Challenge: The customer had a large/reoccurring spill problem on top…

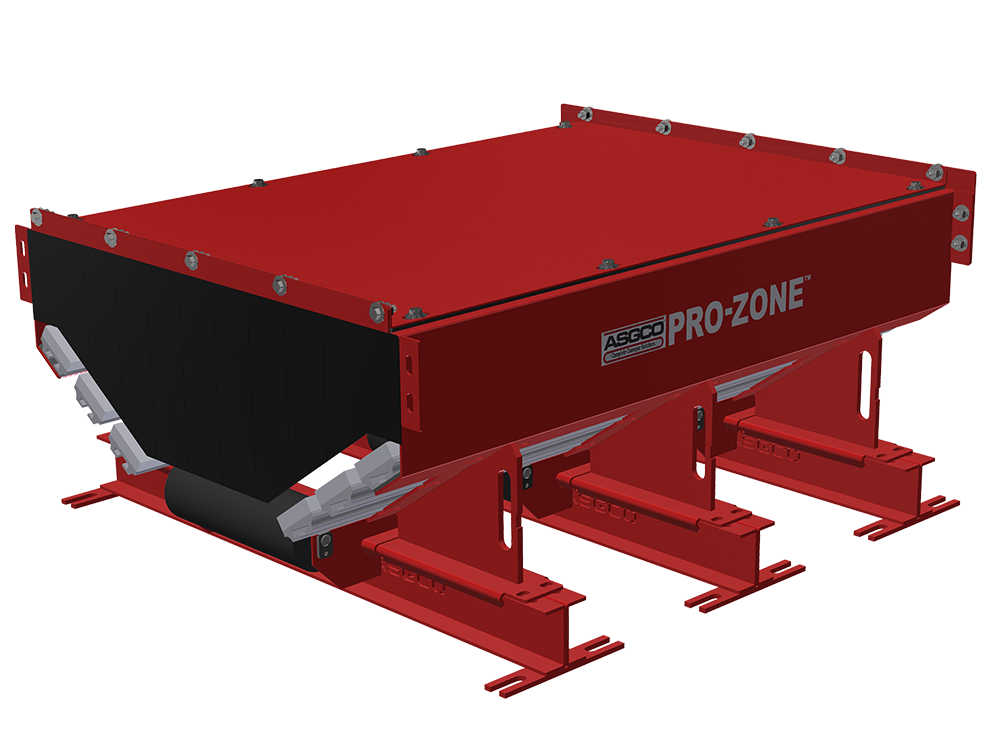

Read More >The world’s first advanced containment and dust control solution for conveyed bulk material products.

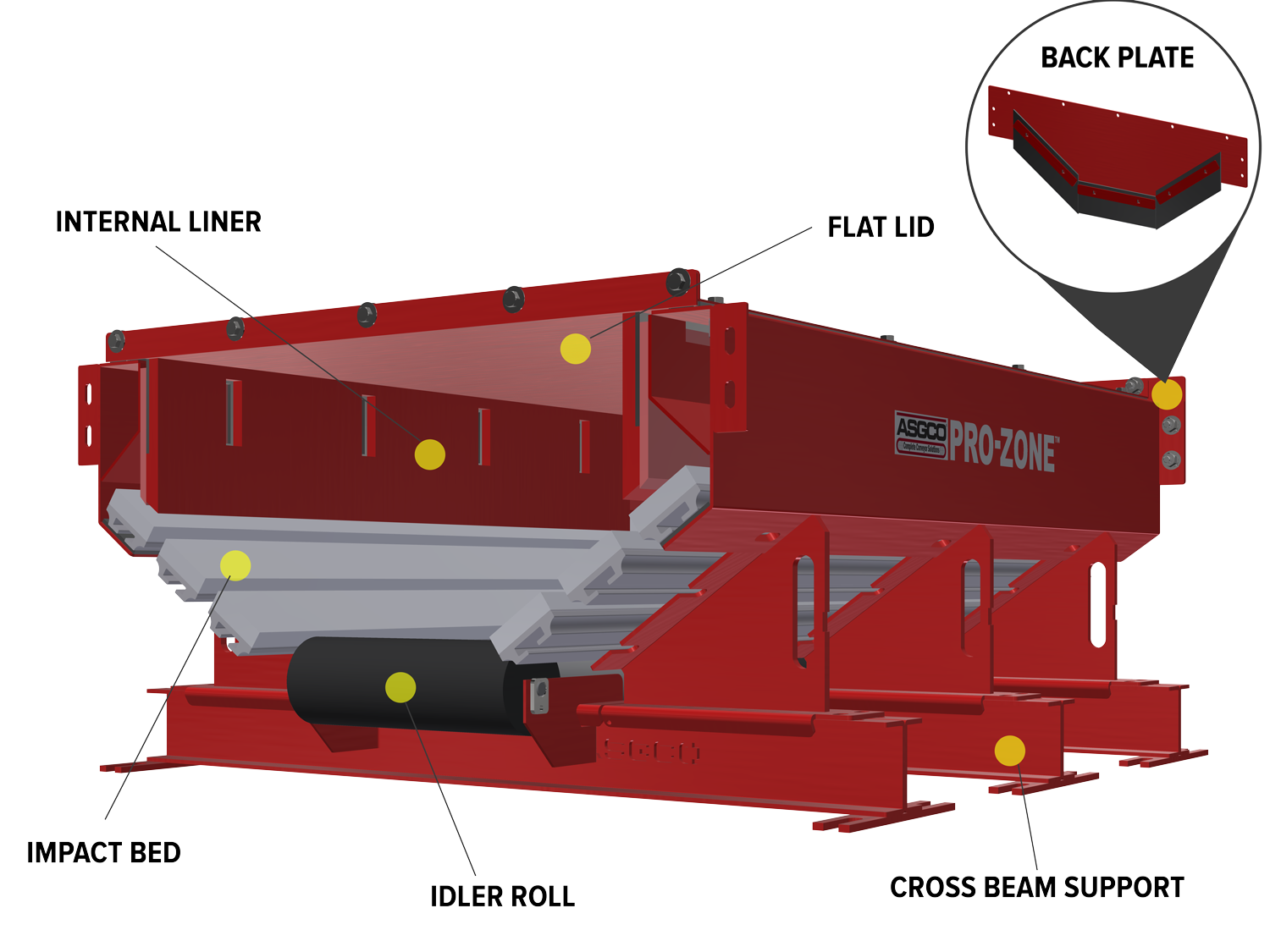

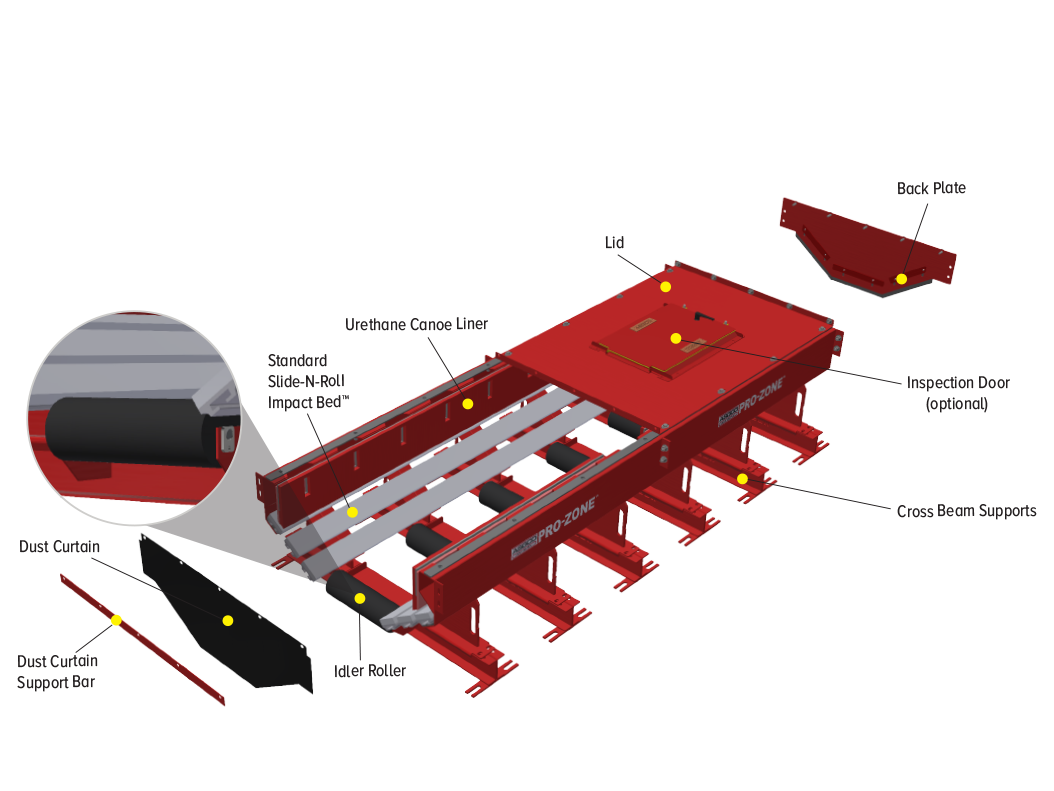

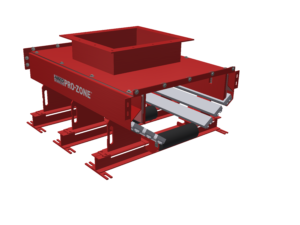

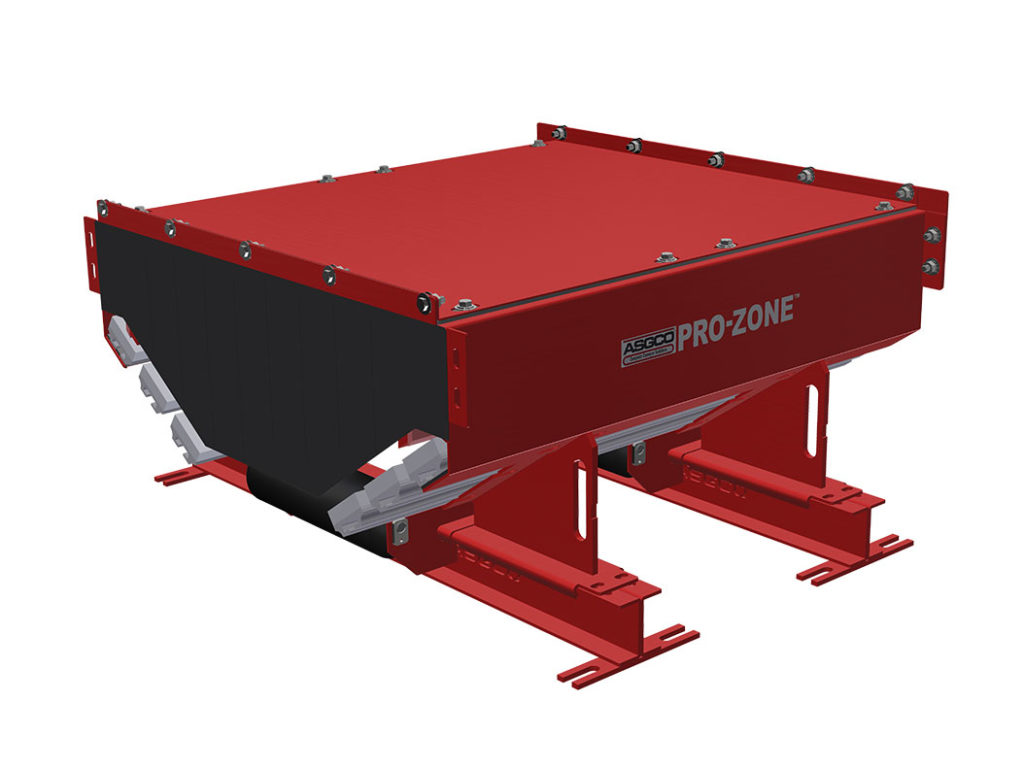

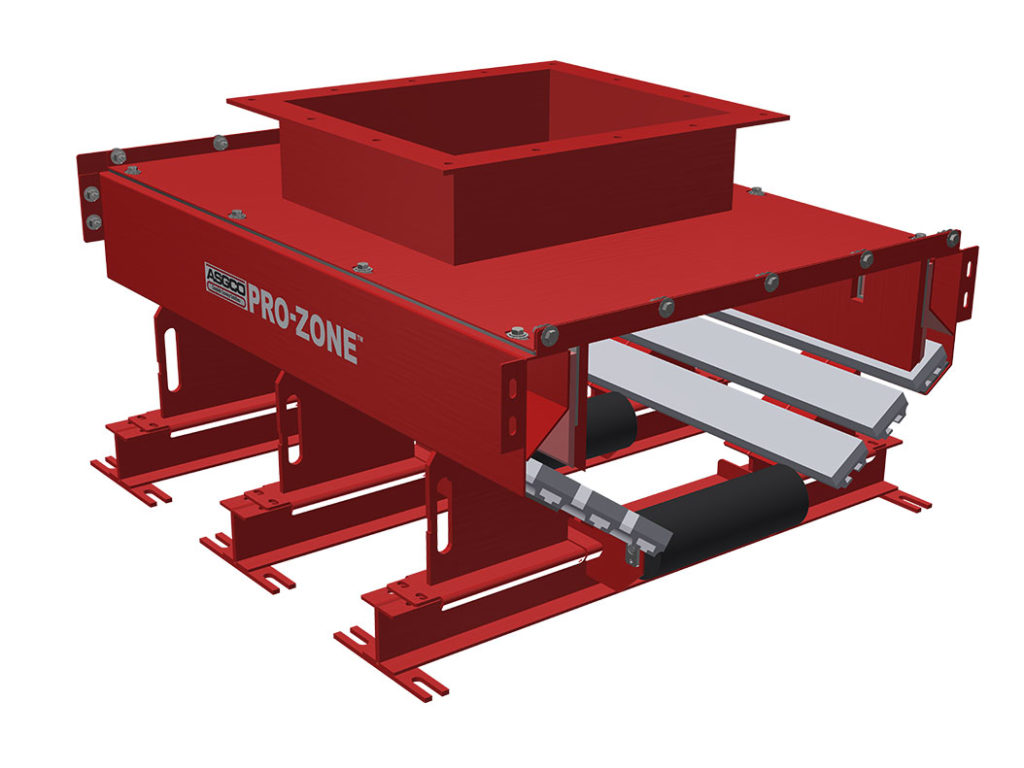

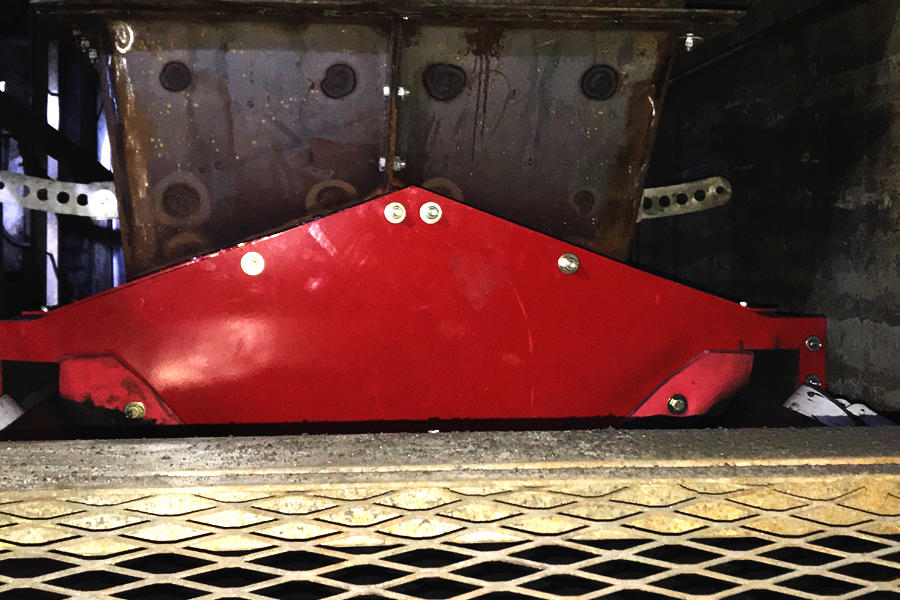

This “skirt-less”, fully self-contained system is comprised of our Slide-N-Roll beds with our removable, “slide-out” steel side supports with UHMW bars and easily removable center rolls. Walls, internal sealing system, dust curtains, back plate and flat lids completely enclose the entire system.

Design Features

- Environmentally Friendly due to significant reduction of airborne and fugitive dust.

- Increased Productivity and longer conveyor belt life because the completely sealed load zone helps eliminate material turbulence and conveyor belt cover abrasion.

- Lower Maintenance Costs by having a “skirt-less”, fully contained system that needs no adjustments of metal skirtboards or rubber skirting.

- Modular Design can be installed in any combination of 4’ (1200mm) or 5’ (1500mm) lengths to completely cover load zone area. Quickly removable lids, slide-out side sections and removable center rolls aid in the installation and maintenance of the system.

- Made in the USA completely engineered, designed, fabricated and stock in the USA.

PRODUCT SPECIFICATIONS

Applications – Underground Mining, Coal Fired Power Plant, Hard Rock Mining, Steel Mills, Iron Ore, Metals (Copper/gold), Aggregate, Mineral (Phosphate, Potash, Salt) Mining, Sand & Gravel, Redi-Mix and Asphalt, Cement, Wood Processing Recycling Pro-Zone™ Systems – Can be custom made to meet desire goal. 4’ (1200mm) & 5’ (1500mm) section available Trough Angle – available in 20°, 35° and 45°Part Numbers

Pro-Zone™ with 2 Supports

Center rolls not Included

| Part Number | Belt Width in. | Blade Width mm. | Weight Lbs |

|---|---|---|---|

| M-ASGPZ-18-2-48-2-(XX) | 18 | 450 | 215 |

| M-ASGPZ-24-4-48-2-(XX) | 24 | 600 | 287 |

| M-ASGPZ-30-4-48-2-(XX) | 30 | 750 | 359 |

| M-ASGPZ-36-6-48-2-(XX) | 36 | 900 | 430 |

| M-ASGPZ-42-6-48-2-(XX) | 42 | 1050 | 502 |

| M-ASGPZ-48-6-48-2-(XX) | 48 | 1200 | 574 |

| M-ASGPZ-54-8-48-2-(XX) | 54 | 1350 | 646 |

| M-ASGPZ-60-8-48-2-(XX) | 60 | 1500 | 717 |

| M-ASGPZ-72-10-48-2-(XX) | 72 | 1800 | 861 |

Part Numbers

Pro-Zone™ with 3 Supports

Center rolls not included

| Part Number | Belt Width in. | Belt Width mm. | Weight Lbs. |

|---|---|---|---|

| M-ASGPZ-18-2-60-3-(XX) | 18 | 600 | 262 |

| M-ASGPZ-24-4-60-3-(XX) | 24 | 600 | 350 |

| M-ASGPZ-30-4-60-3-(XX) | 30 | 750 | 437 |

| M-ASGPZ-36-6-60-3-(XX) | 36 | 900 | 525 |

| M-ASGPZ-42-6-60-3-(XX) | 42 | 1050 | 612 |

| M-ASGPZ-48-6-60-3-(XX) | 48 | 1200 | 699 |

| M-ASGPZ-54-8-60-3-(XX) | 54 | 1350 | 717 |

| M-ASGPZ-60-8-60-3-(XX) | 60 | 1500 | 874 |

| M-ASGPZ-72-10-60-3-(XX) | 72 | 1800 | 1049 |

Literature Downloads

Solutions Case Studies

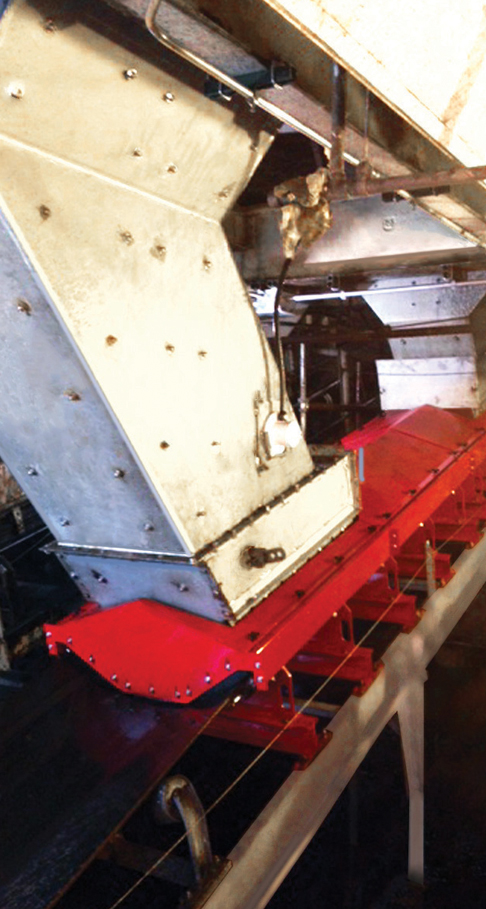

Objective: To design a new self-contained material load zone that…

Read More >

In today’s coal fired power plants, it is important to…

Read More >