TACKLE THE TOUGHEST BULK MATERIAL HANDLING APPLICATIONS

Design Features

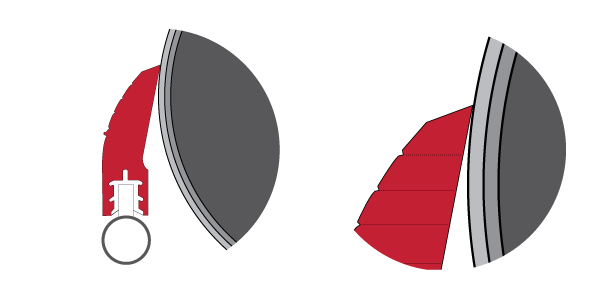

- Excellent Performance – of our patented Super-Skalper® Blade design maintains an effective cleaning edge throughout the life of the blade with its unique horizontal sipes/wear-grooves across the entire width of the blade cleaning edge and by the use of the arc-shaped back side of the blade to ensure a sharp cleaning edge.

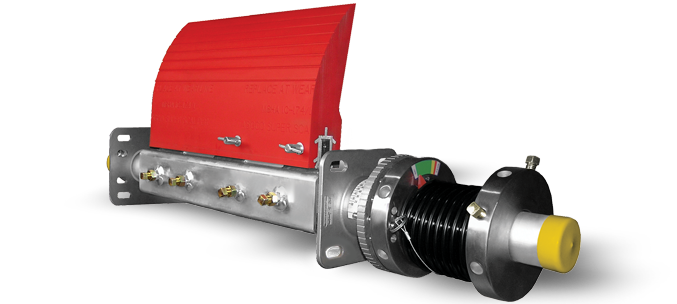

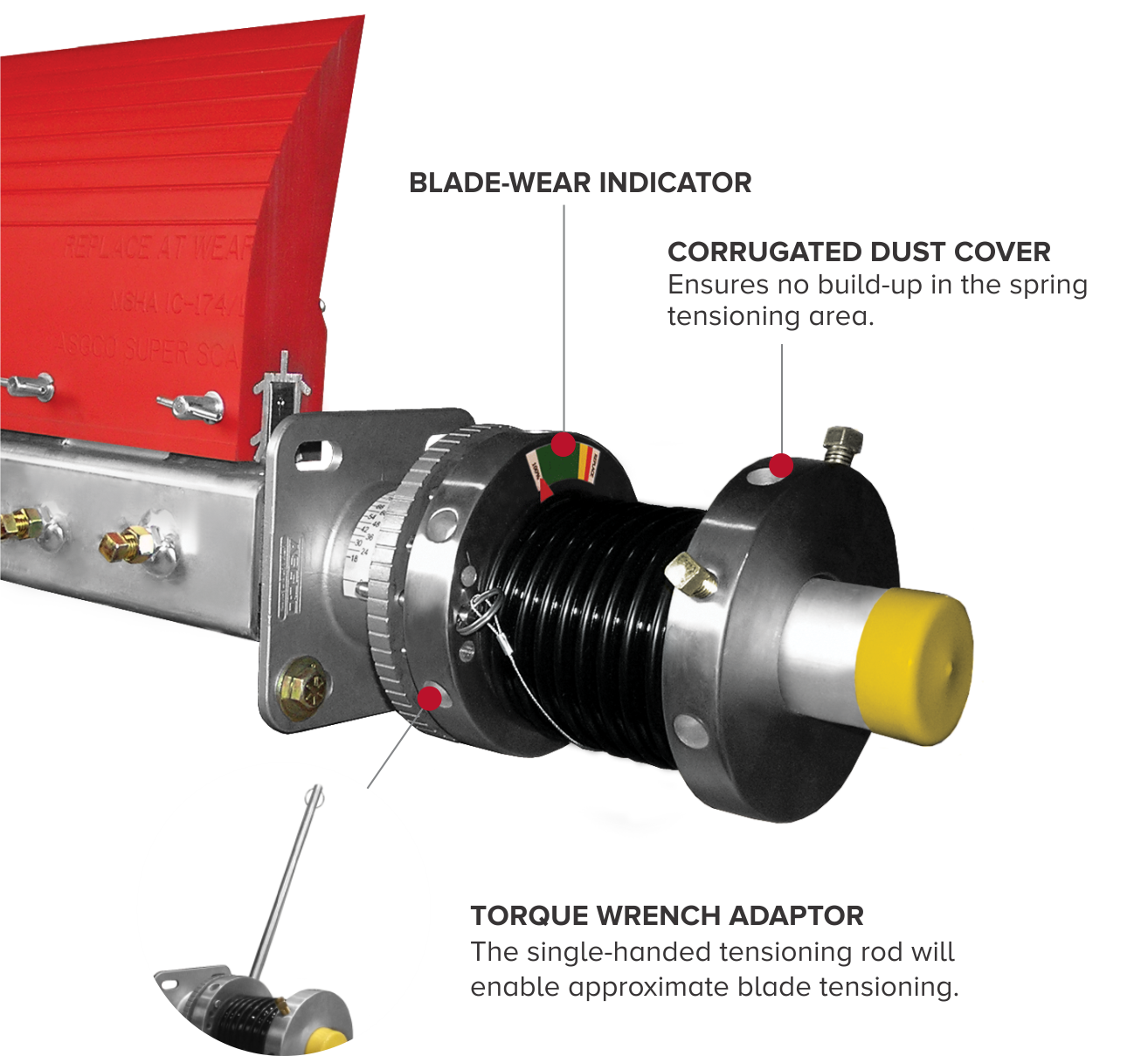

- E-Z Torque® Tensioner – (lifetime warranty) patented – made of all 304 stainless steel mounting plates, collars and springs allows the blades to self adjust throughout the entire life of the blade and is the most robust and accurate belt cleaner tensioner in the industry.

- One-Time Tensioning – the patented E-Z Torque® tensioner maintains constant tension throughout the life of the blade.

- Blade-Wear Indicator – allows you to monitor blade wear easily without having to shut the system down for inspection.

- Torque Spring – provides a greater degree of tensioning per inch of blade, verses compression springs which require more tensioning adjustment for the life of the blade.

- Rubber Corrugated Dust Covers and UHMW Bushings – ensures no build-up in the spring tensioning area and provides smooth non-binding tensioning.

- Quick-Change Blade – stainless steel pin blade change-out system, one-minute, no-tool.

- Optional – Ceramic (XC) blade available for high speed tonnage conveyor systems operation.

- Easily Maintained – and tensioned from one side of the conveyor.

- MSHA Accepted – #MSHA IC – 174/1

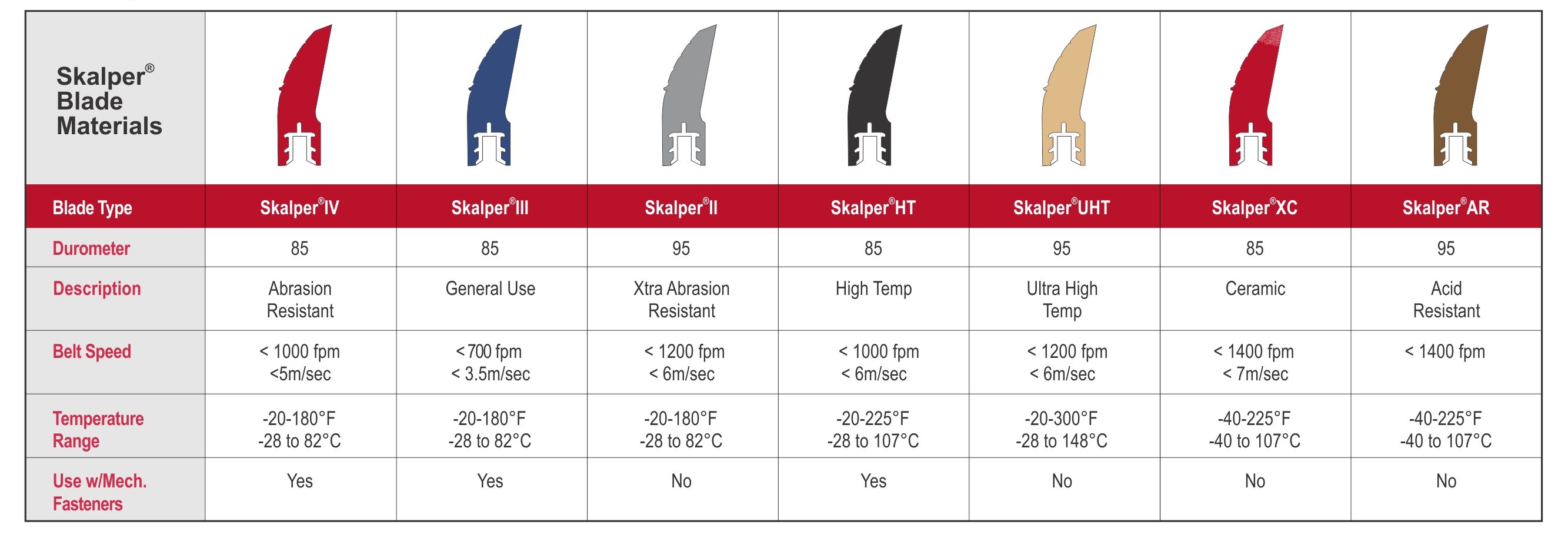

Skalper® Blade Options and Specifications

Part Numbers

Super-Skalper® Primary Full Belt Width W/E-Z Torque® Tensioner

Super-Skalper Systems with all necessary mounting components in one economical package. Each System includes: one (1) Super-Skalper Blade, (1) Transverse Mounting Element, (1) Mounting Assembly Kit, (1) E-Z Torque Tensioner. ** Please specify Blade Type: SK2, SK4, HT when ordering **

| Part Number | Belt Width in. | Belt Width mm. | Blade Width in. | Blade Width mm. | Weight lbs |

|---|---|---|---|---|---|

| M-SSK*-SYS-36-EZT-1 | 36 | 900 | 36 | 900 | 118 |

| M-SSK*-SYS-42-EZT-1 | 42 | 1050 | 42 | 1050 | 130 |

| M-SSK*-SYS-48-2EZT-1 | 48 | 1200 | 48 | 1200 | 156 |

| M-SSK*-SYS-54-2EZT-1 | 54 | 1350 | 54 | 1350 | 168 |

| M-SSK*-SYS-60-2EZT-1 | 60 | 1500 | 60 | 1500 | 180 |

| M-SSK*-SYS-72-2EZT-1 | 72 | 1800 | 72 | 1800 | 204 |

| M-SSK*-SYS-84-2EZT-1 | 84 | 2100 | 84 | 2100 | 228 |

| M-SSK*-SYS-96-2EZT-1 | 96 | 2400 | 96 | 2400 | 252 |

Part Numbers

Super-Skalper® with E-Z Torque® (Belt Width-6)

Super-Skalper Systems with all necessary mounting components in one economical package. Eash System includes: one (1) Super-Skalper Blade, (1) Transverse Mounting Element, (1) Mounting Assembly Kit, (1) E-Z Torque Tensioner. ** Please specify Blade Type: SK2, SK4, HT, UHT when ordering**

| Part Number | Belt Width in. | Belt Width mm. | Blade Width in. | Blade Width mm. | Weight lbs |

|---|---|---|---|---|---|

| M-SSK*-SYS-36-EZT-30-1 | 36 | 900 | 30 | 750 | 113 |

| M-SSK*-SYS-42-EZT-36-1 | 42 | 1050 | 36 | 900 | 125 |

| M-SSK*-SYS-48-2EZT-42-1 | 48 | 1200 | 42 | 1050 | 151 |

| M-SSK*-SYS-54-2EZT-48-1 | 54 | 1350 | 48 | 1200 | 163 |

| M-SSK*-SYS-60-2EZT-54-1 | 60 | 1500 | 54 | 1350 | 175 |

| M-SSK*-SYS-72-2EZT-66-1 | 72 | 1800 | 66 | 1650 | 199 |

| M-SSK*-SYS-84-2EZT-78-1 | 84 | 2100 | 78 | 2000 | 223 |

| M-SSK*-SYS-96-2EZT-90-1 | 96 | 2400 | 90 | 2250 | 247 |

Part Numbers

Super-Skalper® with E-Z Torque® (Belt Width-12)

Super-Skalper Systems with all Necessary Mounting Components in one Economical Package. Eash System includes: one (1) Super-Skalper Blade, (1) Transverse Mounting Element, (1) Mounting Assembly Kit, (1) E-Z Troque Tensioner. ** Please Specify Blade Type: SK2, SK4, HT, UHT when ordering**

| Part Number | Belt Width in. | Belt Width mm. | Blade Width in. | Blade Width mm. | Weight lbs |

|---|---|---|---|---|---|

| M-SSK*-SYS-36-EZT-24-1 | 36 | 900 | 24 | 600 | 113 |

| M-SSK*-SYS-42-EZT-30-1 | 42 | 1050 | 30 | 750 | 125 |

| M-SSK*-SYS-48-2EZT-36-1 | 48 | 1200 | 36 | 900 | 151 |

| M-SSK*-SYS-54-2EZT-42-1 | 54 | 1350 | 42 | 1050 | 163 |

| M-SSK*-SYS-60-2EZT-48-1 | 60 | 1500 | 48 | 1200 | 175 |

| M-SSK*-SYS-72-2EZT-60-1 | 72 | 1800 | 60 | 1500 | 199 |

| M-SSK*-SYS-84-2EZT-72-1 | 84 | 2100 | 72 | 1800 | 223 |

| M-SSK*-SYS-96-2EZT-84-1 | 96 | 2400 | 84 | 2100 | 247 |