DESIGNED TO DISCHARGE FUGITIVE MATERIAL FROM ONE SIDE OF THE CONVEYOR SYSTEM.

Design Features

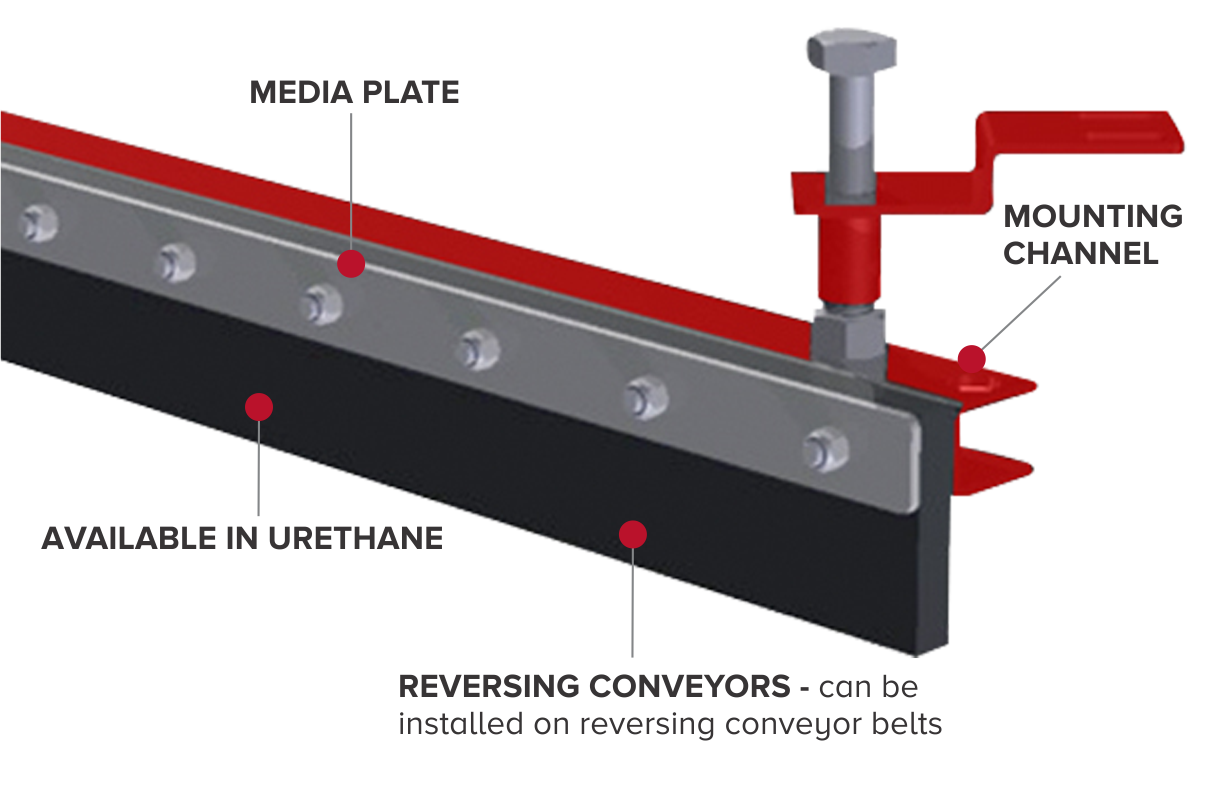

- Provides Effective – cleaning of the return side of the belt, protecting your tail pulley and the conveyor belt.

- Reversing Conveyors – can be installed on reversing conveyor belts.

- Easy Maintenance – simple and easy to install and maintain

- Diagonal plow discharges – material from one side of the belt

- Available – with rubber or urethane plow material

DESIGNED TO DIVERT DEBRIS TO ONE SIDE OF THE CONVEYOR

The plow deflects material from the belt that would normally be caught between the belt and a pulley, causing damage to the belt.

- Belt Direction is reversible

- Belt Width 18″-96″

- Can be Installed before the tail pulley or take-up pulley

- No maintenance needed

Product Specifications

Maximum Belt Speed – 1000fpm (5.0 m/sec) Applications – Coal Fired Power Plants, Hard Rock Mining, Underground Mining, Coal Preparation Plants, Steel Mills, Iron Ore, Aggregate, Metals (copper/gold) Mining, Mineral (Phosphate, Potash, Salt) Mining, Bulk Shipping TerminalPart Numbers

Diagonal Plow System (Rubber)

| Part Number | Belt Width in. | Belt Width mm. | Weight lbs |

|---|---|---|---|

| M-ASG-DP-18-1 | 18 | 450 | 36 |

| M-ASG-DP-24-1 | 24 | 600 | 39 |

| M-ASG-DP-30-1 | 30 | 750 | 50 |

| M-ASG-DP-36-1 | 36 | 900 | 60 |

| M-ASG-DP-42-1 | 42 | 1070 | 70 |

| M-ASG-DP-48-1 | 48 | 1200 | 80 |

| M-ASG-DP-54-1 | 54 | 1350 | 90 |

| M-ASG-DP-60-1 | 60 | 1500 | 100 |

| M-ASG-DP-66-1 | 66 | 1600 | 116 |

| M-ASG-DP-72-1 | 72 | 1800 | 130 |

| M-ASG-DP-84-1 | 84 | 2100 | 140 |

Part Numbers

Diagonal Plow System (Urethane)

| Part Number | Belt Width in. | Belt Width mm. | Weight lbs |

|---|---|---|---|

| M-ASG-DP-18-URE-1 | 18 | 450 | 36 |

| M-ASG-DP-24-URE-1 | 24 | 600 | 39 |

| M-ASG-DP-30-URE-1 | 30 | 750 | 50 |

| M-ASG-DP-36-URE-1 | 36 | 900 | 60 |

| M-ASG-DP-42-URE-1 | 42 | 1050 | 70 |

| M-ASG-DP-48-URE-1 | 48 | 1200 | 80 |

| M-ASG-DP-54-URE-1 | 54 | 1350 | 90 |

| M-ASG-DP-60-URE-1 | 60 | 1500 | 100 |

| M-ASG-DP-66-URE-1 | 66 | 11650 | 115 |

| M-ASG-DP-72-URE-1 | 72 | 1800 | 130 |

| M-ASG-DP-84-URE-1 | 84 | 2100 | 140 |