Conveyor Pulleys

Martin manufactures heavy duty conveyor pulleys, including drum pulleys, wing pulleys, turbine pulleys, engineered pulleys, and special construction pulleys.

Martin’s product line meets the demanding requirements of industries such as: sand and gravel quarries, coal mines, unit packaging, food processing, and recycling. These pulleys are manufactured to the same quality standards you have come to expect from Martin.

COMPLETE LINE OF CONVEYOR PULLEYS TO MEET THE DEMANDS OF YOUR APPLICATIONS.

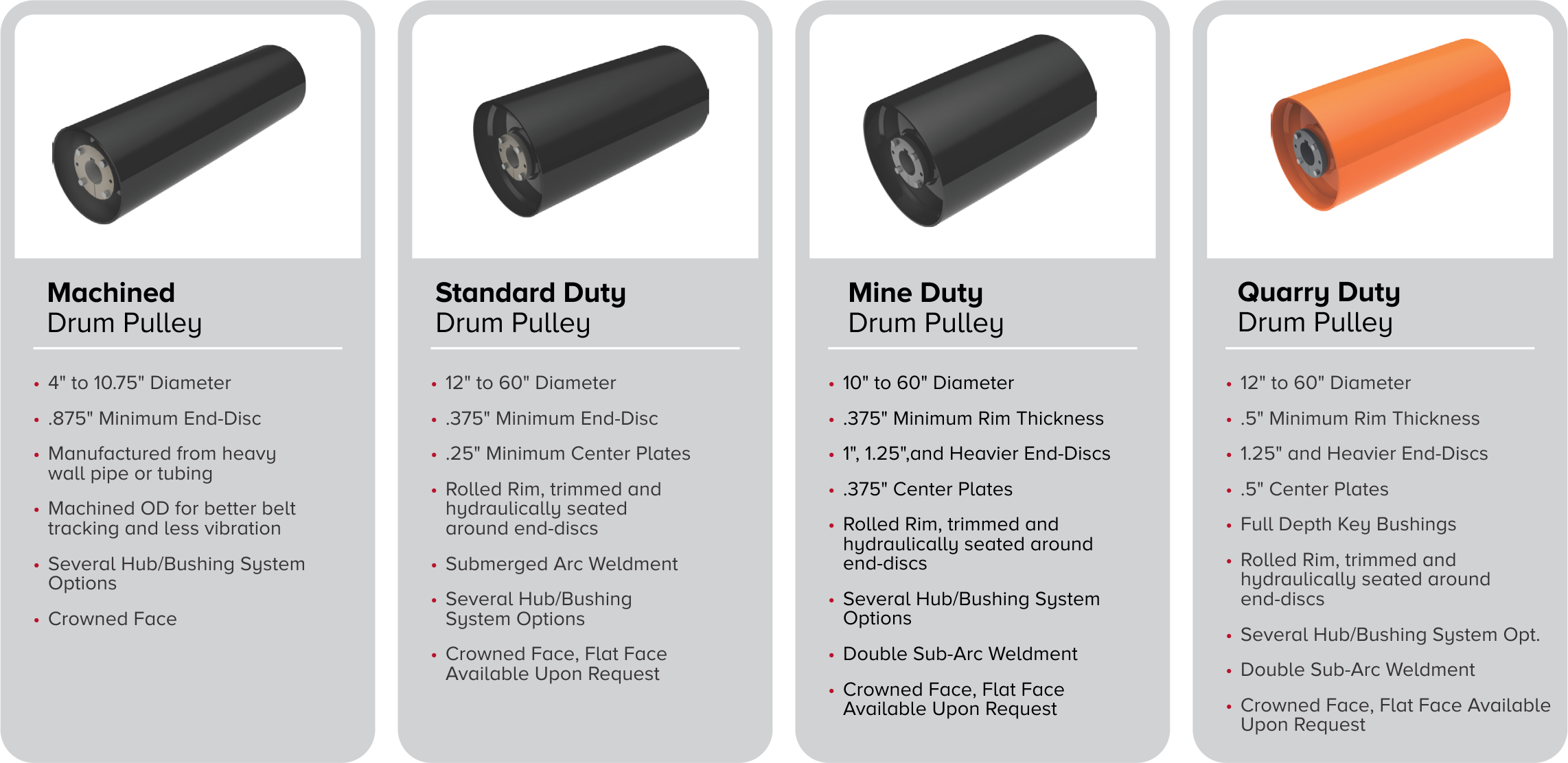

DRUM PULLEYS

Martin Drum pulleys are manufactured from thick wall pipe or tubing,

with a crowned face or flat face. Martin has standard duty, quarry

duty, mine duty and machined drum pulleys.

• Machine Drum Pulleys

• Standard Duty Drum Pulleys

• Mine Duty Drum Pulleys

• Quarry Duty Drum Pulleys

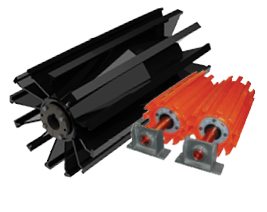

WING PULLEYS

Martin Wing Pulleys are constructed from extremely heavy materials and

are recognized in the industry as the most aggressive CEMA grade stock

pulley on the shelf.

- Standard Duty Wing Pulleys

- Mine Duty Wing Pulleys

- Quarry Duty “AR” Wing Pulleys

- Special Construction Pulleys

CFW WING PULLEYS

Martin’s Clean Flight Wing Pulley is a much stronger design, constructed with distinctly aggressive materials and thick flight.

- Enhanced Belt Tracking

- Decreased Vibration

- Reduced Noise

- Improved Material Rejection

- No Contact Bar

- Maximum Cleaning Efficiency

HEAVY-DUTY CONVEYING PULLEYS

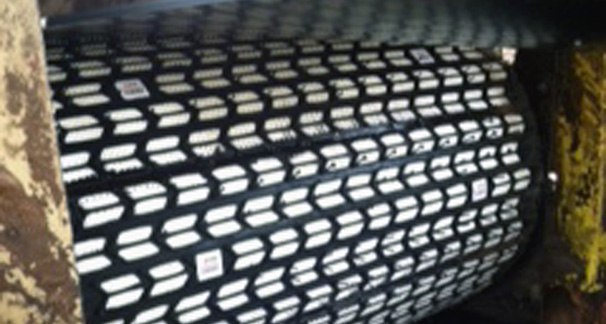

Martin’s Lagging is designed to meet the demands of your application. We o er Ceramic Lagging custom fit to your application, vulcanized rubber, cold bond lagging, and strip lagging. Other lagging compounds such as Urethane, EPDM White Food Grade FDA approved rubber, SOF (static conductive/oil resistant/flame resistant), and many other lagging products are also available.

- Vulcanized Rubber Lagging

- Ceramic Lagging

- VC-Lagg (Vulcanized Ceramic Lagging)

- Take-up Frames

- Bearings & Bushings

- Custom Shafting

DODGE WING PULLEYS ARE DESIGNED TO OPERATE IN THE TOUGHEST CONDITIONS.

Drum Pulleys

Dodge Heavy Duty and Mine Duty Extra (MDX) drum pulleys deliver high performance and are available when you need them. Available from stock in many common sizes, or custom made, Dodge Heavy Duty drum pulleys meet and/or exceed CEMA (Conveyor Equipment Manufacturers Association) application standards for use with conveyor belts rated up to 750 PIW (Pounds per Inch of Belt Width) / 131 kN/m.

Feature

Heavy-duty one-piece rim construction with submerged arc weldments. Multiple shaft attachment options available (HE, XT, QD or Taper-Lock). Available from stock with taper-compression hubs and a variety of lagging options including standard stock SBR rubber, D-LAG natural rubber, and made-to-order vulcanized ceramic lagging.

Industries

- Aggregate & Cement

- Mining

- Paper & Forest

- Power Generation

- Unit & Baggage Handling

Applications

Bulk handling conveyors for:

- head

- drive

- snub

- bend

- take-up

- tail

- discharge pulley

Wing Pulleys

Dodge Heavy Duty and Mine Duty wing pulleys deliver high performance and are available when you need them. Available from stock in many common sizes, or custom made, Dodge wing pulleys meet and/or exceed CEMA (Conveyor Equipment Manufacturers Association) application standards for use with conveyor belts rated up to 450 PIW (Pounds per Inch of Belt Width) / 78 kN/m.

Feature

Heavy-duty wing pulleys designed with minimum 1/4″ x 1-1/2″ contact bars and patent-pending Spider wing support to minimize wing folding. Available from stock with HE hubs. Also available with urethane WING-LAG for outstanding performance in abrasive conditions.

Mine Duty wing pulleys designed with minimum 5/8″ x 1-1/2″ contact bars and patent-pending Spider wing support to minimize wing folding. Available from stock with HE hubs.

Mine Duty Extra (MDX) wing pulleys designed with minimum 3/4″ x 2″ contact bars for ultimate protection from wing damage. Maximum 5″ wing height minimizes the possibility of wing folding.

Industries

- Aggregate & Cement

- Mining

- Paper & Forest

- Power Generation

- Unit & Baggage Handling

Applications

Bulk handling conveyors for the bend, take-up, and tail pulley.

Elevator Pulleys

Dodge elevator drum pulleys utilize submerged arc welds and one-piece rims to provide exceptional durability. Offering HE, XT, QD, or Taper-Lock hubs and a variety of vulcanized and weld-on lagging options, Dodge elevator pulleys are custom built to last.

Feature

Lagging options include Holz SOF, SBR rubber, abrasive resistant D-LAG, and the Dodge exclusive FOS, which is a vulcanized fire, oil and static resistant lagging material. Both Holz SOF and Dodge FOS lagging are static conducive to less than 1 x 10^6 ohm.

Bushing systems available include HE bushings, the toughest tapered bushing system available with larger bolts and more bolts versus competitive bushings. Also available are XT, QD and Taper-Lock bushings.

Industries

- Agriculture

- Power Generation

- Aggregate & Cement

Applications

- Bucket elevator head and boot pulleys.

COMBINING THE BEST OF MODERN ENGINEERING PRACTICES WITH REDEFINED MANUFACTURING TECHNIQUES.

SUPERIOR DRUM PULLEYS

Drum pulleys are one of the most versatile components of a conveyor system. Depending on their specifications, they can serve in a variety of roles or positions, including drive or head, return or tail, bend tensioning, snub tensioning and/or take-up pulleys, which increase or decrease the amount of slack in your conveyor belt.

Maximum pulley life is essential to cost-efficient material handling and high-capacity production. Importantly, a manufacturer’s approach to pulley design, manufacturing and proper application has a direct effect upon pulley reliability or potential pulley failure.

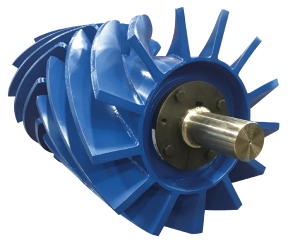

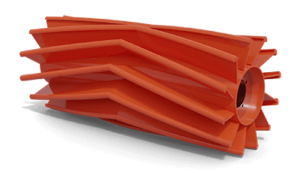

SUPERIOR WING PULLEYS

Before Superior’s Chevron® Pulley, traditional wing pulley designs were notorious for trapping rocks, gathering fugitive material and bending prematurely. The rocks punctured conveyor belts and the folded or filled wings caused belting to mistrack.

V-shaped Chevron Wing Pulleys reject and repel any incoming fugitive material, which significantly extends the operating life of your conveyor and many of its components.

It’s the one that started a tail pulley revolution back in 2007. That’s when Superior was first to introduce the v-shaped wing pulley and quickly after, the Chevron Pulley became the standard for conveyor wing pulleys.

Feature and Benefits

- Deflects material, which prevents fugitive entrapment and extends service life.

Steady contact between pulley and belt reduces noise and vibration caused by beating action. - A curved wing cap is less damaging to the belt and easier on mechanical splices.

- Designed without a center plate, which can cut the belt and linked wings eliminates a catch point.

- AR steel option extends service life in harshest applications.