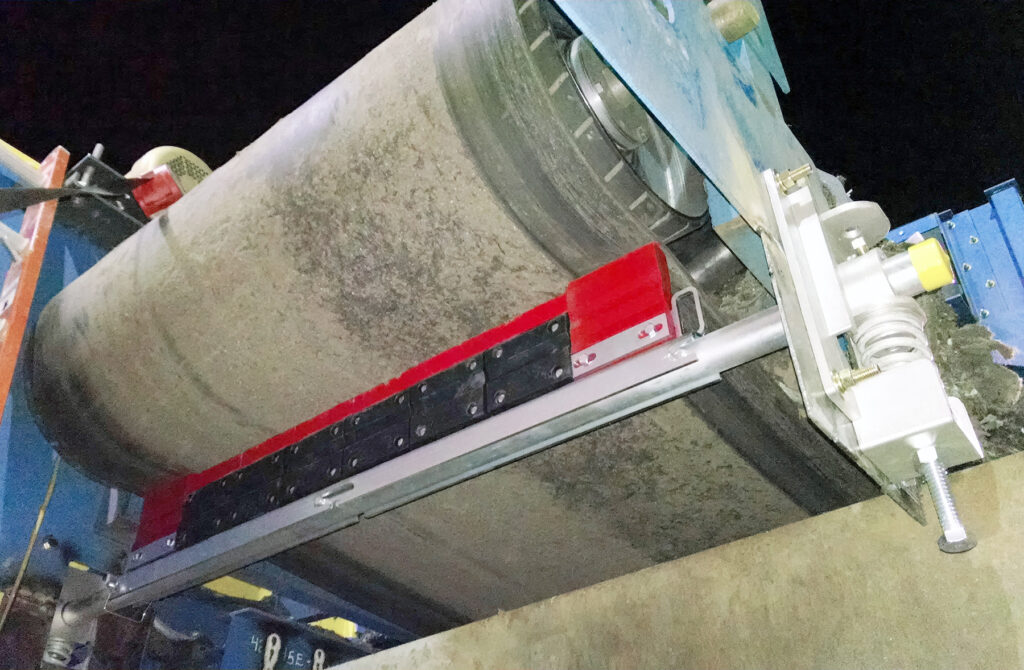

Challenge: This recycling facility needed to solve their carry-back issues by…

Read More >FLEXIBLE SOLUTION SUITABLE FOR REVERSING CONVEYOR BELTS

Design Features

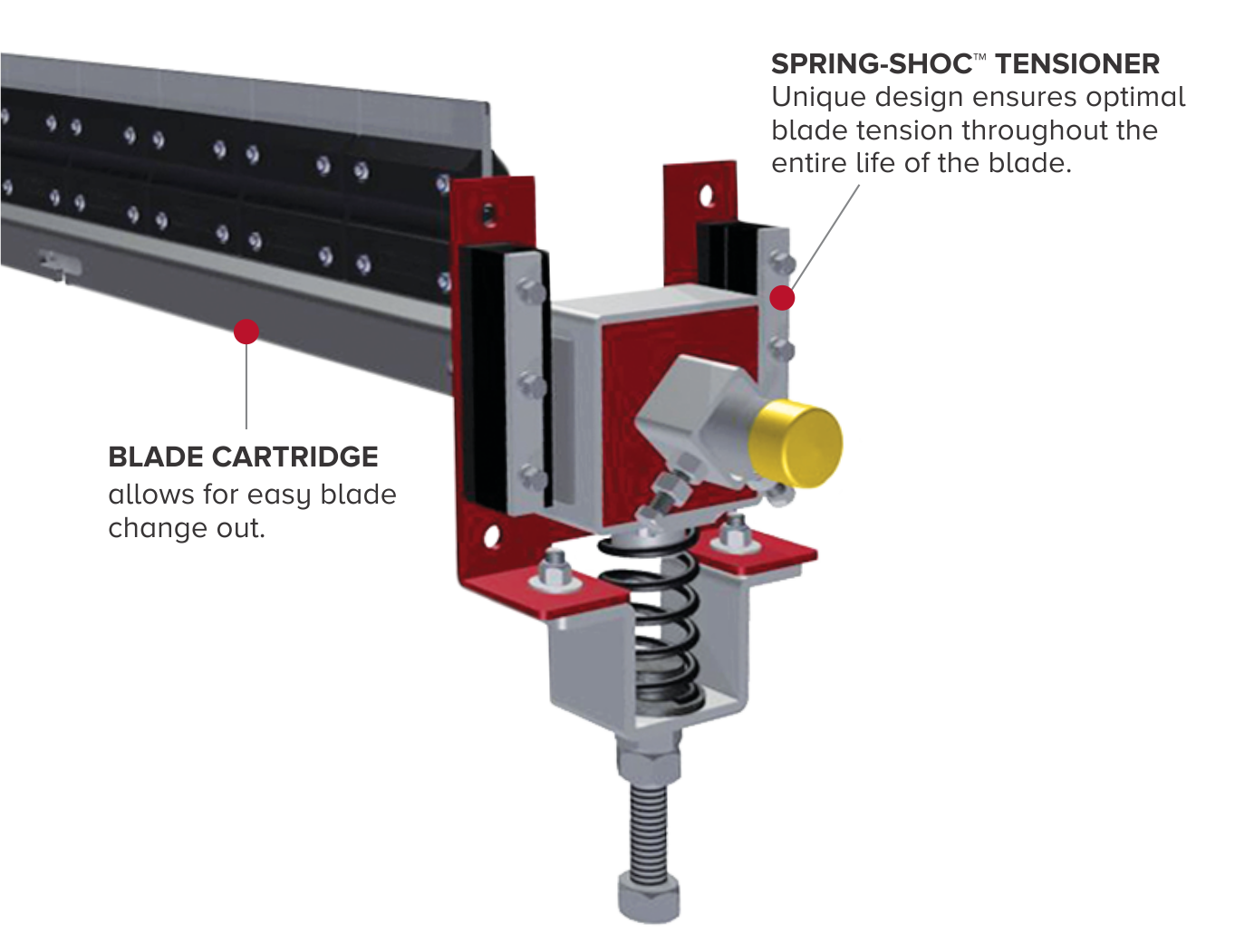

- Complete Cleaning – with our combination of 6″ (150mm) cleaning blades that are either tungsten carbide, AR 400 steel or urethane, will be recommended based on your specific application, are independently tensioned by its own rubber cushion to maintain a consistent blade-to-belt pressure.

- Blade Cartridge – allows for easy change out of scraper blades from either side of the conveyor.

- Designed for Reversing Conveyors – such as shuttles or conveyors that roll back, trippers, due to its unique two-way rubber cushions.

- Tensioned – by either our Spring-Shoc™, Bolt-Up™ or Duo-Spring™ tensioners for constant blade pressure, reducing blade re-tensioning maintenance and ensure high cleaning efficiency throughout the life of the blade. Duo-Spring™ (patent pending) is a heavy duty, steel spring tensioner that can be either positioned as a “push-up” or “pull-up” configuration depending on your installation mounting requirements.

PRODUCT SPECIFICATIONS

- Maximum Belt Speed – 1000 fpm (5.0 m/sec)

- Application – Aggregate, Cement, Coal Fired Power Plants, Mineral (Phosphate, Potash, Salt) Mining, Wood Processing Recycling

Part Numbers

TORO™ Spring-Shoc™ Tensioner with C-Tipped Carbide

TORO C-Tips: Belt Speed: <1000 fpm <5m/sec / -20-180°F -28 to 82°C

Tensioners Mounting Capability: Pull-Up or Push-Up

| Part Number | Belt Width in. | Belt Width mm. | Weight lbs |

|---|---|---|---|

| M-TORO-SYS-18C-ST | 18 | 450 | 94 |

| M-TORO-SYS-24C-ST | 24 | 600 | 103 |

| M-TORO-SYS-30C-ST | 30 | 750 | 112 |

| M-TORO-SYS-36C-ST | 36 | 900 | 121 |

| M-TORO-SYS-42C-ST | 42 | 1070 | 130 |

| M-TORO-SYS-48C-ST | 48 | 1200 | 139 |

| M-TORO-SYS-54C-ST | 54 | 1350 | 148 |

| M-TORO-SYS-60C-ST | 60 | 1500 | 157 |

| M-TORO-SYS-66C-ST | 66 | 1600 | 166 |

| M-TORO-SYS-72C-ST | 72 | 1800 | 175 |

| M-TORO-SYS-84C-ST | 84 | 2100 | 193 |

Part Numbers

TORO™ Spring-Shoc™ Tensioner with F-Tipped AR Blades

TORO F-Tips: Belt Speed: <1000 fpm <5m/sec / -20-180°F -28 to 82°C

Tensioners Mounting Capability: Pull-Up or Push-Up

AR- Acid Resistant

| Part Number | Belt Width in. | Belt Width mm. | Weight lbs |

|---|---|---|---|

| M-TORO-SYS-18AR-ST | 18 | 450 | 94 |

| M-TORO-SYS-24AR-ST | 24 | 600 | 103 |

| M-TORO-SYS-30AR-ST | 30 | 750 | 112 |

| M-TORO-SYS-36AR-ST | 36 | 900 | 121 |

| M-TORO-SYS-42AR-ST | 42 | 1070 | 130 |

| M-TORO-SYS-48AR-ST | 48 | 1200 | 139 |

| M-TORO-SYS-54AR-ST | 54 | 1350 | 148 |

| M-TORO-SYS-60AR-ST | 60 | 1500 | 157 |

| M-TORO-SYS-66AR-ST | 66 | 1600 | 166 |

| M-TORO-SYS-72AR-ST | 72 | 1800 | 173 |

| M-TORO-SYS-84AR-ST | 84 | 2100 | 193 |

Part Numbers

TORO™ Spring-Shoc™ Tensioner with U-Tipped Urethane Blades

TORO U-Tips: Belt Speed: <1000 fpm <5m/sec / -20-180°F -28 to 82°C

Tensioners Mounting Capability: Pull-Up or Push-Up

| Part Number | Belt Width in. | Belt Width mm. | Weight lbs |

|---|---|---|---|

| M-TORO-SYS-18UB-ST | 18 | 450 | 63 |

| M-TORO-SYS-24UB-ST | 24 | 600 | 67 |

| M-TORO-SYS-30UB-ST | 30 | 750 | 71 |

| M-TORO-SYS-36UB-ST | 36 | 900 | 75 |

| M-TORO-SYS-42UB-ST | 42 | 1050 | 79 |

| M-TORO-SYS-48UB-ST | 48 | 1200 | 83 |

| M-TORO-SYS-54UB-ST | 54 | 1350 | 87 |

| M-TORO-SYS-60UB-ST | 60 | 1500 | 60 |

| M-TORO-SYS-66UB-ST | 66 | 1600 | 95 |

| M-TORO-SYS-72UB-ST | 72 | 1800 | 99 |

| M-TORO-SYS-84UB-ST | 84 | 2100 | 103 |

Literature Downloads

Solutions Case Studies

Mining Quarry Solves Carry-Back problem with TORO® Belt Cleaner. (more…)

Read More >