Standard Duty Primary Belt Cleaning System

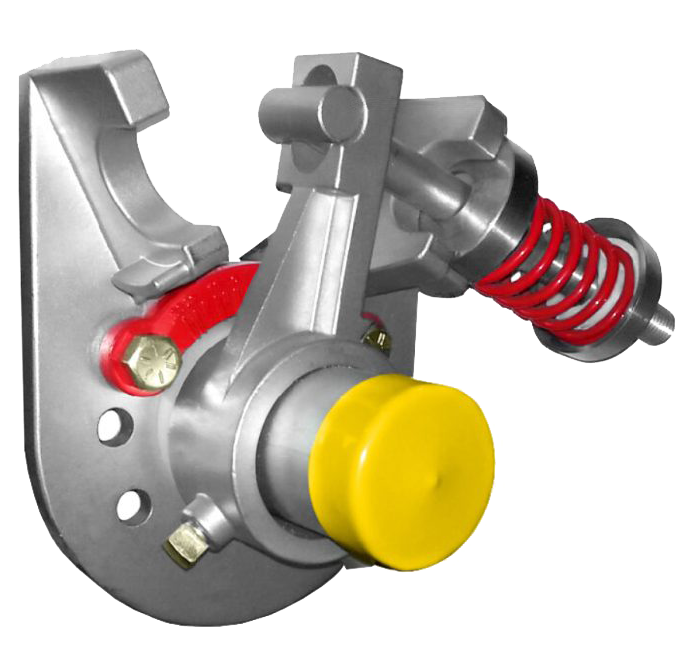

Design Features

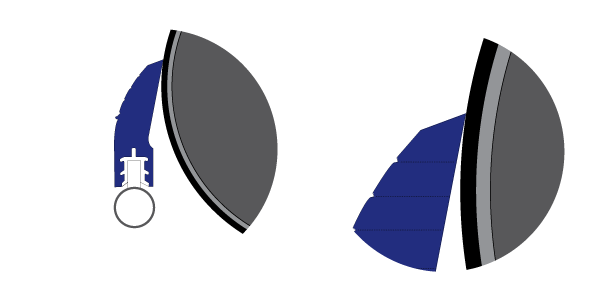

- Excellent Performance – of our patented Skalper® blade design maintains an effective cleaning edge throughout the life of the blade and can be changed for the optimum in blade coverage across the belt’s material carry path for better cleaning efficiency

- Quick Change Blade – stainless steel pin blade change-out system is a one-minute, no-tool operation.

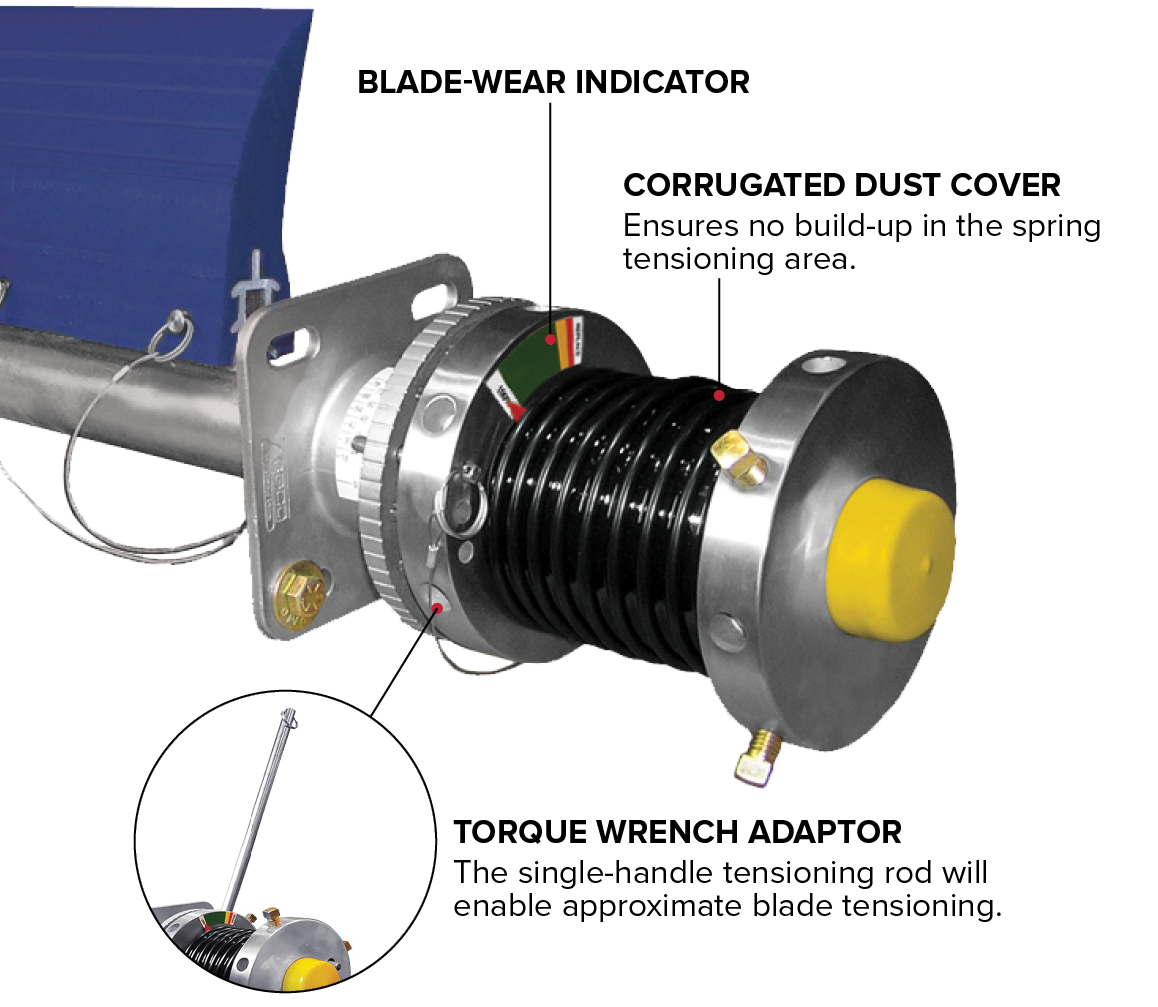

- Torque Spring – provides a greateer degree of tensioning per inchof blade verses compression springs which require more tensioning adjustment for the life of the blade.

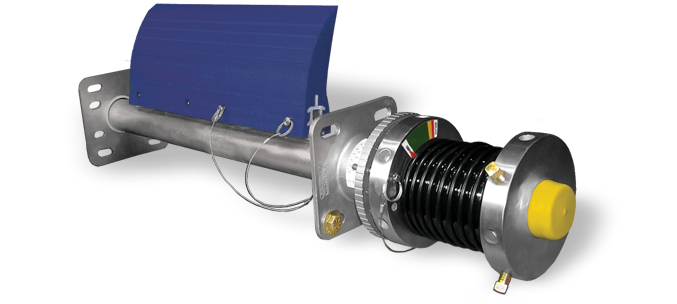

- Available with Force-1™ Tensioner – (lifetime warranty) all stainless steel tensioner provides the effective tension to the Skalper® blade as it self-adjusts and can be easily reset to optimal blade tension.

- 100% Lifetime Warranty on Tensioner

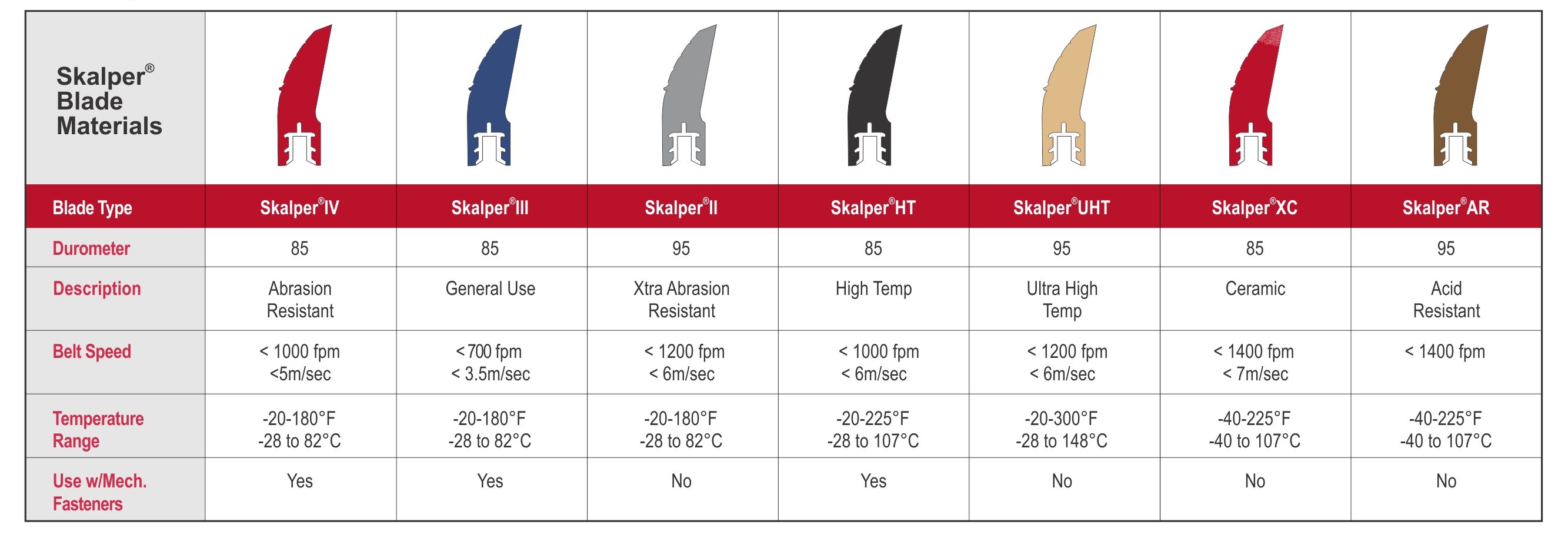

Skalper® Blade Options and Specifications

Part Numbers

Skalper III® with E-Z Torque® Tensioner (Full Belt Width)

| Part Number | Belt Width in. | Belt Width mm. | Blade Width in. | Blade Width mm. | Weight lbs |

|---|---|---|---|---|---|

| M-SBB-SYS-18-EZT-2 | 18 | 450 | 18 | 450 | 66 |

| M-SBB-SYS-24-EZT-2 | 24 | 600 | 24 | 600 | 72 |

| M-SBB-SYS-30-EZT-2 | 30 | 750 | 30 | 750 | 79 |

| M-SBB-SYS-36-EZT-2 | 36 | 900 | 36 | 900 | 85 |

| M-SBB-SYS-42-EZT-2 | 42 | 1500 | 42 | 1500 | 92 |

| M-SBB-SYS-48-EZT-2 | 48 | 1200 | 48 | 1200 | 98 |

| M-SBB-SYS-54-EZT-2 | 54 | 1350 | 54 | 1350 | 105 |

| M-SBB-SYS-60-EZT-2 | 60 | 1500 | 60 | 1500 | 112 |

| M-SBB-SYS-72-EZT-2 | 72 | 1800 | 72 | 1800 | 144 |

| M-SBB-SYS-84-EZT-2 | 84 | 2100 | 84 | 2100 | 160 |

Part Numbers

Skalper III® with E-Z Torque® Tensioner (BW-6)

| Part Number | Belt Width in. | Belt Width mm. | Blade Width in. | Blade Width mm. | Weight lbs |

|---|---|---|---|---|---|

| M-SBB-SYS-18-EZT-12-2 | 18 | 450 | 12 | 300 | 63 |

| M-SBB-SYS-24-EZT-18-2 | 24 | 600 | 18 | 450 | 70 |

| M-SBB-SYS-30-EZT-24-2 | 30 | 750 | 24 | 600 | 76 |

| M-SBB-SYS-36-EZT-30-2 | 36 | 900 | 30 | 750 | 83 |

| M-SBB-SYS-42-EZT-36-2 | 42 | 1500 | 36 | 900 | 89 |

| M-SBB-SYS-48-EZT-42-2 | 48 | 1200 | 42 | 1050 | 96 |

| M-SBB-SYS-54-EZT-48-2 | 54 | 1350 | 48 | 1200 | 102 |

| M-SBB-SYS-60-EZT-54-2 | 60 | 1500 | 54 | 1350 | 109 |

| M-SBB-SYS-72-EZT-66-2 | 72 | 1800 | 66 | 1650 | 141 |

| M-SBB-SYS-84-EZT-78-2 | 84 | 2100 | 78 | 1950 | 157 |

Part Numbers

Skalper III® with Force-1™ Tensioner

| Part Number | Belt Width in. | Belt Width mm. | Blade Width in. | Blade Width mm. | Weight lbs |

|---|---|---|---|---|---|

| M-SBB-SYS-18-DS-1 | 18 | 450 | 18 | 450 | 50 |

| M-SBB-SYS-24-DS-1 | 24 | 600 | 24 | 600 | 57 |

| M-SBB-SYS-30-DS-1 | 30 | 750 | 30 | 750 | 64 |

| M-SBB-SYS-36-DS-1 | 36 | 900 | 36 | 900 | 71 |

| M-SBB-SYS-42-DS-1 | 42 | 1500 | 42 | 1500 | 78 |

| M-SBB-SYS-48-DS-1 | 48 | 1200 | 48 | 1200 | 85 |

| M-SBB-SYS-54-DS-1 | 54 | 1350 | 54 | 1350 | 92 |

| M-SBB-SYS-60-DS-1 | 60 | 1500 | 60 | 1500 | 99 |

| M-SBB-SYS-66-DS-1 | 66 | 1650 | 66 | 1650 | 106 |

| M-SBB-SYS-72-DS-1 | 72 | 1800 | 72 | 1800 | 113 |

| M-SBB-SYS-84-DS-1 | 84 | 2100 | 84 | 2100 | 120 |

Part Numbers

Skalper III® Systems with Force-1™ Tensioner (BW-6)

| Part Number | Belt Width in. | Belt Width mm. | Blade Width in. | Blade Width mm. | Weight lbs |

|---|---|---|---|---|---|

| M-SBB-SYS-18-DS-12-1 | 18 | 450 | 12 | 300 | 48 |

| M-SBB-SYS-24-DS-18-1 | 24 | 600 | 18 | 450 | 54 |

| M-SBB-SYS-30-DS-24-1 | 30 | 750 | 24 | 600 | 60 |

| M-SBB-SYS-36-DS-30-1 | 36 | 900 | 30 | 750 | 66 |

| M-SBB-SYS-42-DS-36-1 | 42 | 1500 | 36 | 900 | 73 |

| M-SBB-SYS-48-DS-42-1 | 48 | 1200 | 42 | 1050 | 79 |

| M-SBB-SYS-54-DS-48-1 | 54 | 1350 | 48 | 1200 | 85 |

| M-SBB-SYS-60-DS-54-1 | 60 | 1500 | 54 | 1350 | 92 |

| M-SBB-SYS-66-DS-60-1 | 66 | 1650 | 60 | 1500 | 105 |

| M-SBB-SYS-72-DS-66-1 | 72 | 1800 | 66 | 1650 | 121 |

| M-SBB-SYS-84-DS-78-1 | 84 | 2100 | 78 | 1950 | 137 |

Available with Force-1™ Tensioner

Available with Force-1™ Tensioner