Conveyor Chute Lining

ASGCO’s Chute Linings and Skirt Liners are designed to be an integral part of a conveyor system. Our pre-engineered chute lining protects and cushions the chute from the material being handled; Skirt Liners prevents fugitive materials from escaping and damaging the conveyor loading areas. We can build, design, fabricate and install chutes, and also repair and re-align existing chutes.

ASGCO® wear liner products are the longest lasting, most cost effective in the industry.

We Build, Design, Fabricate, Repair, Realign & Install Chutes

Combining the right liner with the correct chute design improves overall system efficiency and maximizes material transfer, promoting efficient flow, dust suppression and reduced buildup inside the chute.

ASGCO® wear liner products are the longest lasting, most cost effective in the industry:

- Steel Liners – Armorite®, AR 400 Internal Liners, Stainless Steel and Nitronic 30

- Ceramic Liners – X-Wear™, X-Wear MDX™ and X-Wear™ Canoe Skirt Liners

- Urethane Liners – Wide array of urethane products depending upon the application (Classifier Shoes, Hydrocyclone, etc.)

- Plastic Liners – UMHW, Nylon

- Nitronic SX – Stainless Steel

- Chromium Carbide

- Rubber Liners

Armorite™ Conveyor Skirt Liners, Chute Liners, Transfer Point & Wear Liners

Armorite Skirt Liners protect your skirtboard and provide a significantly longer wear life than currently used skirt liners. Armorite Wear Plates present a very cost effective method of extending wear life in chutes, hoppers, bins, impact walls and screen plates.

Armorite™ is an extremely hard, laminated bi-metalic, wear resistant composite, which has a normal hardness of 700 BHN (63Rc) produced by combining a highly alloyed chromium-molybdenum white iron (to AS 2027 15/3 Cr/Mo) and metallurgically bonding it to a mild thick steel backing plate. The resultant bond possesses high shear strength of over 250 Mpa and will not separate.

3-DEM and Flo-Control™ Conveyor Transfer Point Design, Fabrication & Installation for Improved Flo-Control

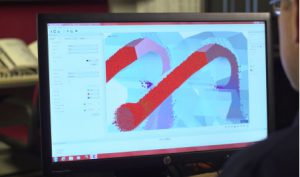

Transfer point design, fabrication and installations utilizing ASGCO’s 3-DEM chute analysis program (Discrete Element Methods) is a revolutionary way to handle granular and particulate material by streamlining the process from the point where material leaves the head pulley until it is deposited onto the receiving conveyor for a more deliberate control of the material as it flows from one conveyor to another. The performance of transfer chutes is an essential part to the productivity of the conveyor belt systems in the bulk solids industry.

These techniques are easily applied to both existing and new installations, resulting in significant cost improvements and system efficiencies. Combined with our conveyor and material handling knowledge, engineering capabilities and complete turn-key installation services, we are able to make transfer point problems a thing of the past.

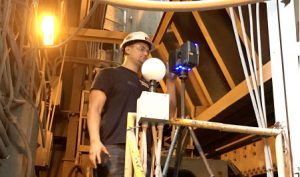

ASGCO® Point Cloud Laser Scanner is a powerful high-speed Focus3D X 130 HDR 3D scanner, delivering realistic and true-to-detail scan results.

The laser technology is more accurate than traditional methods because it looks at thousands of points along the clearance plane, not just a few sample points. The ultra-portable Point Cloud Laser Scanner enables fast, straightforward, and yet accurate measurements of facades, complex structures, production and supply facilities, accident sites, and large-volume components.

Ensures Accuracy

ASGCO® Point Cloud Laser Scanner delivers extraordinary color overlays for scanned point clouds. This improves the visualization of important details on site. Our system can capture over 1 million points per second and can scan through 360° horizontally and vertically.

Once the chute and conveyor are modeled the image is overlaid into the cloud point scan to ensure there are no interferences and that all modeled equipment fits properly.