Benefits of a Conveyor

If you ever had a job where you had to carry heavy objects all day, you probably know about some of the benefits of a conveyor. You might have the back problems to prove it! Whether you’re moving minerals and rocks or boxes and food products, it takes a lot of time and effort for human workers to do this. The right conveyor belt can make the job a lot easier for your company. ASGCO is your one-stop-shop for all your conveyor needs. We’re here to help you find just the right solution for your company. After you read about the many benefits of moving materials with a conveyor, you can always get in contact with us for more information.

There are a Variety of Conveyor Solutions

Using a heavy-duty conveyor to haul rocks up a quarry is a little different than moving cookies or pretzels across a room for packaging. Some common conveyor types include belts, rollers, chains, chutes, buckets, and slats. You can acquire horizontal, inclined, or declined devices. Moreover, there are conveyors with turns, angles, and slopes built into them. You can even get a spiral conveyor. As your company continues to grow and develop, your needs may start to change. That’s okay. You can always adjust and add onto your current conveyor system. Or, you could install a brand new system that is even more energy efficient.

As a complete conveyor solutions company, ASGCO can provide any type of conveyor system that you need. Because the future of your company may be relying on your conveyor machine, it’s important to find just the right solution. The team at ASGCO can make this process much easier for you. Plus, we have technicians who install conveyors and replacement parts.

They are Very Useful

Any time you need a product moved, a conveyor makes the job much faster and easier for you. A heavy-duty conveyor can keep moving heavy, jagged objects in even harsh conditions. You can have peace of mind knowing that your manufacturing process won’t come to a halt. Plus, you won’t have to worry about logistics. Placing a product on a conveyor is a lot more simple than having one person separate the items. Then, someone has to carry the individual item and assemble it correctly. Then another person inspects it, packages it, stages it, and places it aside for shipping.

They Can Help Reduce Your Costs

When you have a conveyor in place, you won’t need as much labor, helping you save money in the long run. And conveyors do quick work, helping to cut back on your production hours. The faster you move the products down the assembly line, the fewer hours you have to keep the lights on. Across many different kinds of industries, conveyors consistently increase efficiency by 15%.

An automated system can also help you cut back on fuel costs. You may have been using a large truck to move materials, rocks, or dirt. If you do this with a large truck every day, your costs will add up pretty quickly. Conveyors are much more efficient when it comes to fuel and power consumption.

Downtime is Reduced

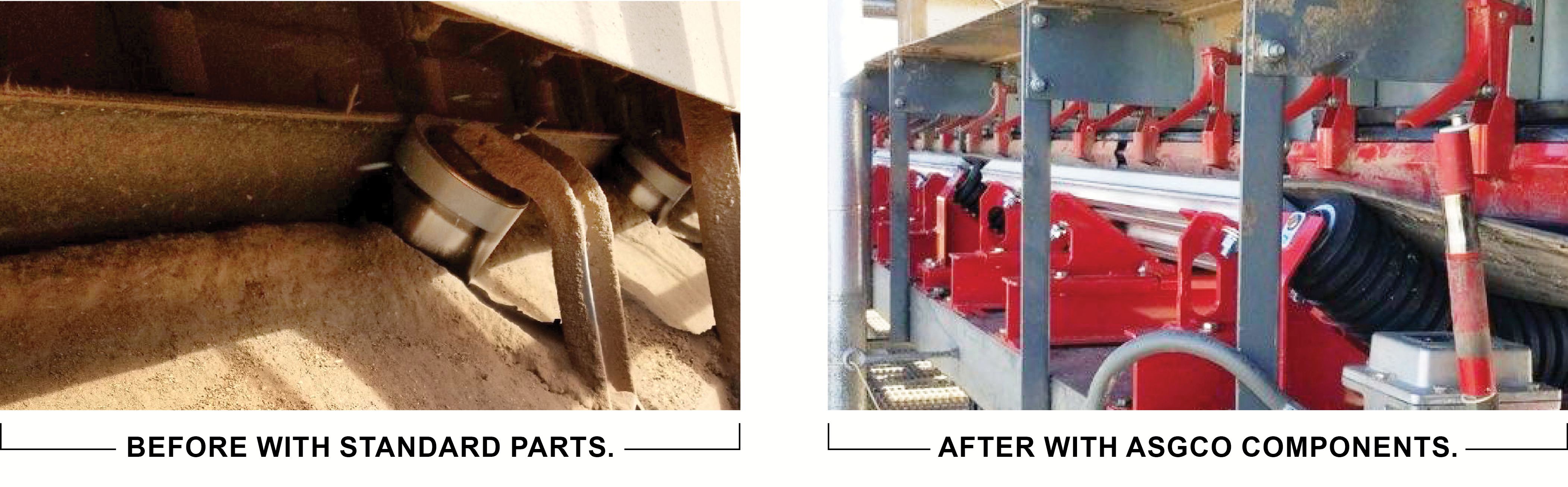

Another benefit of a conveyor system is that it reduces downtime. Even if your factory has a truck or forklift, you still need manpower to load and unload the vehicle and then drive it. With the flick of a switch, you can keep a conveyor working consistently, providing continuous loading and offloading — as long as it doesn’t break down. When you go with a top-of-the-line conveyor system, you won’t have to repair it quite as often.

Conveyors are Safe

A safer workplace is a happier workplace. With the help of a conveyor, you significantly reduce your chances of operator injury from a worker that is pushing, pulling, or lifting a heavy load. Whether you’ve been carrying products by hand or by forklift — a conveyor system eliminates collisions. Now, all of your products will move straight down a fixed pathway. Without human error, you’ll have fewer breaks, spills, and drops to deal with. Thus, you won’t have to replace as many items, allowing you to meet the needs of your clients.

Companies usually construct conveyor systems with safety in mind, so there are many safety features. Additionally, ASGCO can provide training for properly using the equipment. This can help prevent problems as well as injuries on the job.

They Help You Stay Competitive

In many industries, conveyors have become commonplace. If you don’t have a top-quality automated movement strategy, your business may fall way behind the competition. It helps with productivity as well as quality control and customer service. When your conveyor consistently provides the same product each and every time, consumers are able to count on your company. They know exactly what they’re getting when they utilize your services.

There are Food-Grade Options

There are lots of different conveyor applications just within the food industry. A food-grade conveyor belt can help you take baking products from a raw, uncooked stage to a delightful and edible treat. On the other hand, you may use a conveyor to move fruits, vegetables, grains, meat, dairy products, and different types of beverages. When you design your conveyor, you must consider its hygiene, cleaning stops, energy efficiency, and minimization of waste. There will be certain rules and regulations that your system must meet. For example, the Baking Industry Sanitation Standards Committee sets the standards for all baking-related equipment.

You can Move in Either Direction

A lot of conveyors will move in both directions. This can be extremely helpful if you have products that have to go through a line multiple times before being ready to ship. You just need someone there to work the controls. If you need to slow the conveying system down at any part of production, that’s also an option. In addition, there’s no height limitation with a top conveyor system. Your factory may have multiple floors. A vertical conveyor can easily travel up and down your factory without the use of elevators or cranes. Generally speaking, a conveyor can travel anywhere you need it to at any time and in any condition.

Product Quality: Dust contamination can compromise the quality of the bulk materials being handled. In industries like bio-fuels (pellets), limestone, coal and other commodities where maintaining product size is critical. Containing dust ensures that the final product meets quality standards.

Product Quality: Dust contamination can compromise the quality of the bulk materials being handled. In industries like bio-fuels (pellets), limestone, coal and other commodities where maintaining product size is critical. Containing dust ensures that the final product meets quality standards.

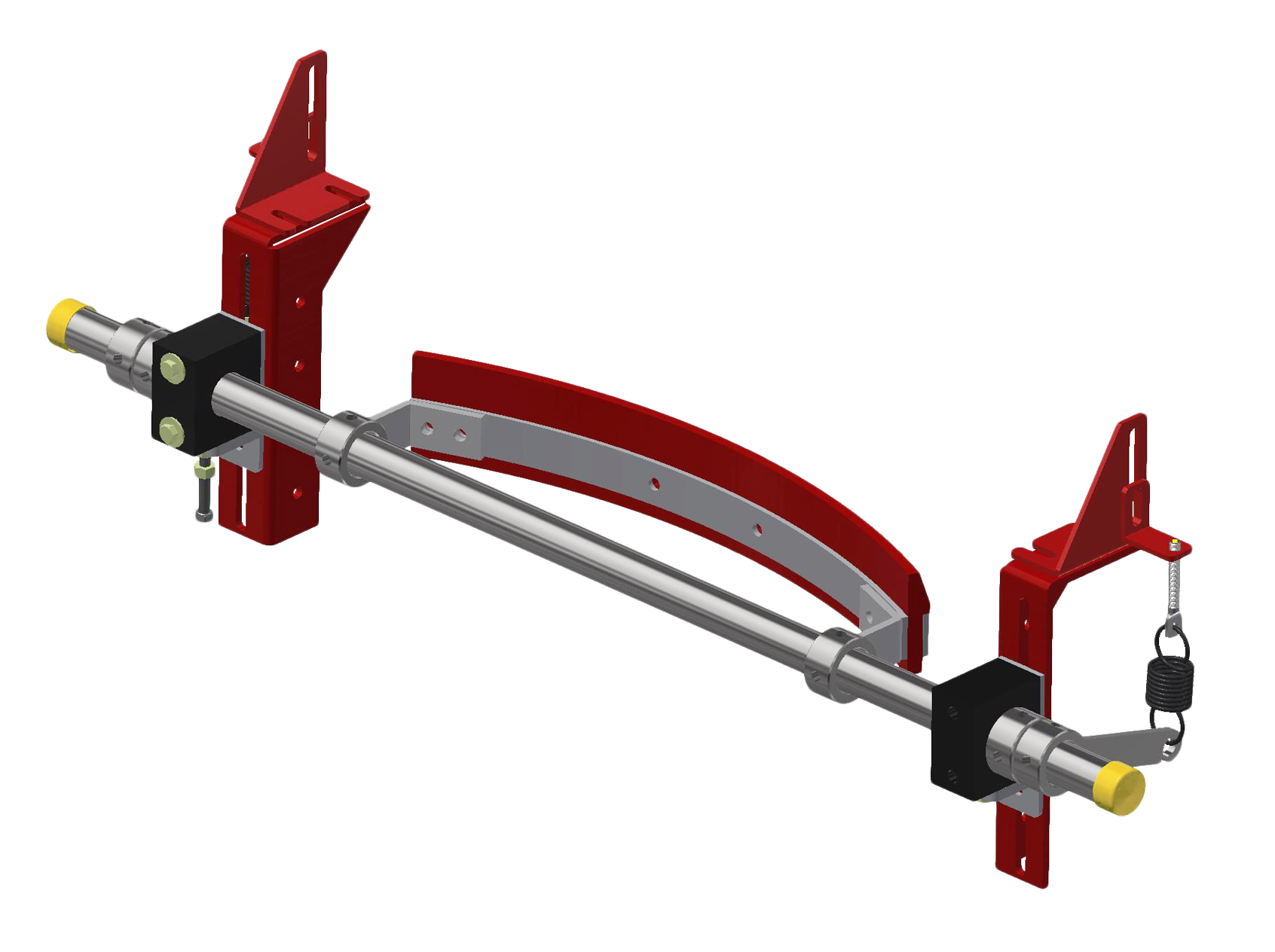

Preventing Belt Damage and Wear:

Preventing Belt Damage and Wear:

loading...

loading...