Feeders

Syntron® Vibrating Feeders for heavy industry are ideal for feeding a wide variety of bulk materials from storage piles, hoppers, bins and silos. Rugged and dependable, Syntron® heavy-duty feeders are backed by years of service with proven performance in the mining, aggregates, glass, cement, chemical, wood products and steel industries.

HEAVY DUTY FEEDERS DESIGNED TO INCREASE BULK

HANDLING PRODUCTIVITY WITH HIGH FEED RATES.

SYNTRON® HEAVY-DUTY ELECTROMAGNETIC FEEDERS

Syntron® Heavy-Duty Electromagnetic Feeders are the most recognized name in the industry. With models having capacities ranging from 25 to 1,600 tons per hour, these feeders are capable of handling a variety of materials from fine powder to large, coarse particles.

Performance Feeder Features:

- Dust-tight and maintenance-free drive units: Feeders have no mechanical parts to wear out, such as cams, eccentrics, belts and bearings – thus eliminating the need for lubrication.

- Stroke generated by the electromagnetic field produced by the coil.

- High Frequency: 3600 VPM at 60 Hz or 50 Hz with EVF Control for maximum feed rate.

- Stroke – .080 inches: New “HP” units operate at .080″ at 3600 VPM to provide 40% more output than traditional units at . 060″

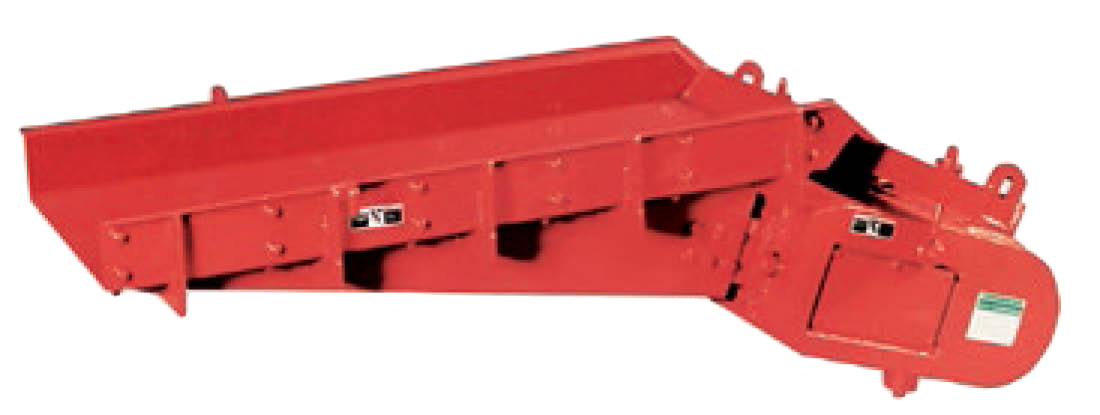

SYNTRON® HEAVY-DUTY ELECTROMECHANICAL FEEDERS

The High Capacity Performers

Syntron® MF Heavy-Duty Electromechanical Feeders are the heavyweights of bulk material handling and are used for higher capacity requirements. The ten heavy-duty models handle capacities from 600 to 4,000 tons per hour.*

Syntron® Heavy-Duty Electromechanical Feeders combine extra structural strength with durable components. The deep wing plates form a bridge between the inlet and discharge suspension supports, providing extra strength for years of dependable service.

Performance Feeder Features:

• Operating frequency – 1100 VPM at 55.4 Hz

• Stroke: 0.25 – 0.30 inches

• Start and operate fully loaded or empty

• Dependable, flexible, easily adjustable

• Minimal component design to reduce adjustments and

replacements due to wear loaded or empty