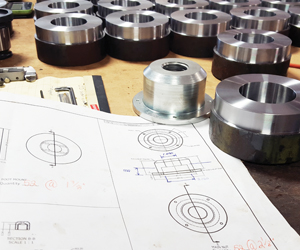

The ASGCO® Steel Fabrication Division boasts 30,000 square feet of in-house Metal Fabrication and Machining. This workspace allows us to provide custom quality-controlled components and assemblies that support the requirements of machine builds as well as enables us to deliver a fast turn-around time. We have extensive CNC plasma and laser cutting equipment, machining equipment, including CAD/CAM machinery for CNC milling, drilling, turning, and grinding operations on all types of metal and plastic materials. Our specialties lie in CNC horizontal turning, vertical 5-axis milling, horizontal milling, and high-speed machining. With those particular capabilities, we are able to precision machine parts from 1″ to 120″.

Our metal fabrication engineering and machining teams know their trades and value quality, accuracy, and on-time completion of their work. Both teams work together to manufacture components integral to ASGCO’s custom design build and build-to-print equipment, as well as provide job-shop CNC machining and fabrication services for clients. ASGCO’s in-house abilities demonstrate our full-service commitment to clients and ensure exceptional quality control of our manufactured components. Whether you need help with computer automated design, aluminum welding, metal spraying, vibratory finishing, or welding repair—get in touch with us today. We offer the best metal fab services.