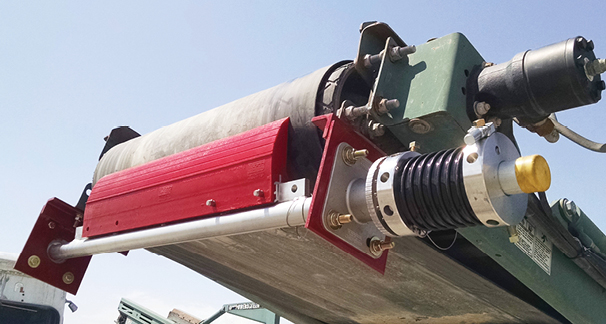

Constant exposure to salt moisture, copper concentrate and high humidity…

Read More >ELIMINATE YOUR CONVEYOR CARRY-BACK PROBLEMS!

Design Features

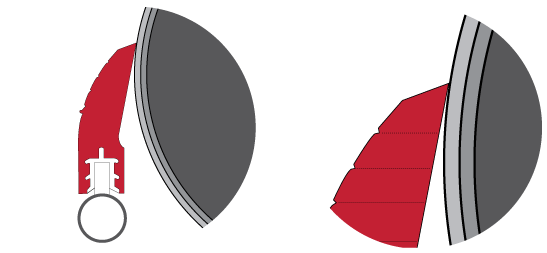

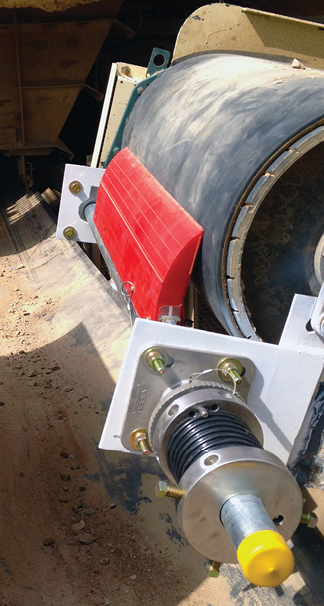

- Excellent Performance – of our patented Skalper® Blade design maintains an effective cleaning edge throughout the life of the blade with its unique horizontal sipes/wear-grooves across the entire width of the blade cleaning edge and by the use of the arc-shaped back side of the blade to ensure a sharp cleaning edge.

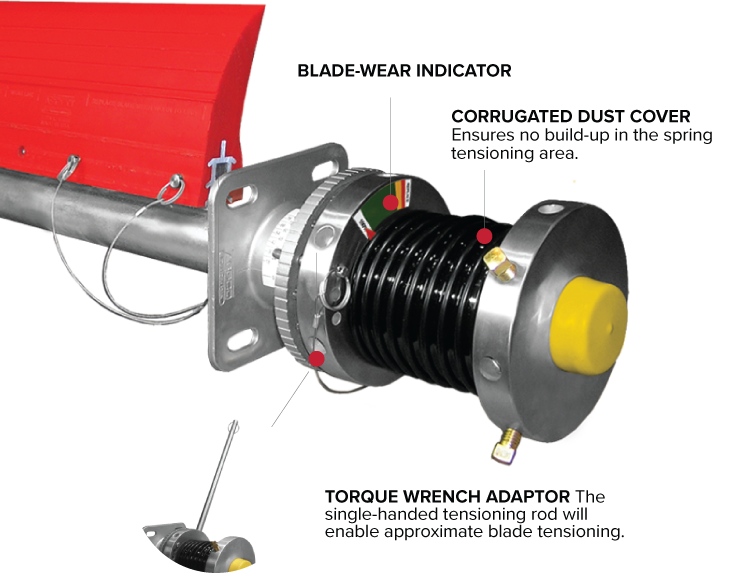

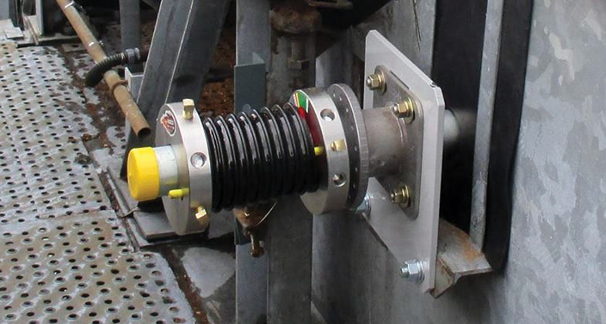

- One-Time Tensioning – the patented E-Z Torque® tensioner maintains constant tension throughout the life of the blade.

- Blade-Wear Indicator – allows to monitor blade wear easily without having to shut the system down for inspection.

- Torque Spring – provides a greater degree of tensioning per inch of blade, verses compression springs which require more tensioning adjustment for the life of the blade.

- Rubber Corrugated Dust Covers and UHMW Bushings – ensures no build-up in the spring tensioning area and provides smooth non-binding tensioning.

- Quick-Change Blade – stainless steel pin blade change-out system uses no-tools.

- Easily Maintained – and tensioned from one side of the conveyor.

- MSHA Accepted – #MSHA IC – 174/1

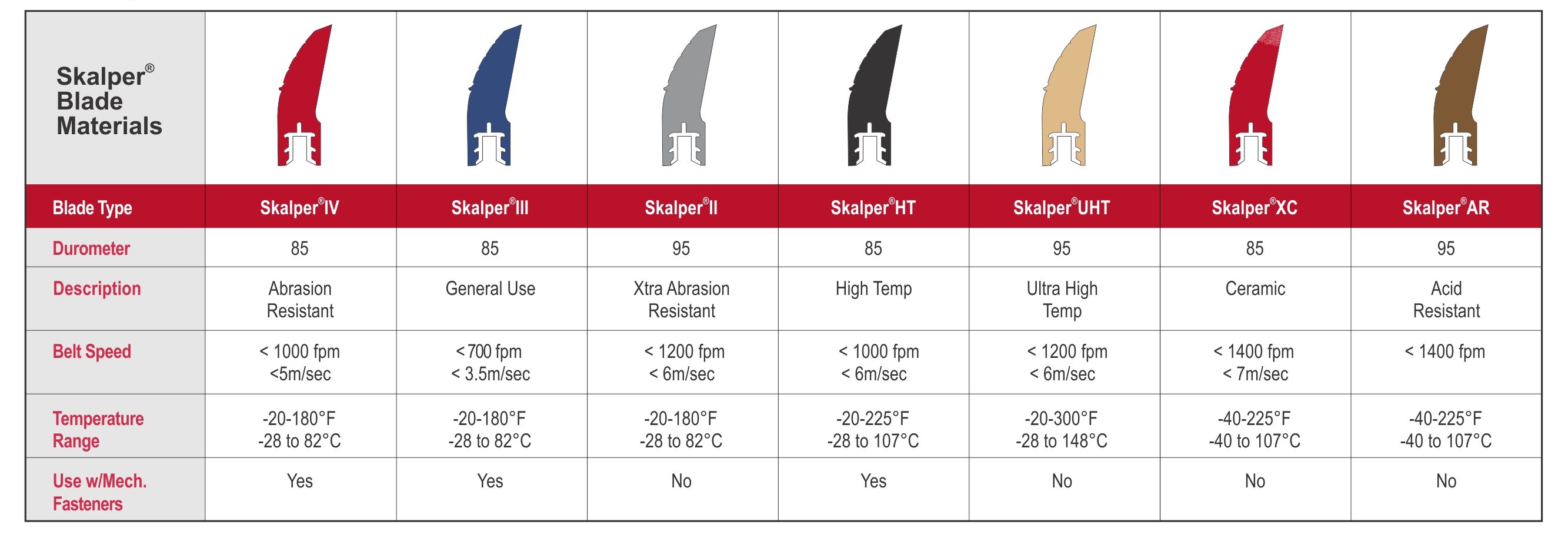

Skalper® Blade Options and Specifications

Part Numbers

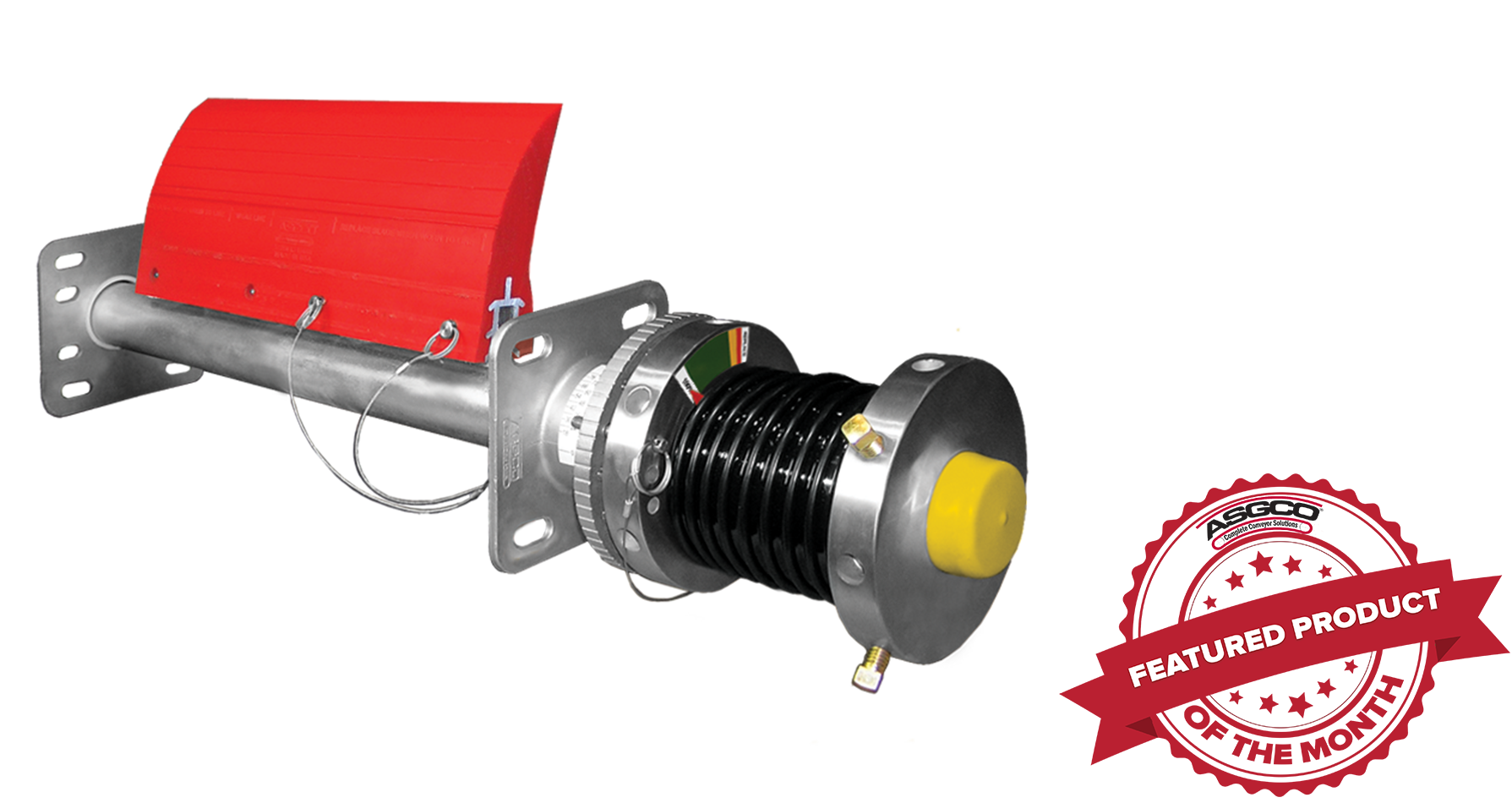

Skalper® Systems with E-Z Torque® Tensioner

Skalper Systems with all necessary mounting components in one economical package. Each System includes: one (1) Skalper Blade,(1) Transverse Mounting Element,(1) Mounting Assembly Kit,(1) E-Z Torque Tensioner. ** Please specify SK 2, SK 4, HT, UHT when ordering.

| Part Number | Belt Width in. | Belt Width mm. | Blade Width in. | Blade Width mm. | Weight lbs |

|---|---|---|---|---|---|

| M-SK*-SYS-18-EZT-2 | 18 | 450 | 18 | 450 | 61 |

| M-SK*-SYS-24-EZT-2 | 24 | 600 | 24 | 600 | 68 |

| M-SK*-SYS-30-EZT-2 | 30 | 750 | 30 | 750 | 75 |

| M-SK*-SYS-36-EZT-2 | 36 | 900 | 36 | 900 | 82 |

| M-SK*-SYS-42-EZT-2 | 42 | 1050 | 42 | 1050 | 87 |

| M-SK*-SYS-48-EZT-2 | 48 | 1200 | 48 | 1200 | 96 |

| M-SK*-SYS-54-EZT-2 | 54 | 1350 | 54 | 1350 | 103 |

| M-SK*-SYS-60-EZT-2 | 60 | 1500 | 60 | 1500 | 110 |

| M-SK*-SYS-72-EZT-2 | 72 | 1800 | 72 | 1800 | 124 |

| M-SK*-SYS-84-EZT-2 | 84 | 2100 | 84 | 2100 | 138 |

Part Numbers

Skalper® Systems with E-Z Torque® Tensioner (BW-6)

Skalper® Systems with all necessary mounting components in one economical package. Each System includes: one (1) Skalper® Blade, (1) Transverse Mounting Element, (1) Mounting Assembly Kit,(1) E-Z Torque® Tensioner. ** Please specify SK 2, SK 4, HT, UHT when ordering

| Part Number | Belt Width in. | Belt Width mm. | Blade Width in. | Blade Width mm. | Weight lbs |

|---|---|---|---|---|---|

| M-SK*-SYS-18-EZT-12-2 | 18 | 450 | 12 | 300 | 59 |

| M-SK*-SYS-24-EZT-18-2 | 24 | 600 | 18 | 450 | 66 |

| M-SK*-SYS-30-EZT-24-2 | 30 | 750 | 24 | 600 | 73 |

| M-SK*-SYS-36-EZT-30-2 | 36 | 900 | 30 | 750 | 80 |

| M-SK*-SYS-42-EZT-36-2 | 42 | 1200 | 421 | 1050 | 94 |

| M-SK*-SYS-48-EZT-42-2 | 48 | 1200 | 42 | 1050 | 94 |

| M-SK*-SYS-54-EZT-48-2 | 54 | 1350 | 48 | 1200 | 101 |

| M-SK*-SYS-60-EZT-54-2 | 60 | 1500 | 54 | 1350 | 108 |

| M-SK*-SYS-72-EZT-66-2 | 72 | 1800 | 66 | 1650 | 122 |

| M-SK*-SYS-84-EZT-78-2 | 84 | 2100 | 78 | 1950 | 136 |

Part Numbers

Skalper® Systems with E-Z Torque® Tensioner (BW-12)

Skalper® Systems with all necessary mounting components in one economical package. Each System includes: one (1) Skalper® Blade, (1) Transverse Mounting Element, (1) Mounting Assembly Kit,(1) E-Z Torque® Tensioner. ** Please specify SK 2, SK 4, HT, UHT when ordering

| Part Number | BELT WIDTH IN. | BELT WIDTH MM. | BLADE WIDTH IN. | BLADE WIDTH MM. | WEIGHT LBS |

|---|---|---|---|---|---|

| M-SK*-SYS-36-EZT-24-2 | 36 | 900 | 24 | 600 | 80 |

| M-SK*-SYS-42-EZT-30-2 | 42 | 1060 | 30 | 760 | 85 |

| M-SK*-SYS-48-EZT-36-2 | 48 | 1200 | 36 | 900 | 94 |

| M-SK*-SYS-54-EZT-42-2 | 54 | 1350 | 42 | 1060 | 122 |

| M-SK*-SYS-60-EZT-48-2 | 60 | 1500 | 48 | 1200 | 108 |

| M-SK*-SYS-72-EZT-60-2 | 72 | 1800 | 60 | 1500 | 122 |

| M-SK*-SYS-84-EZT-72-2 | 84 | 2100 | 72 | 1800 | 136 |

Literature Downloads

Solutions Case Studies

ASGCO Skalper® Belt Cleaners Reduce Carry-Back and Dust at Mid-Western…

Read More >

Objective: Eliminate carry-back, reduce housekeeping, minimize safety issues, reduce maintenance…

Read More >

Objective: To remove the sticky carry-back and prevent it from…

Read More >