DESIGNED FOR MODERATE IMPACT AND SEVERE ABRASION.

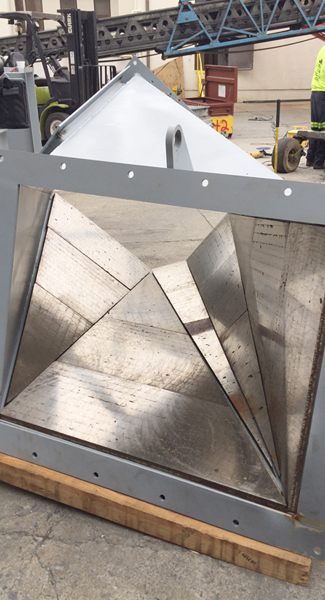

The overlay surface of CCO plate will consist of a series of beads with numerous hairline cracks in them. These properly spaced crosscheck cracks are a natural phenomenon and are beneficial to the material. The cracks propagate through the overlay and end at the fusion line.

Cutting – Plasma burning, air arc, abrasive saw or water jet.

Welding – Our CCO overlay plate can be joined by welding the substrate to substrate using 309 weld wire/rod.

Bending – Using a press brake, forming should be perpendicular to the weld pass direction. Plate rolling should be performed in the directions of the overlay beads.