Objective: To prevent chute pluggage and pre-mature wear while creating a flow within the chute and onto the belt.

Challenge: The existing round chutes were hard to align. The chutes had to penetrate two (2) different levels, each with existing openings and be able to line up so the material could flow without interference. The incredibly heavy, thick and pasty material made it nearly impossible to convey and to flow through the chutes, causing continuous outages and downtime for maintenance.

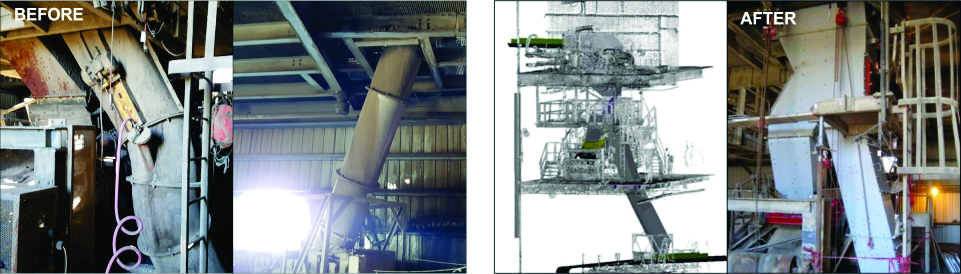

Solution: ASGCO® technicians thoroughly inspected the failing system and proposed a redesign of the existing transfer chute using our 3-DEM® Transfer Point Simulation software and advanced Flo-Control® chute fabrication. With our Point Cloud Laser Scanning technology we can create realistic models using pinpoint accuracy to locate any obstructions and to hit the 2 existing openings on two different levels without any interference. Once the chute and conveyor are modeled the image is overlaid into the cloud point scan to ensure there are no interferences and that all modeled equipment fits properly. A combination of liners inside the chute would provide optimum sliding surface for the material handling.

Results: The new transfer point has been a big improvement. The existing chute used to plug up several times a shift due to constant plugging. They would have to shut everything down and send workers to shovel and wash it out to open it up again. After the installation of the new chute, the maintenance and downtime has been reduced by 85%!