X-WEAR™ CERAMIC WEARPLATE

Design Features

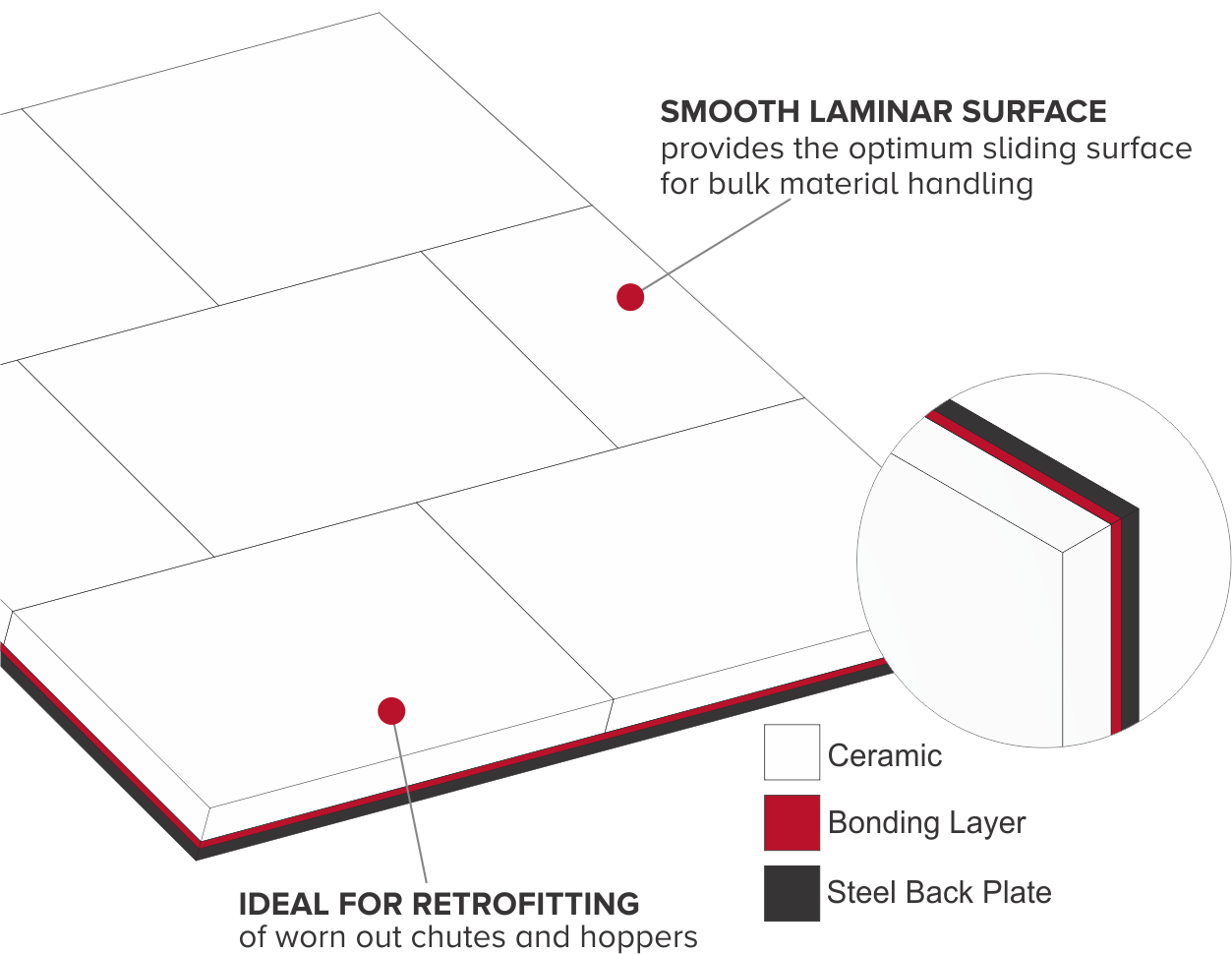

- Material Flow – The smooth laminar surface of X-Wear™ Ceramic provides the optimum sliding surface for material handling.

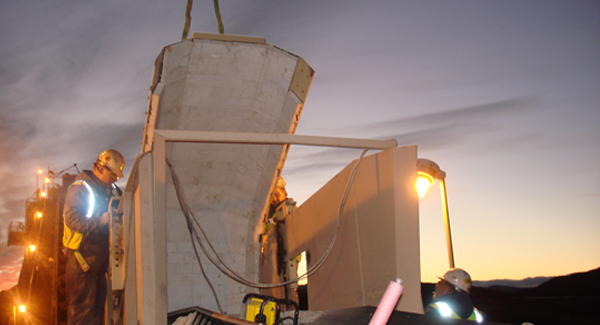

- Custom – The remarkable structural integrity of X-Wear™ Ceramic makes it ideal for direct retrofitting of worn out chutes and hoppers without expensive repairs.

- Noise Reduction – X-Wear™Ceramic’s energy absorbing design dramatically reduces noise.

- 1/4” Steel Backing – suitable for stud welding or plug welding.

- ½”, 3/4”, 1” 1½”, and 2” ceramic available.

PRODUCT SPECIFICATIONS

Applications – Transfer points in conveyor systems, Screen Chutes, Launder Liners, Chute Liners Ceramic Bonded – 1/4” steel plate using impact resistant urethane epoxy Custom sizes available at customers request.Part Numbers

X-Wear™ Ceramic Wearplate

| Part Number | Width in. | Length In. | Ceramic Thickness In. | Steel Thickness In. | Weight lbs |

|---|---|---|---|---|---|

| M-ASG-XW-12X12X1/2 | 12 | 12 | 1/2 | 1/4 | 21 |

| M-ASG-XW-12X12X3/4 | 12 | 12 | 3/4 | 1/4 | 25 |

| M-ASG-XW-12X12X1 | 12 | 12 | 1 | 1/4 | 29 |

| M-ASG-XW-12X12X2 | 12 | 12 | 2 | 1/4 | 47 |