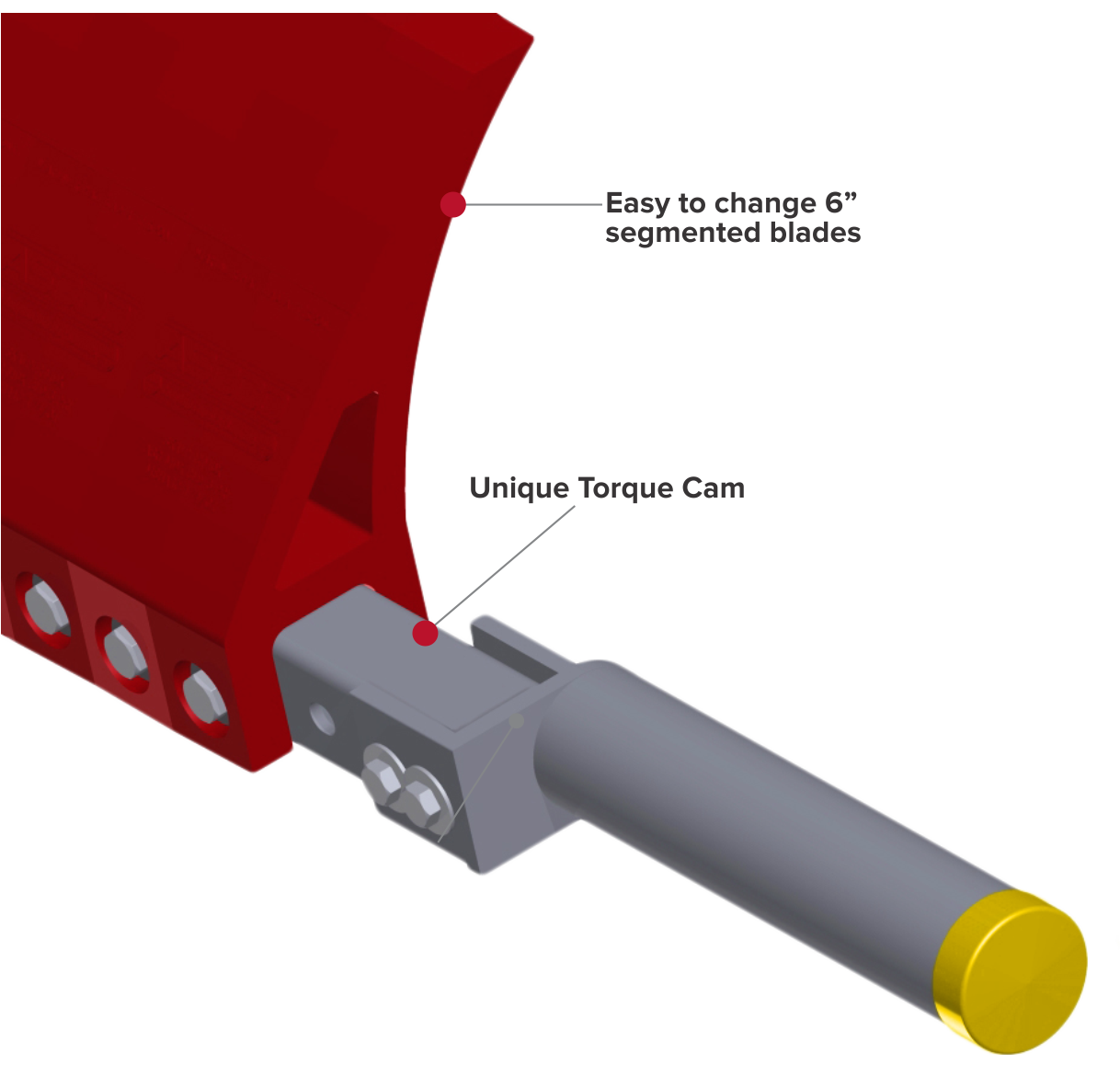

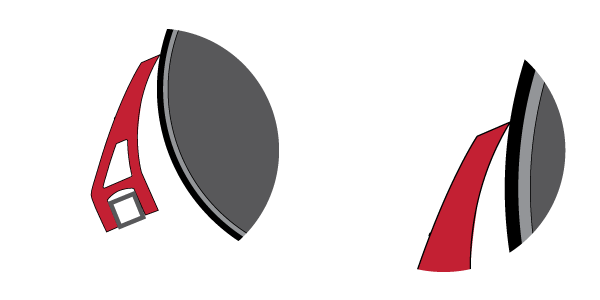

Design Features

Part Numbers

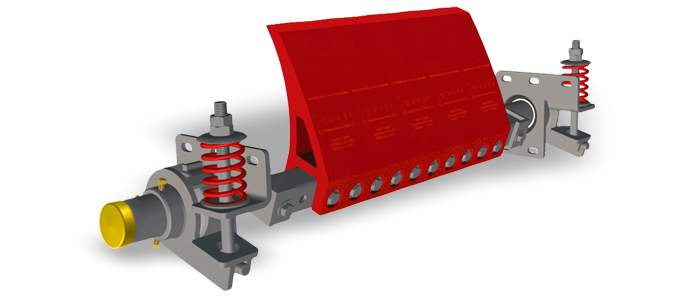

Skalper® MDX with Spring-Shoc Tensioner System

Skalper® MDX with Spring Tensioner System with all Necessary Mouting Components in one Economical Package. Each System includes: one (1) Skalper® MDX Blade, (1) Transverse Mountion Element, (1) Mounting Assembly Kit, (1) Right and Left Primary MDX Torque Arms

| Part Number | Belt Width in. | Belt Width mm. | Blade Width in. | Blade Width mm. | Weight lbs |

|---|---|---|---|---|---|

| M-SK4MDX-SYS-48-ST-42 | 48 | 1200 | 42 | 1050 | 235 |

| M-SK4MDX-SYS-54-ST-48 | 54 | 1350 | 48 | 1200 | 251 |

| M-SK4MDX-SYS-60-ST-54 | 60 | 1500 | 54 | 1350 | 266 |

| M-SK4MDX-SYS-66-ST-60 | 66 | 1650 | 60 | 1500 | 281 |

| M-SK4MDX-SYS-72-ST-60 | 72 | 1800 | 60 | 1500 | 287 |

| M-SK4MDX-SYS-84-ST-72 | 84 | 2100 | 72 | 1800 | 317 |

| M-SK4MDX-SYS-96-ST-84 | 96 | 2400 | 84 | 2100 | 348 |

Part Numbers

Skalper® MDX with Air-Shoc™ Tensioner System

NEMA 4 Air Control Box, Includes Hoses and Regulator

| Part Number | Belt Width in. | Belt Width mm. | Blade Width in. | Blade Width mm. | Weight lbs |

|---|---|---|---|---|---|

| M-SK4MDX-SYS-48-AS-42 | 48 | 1200 | 42 | 1050 | 227 |

| M-SK4MDX-SYS-54-AS-48 | 54 | 1350 | 48 | 1200 | 243 |

| M-SK4MDX-SYS-60-AS-54 | 60 | 1500 | 54 | 1350 | 258 |

| M-SK4MDX-SYS-66-AS-60 | 66 | 1600 | 60 | 1500 | 273 |

| M-SK4MDX-SYS-72-AS-60 | 72 | 1800 | 60 | 1500 | 279 |

| M-SK4MDX-SYS-84-AS-72 | 84 | 2100 | 72 | 1800 | 309 |

| M-SK4MDX-SYS-96-AS-84 | 96 | 2400 | 84 | 2100 | 340 |