Conveyor Idlers

ASGCO® has a vast selection of idlers, designed and built for the toughest jobs, that set the standard of ex cellence for bulk material handling. Our full line of conveyor idler (rollers) products, meet or ex ceed CEMA C, D, E specifications. We represent the highest quality idlers to assist our customers in helping make their plant/mine/facility to become more efficient, safe and productive.

ROBUST IDLER FRAME CONSTRUCTION AND SEALED-FOR LIFE IDLERS FOR THE TOUGHEST BELT CONVEYOR APPLICATIONS.

TOUGH CONSTRUCTION FOR TOUGH APPLICATIONS.

Martin manufactures heavy-duty Idlers and components that exceed CEMA standards. Heavy-duty construction and triple labyrinth seals allow for trouble-free part life in the harshest of applications. With Idlers available when and where you need them, Martin can provide the complete solution for your belt conveyor needs. Martin Idlers are stocked in a wide range of belt widths to meet customers’ needs.

IN STOCK NOW FOR IMMEDIATE DELIVERY.

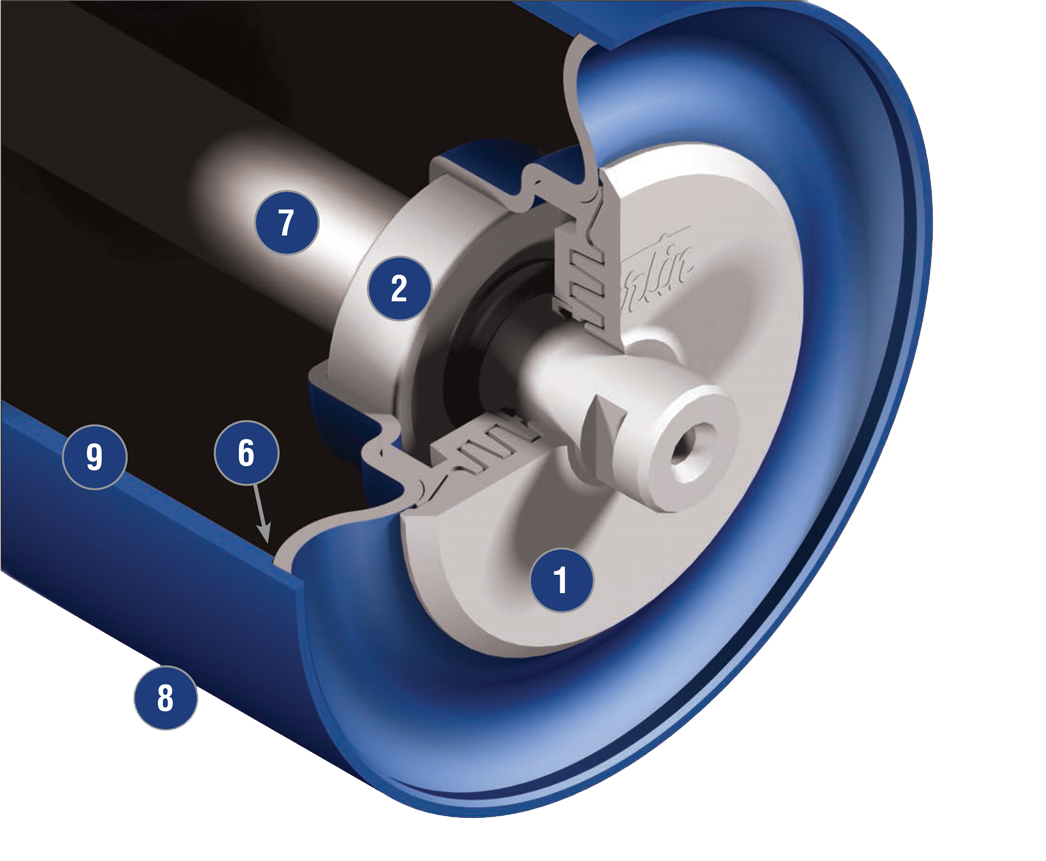

- Martin Triple Labyrinth Seal

- Sealed for life ball bearings

- Extremely low rolling resistance

- CEMA C & D standard product line

- Roll gap meets NIBA recommendation

- Idler end welding

- Solid steel shaft

- 9 gauge steel shell/cover

RELIABILITY STARTS WITH A GREAT PRODUCT

- CEMA C, D and E Idlers

- Sealed for life ball bearings

- Triple Labyrinth Seal

- Product line offering of 18″- 96″ belt widths

- Extremely low rolling resistance = lowest operator cost

- Drop-In replacement rolls for all major competitors

- 9 gauge tubing for CEMA C & D and 7 gauge tubing for CEMA E

MARTIN SEAL GUARD DESIGN

- External Shield deters impurities from entering the bearing housing

- Flinger Design removes contaminates away from the bearing housing by centrifugal force

- Martin Triple Labyrinth Seal design is grease filled and offers an additional level ofprotection from contaminants impacting the bearing CEMA C, D and E Idlers have sealed for life ball bearings

WE OFFER A FULL LINE OF (CONVEYOR IDLER ROLLERS) PRODUCTS THAT MAXIMIZE UP-TIME AND PRODUCTIVITY

LINK-BELT® CONVEYOR IDLERS

For over 130 years, Syntron Material Handling and the Link -Belt® Company have designed and manufactured belt conveyor parts including conveyor idlers (rollers) and components that set the standard of excellence for bulk material handling throughout the world. Quality products, prompt shipment, and after-sales service are Syntron Material Handling trademarks.

We offer a full line of conveyor idlers (rollers) products, ranging from 14″ to 120″ in belt widths, that meet or exceed CEMA B, C, D, E, and F specifications.

By combining the strengths, capabilities, and expertise we are able to offer the broadest selection of material handling solutions available anywhere. Our brands, Syntron and Link-Belt, are recognized around the world for their history of exceptional performance and value in material handling and vibratory feeding equipment.

All Syntron® idlers conform to OSHA operational safety standards.

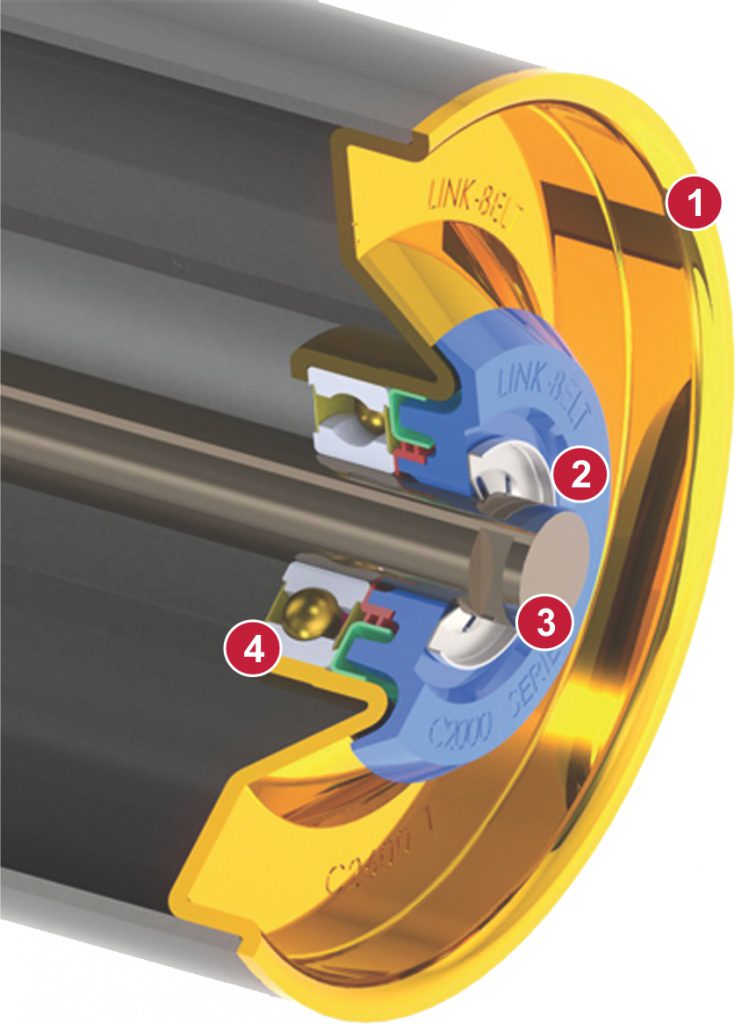

- Precision formed Pressed Head

- Impact/corrosion resistant Deflector

- High strength, Solid Shaft

- Deep Groove Bearings

NEW BALL BEARING IDLERS

- Interchangeable idler assemblies

- Maintenance-free sealed ball bearings

- Custom powder coating

- Value priced with CEMA C performance ratings

LINK-BELT FEATURES INCLUDE:

- Types and size that meet or exceed CEMA B, C, D, E and F series requirements for capacity belt width and condition of service

- Retrofit availability

- Advanced sealing system

- Double sealed, ball bearing designs as well as precision tapered roller bearings

- ES Series (Extreme Service) idlers for Canadian Oil Sands

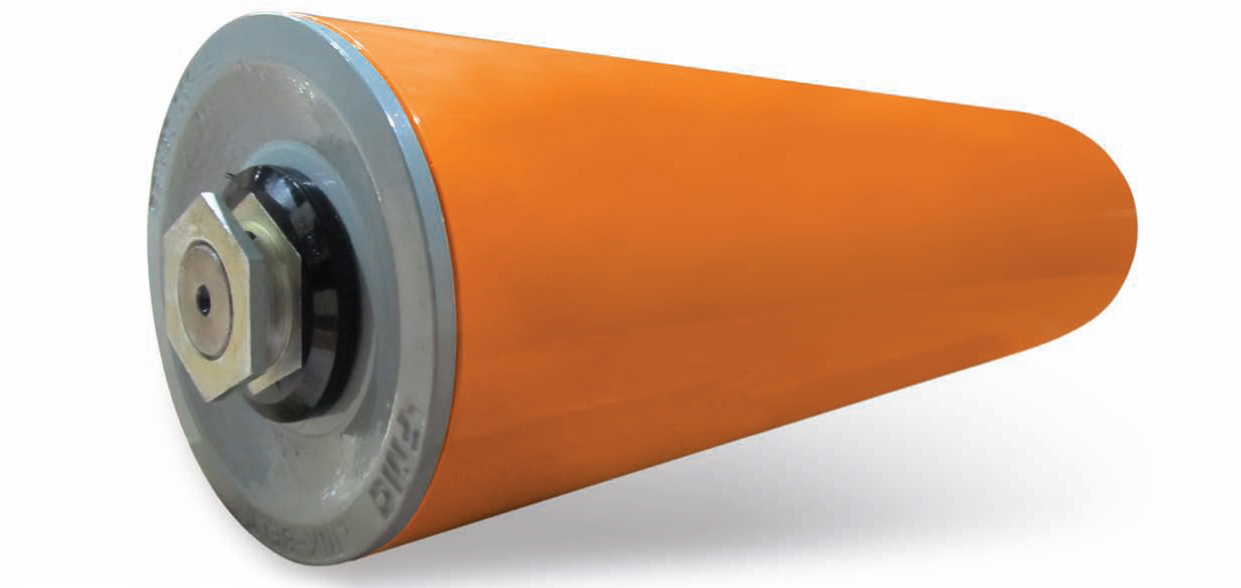

COMPOSITE IDLER ROLLS

- Excellent strength

- Lighter weight

- Superior toughness

- High corrosion resistance

- High abrasion resistance

- Reduced material build-up

- Low coefficient of thermal expansion

- Environmentally Friendly

SYNTRON MH CONVEYOR SERIES

- Series B2000 Idlers

- Series C2000 Idlers

- Series C3000 & D3000

- Series E4000 Idlers

- Series F5000 Idlers

- Composite Rolls

- Side Guide Idlers

- Impact Sliders

- Truss Frame Idlers

WE OFFER A LARGE SELECTION OF FLEXIBLE PRODUCT DESIGNS IN OUR CEMA RATED CONVEYOR IDLER LINEUP.

SUPERIOR® CONVEYOR IDLERS

Superior first entered the idler market in 1974, becoming one of the few equipment manufacturers that also supplies its own components. We are constantly engaged in research and development to craft the best idlers to fit the hundreds of conveyors that we sell each year, coming up with better designs to reject fugitive material and protect idler bearings.

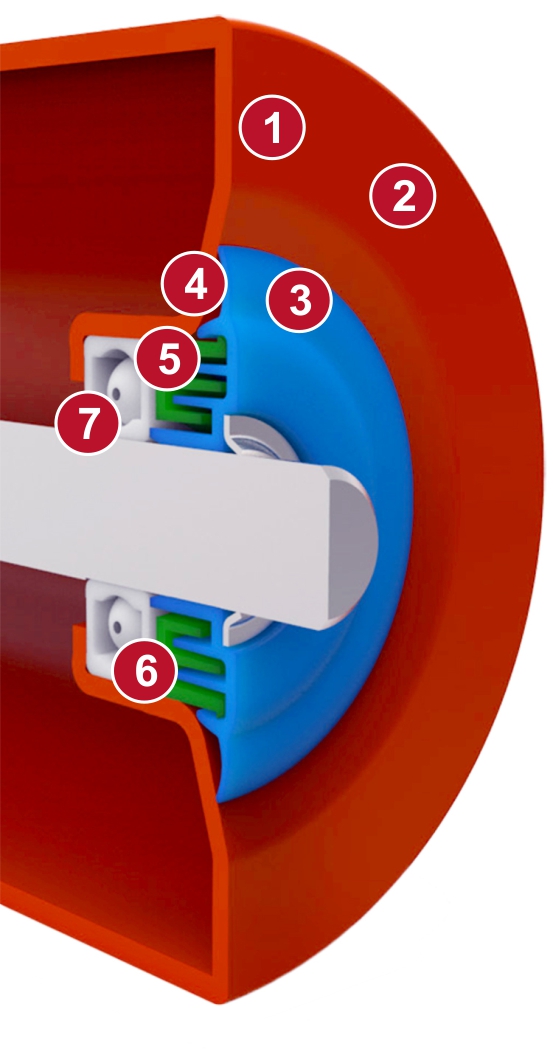

- End Disc

- Flat Surface

- Stationary External Seal

- Centrifugal Force Chamber

- Contact Seal

- Triple Labyrinth Seal

- Ball Bearing

SPINGUARD® SEAL TECHNOLOGY

- Contact seal prevents material from entering seal cavity

- Grease-filled triple labyrinth seal shuts out contaminants

- Stationary external seal prevents material pinch points

QUICK REACTION

- Distributors stocked with standard products

- One to two day turnarounds on custom designs

HIGH QUALITY CONSTRUCTION

- Thick or thicker steel construction compared to other brands

- Two year complete components warranty

- Largest, broadest range of all CEMA categories on the market

ECONOMICAL RETROFIT ROLLS

- Slotted shafts fit most competitor frames

- Hex nut adapter available for hex nut style brackets

NO MAINTENANCE BASE FRAME

- Angled base sheds material

- Flared, non-clogging center stands

- No material pinch points between roll and frame