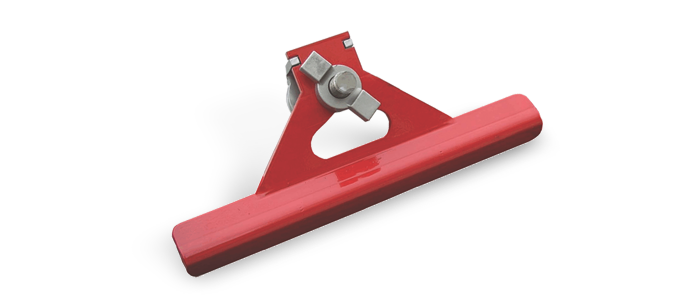

CLAMP-MOUNT MDX™ (MINE DUTY) CONVEYOR SKIRTBOARD SEALING SYSTEM

Design Features

- Increase Performance – by helping to eliminate spillage and dust in the conveyor loading zone.

- Reduce Conveyor Downtime – by the simple clamp adjustment and release to allow repositioning or changing out skirting in minutes versus hours, without tools.

- Mine Duty Construction – 18” or 24″ heavy duty clamp system with keeper, fabricated from 3/8” thick steel for aggressive mining applications.

- Easy Adjustment – Patent pending adjustment nut is cast 304 stainless steel.

- Versatile – Can be used with any of ASGCO skirtboard sealing compounds.

- Keeper & Nut Feature – The keeper and nut features a 1” Acme thread which can be adjusted by using a hammer or a wrench.

- Will Automatically Adjust – To any thickness from ¼” to 1¼”.

- Mine Duty Style

PRODUCT SPECIFICATIONS

Replacement Parts – MDX Keeper, MDX Clamp Nut Belt Widths – MDX 18” (457 mmm), MDX-2 24” (609 mm) Weight – MDX 10.4 Lbs, MDX-2 11 Lbs Length – MDX 18”, MDX-2 24”Part Numbers

Clamp-Mount™ MDX

| Part Number | Width | Weight lbs |

|---|---|---|

| M-ASG-CK-1-MDX | 18" | 10.4 |

| M-ASG-CK-1-MDX-2 | 24" | 11 |