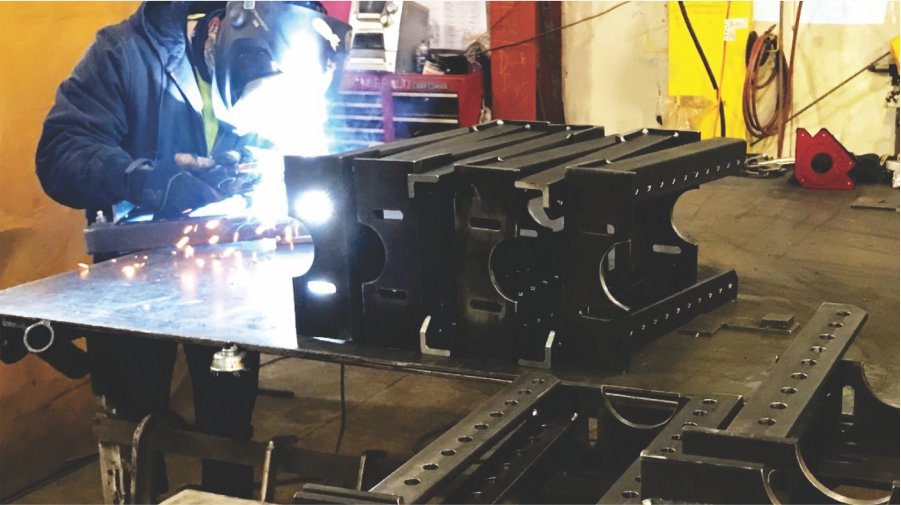

Fabrication & Welding

ASGCO®’s Steel Fabrication Division team of trained and highly-skilled welders are ready to meet the challenges of your project. Multiple welding stations combined with our experience in a wide variety of metals means ASGCO®’s Steel Fabrication Division can provide you with quality workmanship, on time, the first time.

Fabrication & Welding

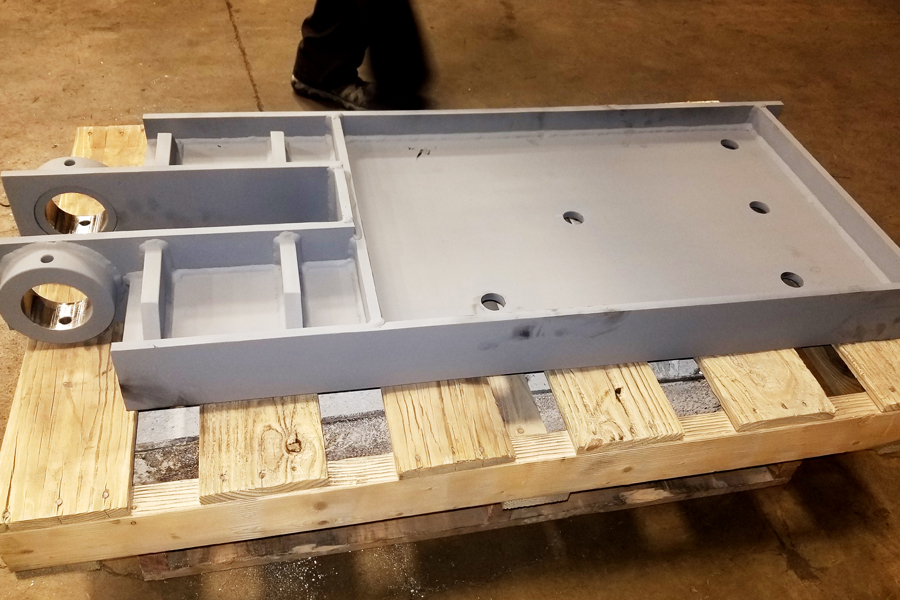

ASGCO’s Steel Fabrication Division experienced welders pride themselves on attention to detail. Our welders are certified and trained to meet both industry and our customers’ specifications.

Our capabilities can accommodate single-part projects or higher volume production runs, and we can handle a range of material thicknesses—from thin-gauge sheet metal to heavier structural plates.

Capabilities

- Mild Steel Plate welding using GMAW process

- Stainless Steel Plate welding using FCAW process

- Aluminum Plate welding GMAW and GTAW

- Pipe Welding GTAW, FCAW and GMAW

- Stud Welding capacity to 1”

- Complex Weldments

Material Types

- Steel

- Stainless Steel

- Aluminum