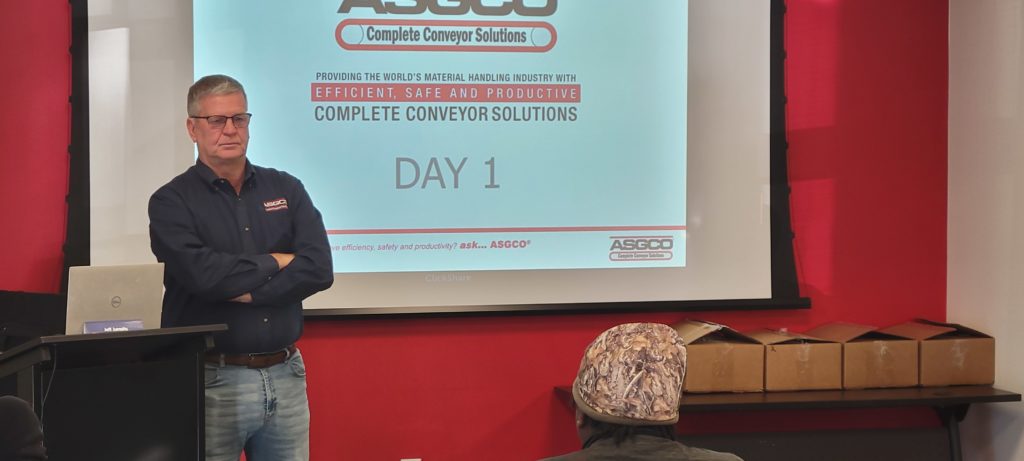

ACT™ Conveyor Training School

ASGCO® Conveyor Training School (ACT™) offers classes created to provide your team with the highest quality training to solve your conveyor problems. Each day your team will spend classroom time discussing the most common conveyor issues such as mis-tracking, spillage and dust control. The remainder of the day is spent in our hands-on conveyor training room, installing components on a full size working conveyor. Our experienced staff will show your team the ease of installing and maintaining ASGCO conveyor components. We can also develop the training course to meet your particular conveyor needs. And if you have a specific conveyor problem, we will teach you to discover the real issue, find out what others have done, brainstorm multiple solutions and implement the best one.

If you have a specific conveyor problem, we will teach you to discover the real issue and implement the best one.

The ASGCO® Conveyor Training Program (ACT™) offers a 2-day class created to provide your team with the highest quality training and to provide best practice solutions to your bulk material handling issues. Each day your team will spend classroom time discussing the most common conveyor problems such as conveyor belt mistracking, carry-back, load zone spillage, and dust control. The remainder of the day is spent in our hands-on conveyor training room, installing components on a full size working conveyor, to offer solutions to the above-mentioned situations. Our experienced staff will show your team the ease of installing and maintaining ASGCO® conveyor components and best practices.

Literature Downloads

Conveyors are the lifeline to an aggregate plant’s productivity. This training 2-8 hour class will provide the “Conveyor 101” program that has proven successful at facilities across the country.

- Conveyor systems, conveyor belts, their components, and how they affect your plant’s performance.

- Safety guidelines for working on or around conveyors.

- Tips on reducing fugitive material and dust (and solutions to control it) ideas on how to implement a conveyor inspection and maintenance service program that works for your plant. …and much more!

Literature Downloads

Optimize your company’ s conveyor belt splicing by attending ASGCO® Splice Training Course.

By attending our 2-day course you will gain valuable installation knowledge through hands-on training to prolong belt life and minimize maintenance concerns. Training includes plied and straight-warp belting, steel cord, and lightweight belting.

The aggregates, cement, mining, recycling, and other bulk material handling industries are challenged by the shortage of qualified people to work in the “field”. To remedy this situation, ASGCO® has founded the ASGCO® Conveyor Technician Program that offers a curriculum to prepare employees for careers as Conveyor Service Technicians.

This Degree Program will prove to be invaluable to the employees that will be learning valuable skills and trades to help themselves, their families, and the industries that we serve that help to build the infrastructure of America.

FOR ASGCO® EMPLOYEES ONLY

ASGCO’s Lunch and Learn is an on-site 2-4 hour customized training program. ASGCO’s Team of Conveyor Product and Service Managers will facilitate this session, which will provide a strong basis for attendees to learn more about maintaining and troubleshooting their conveyor systems.

Literature Downloads

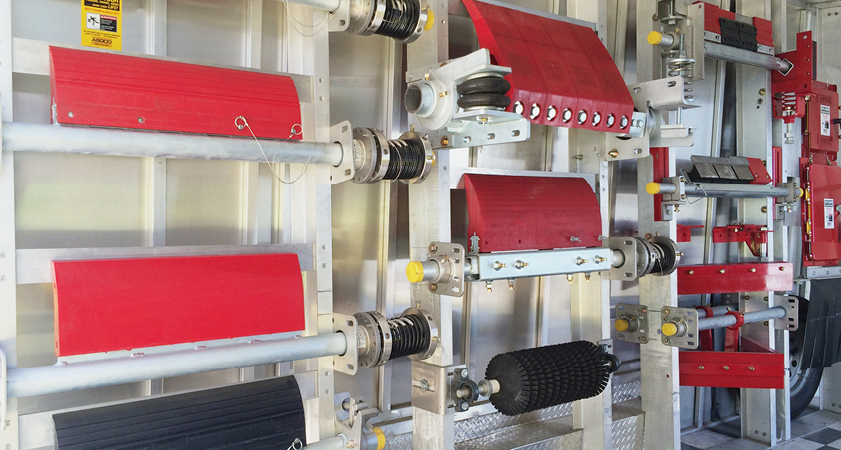

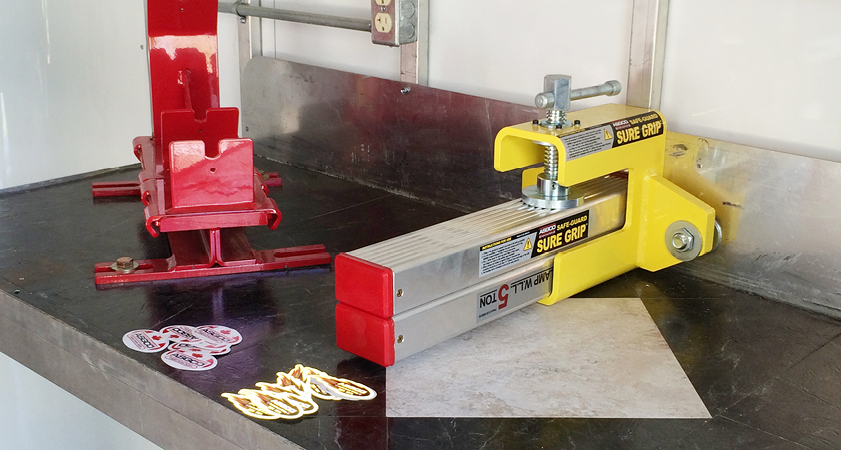

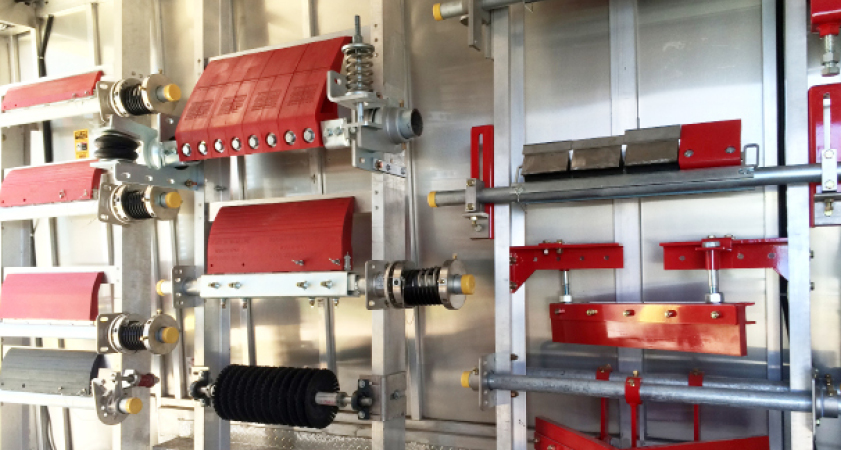

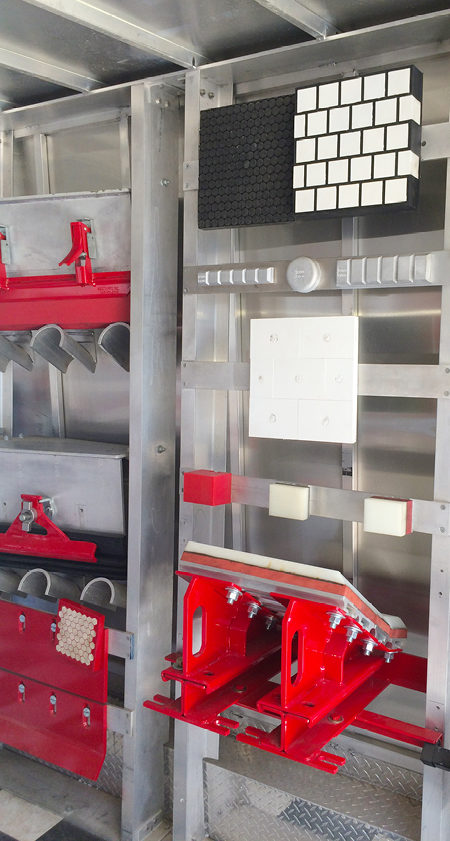

The ASGCO® Mobile Showroom showcases a broad range of quality ASGCO® products such as belt tracking idlers, primary and secondary belt cleaners, lagging and skirting samples, wear products, scales, and load zone support items.

- You will be able to actually handle and inspect our products for size, shape and features and get answers to all of your questions.

- Our products are mounted inside the showroom trailer for easy access.

Literature Downloads

Conveyor are the lifeline of your plant’s productivity. Sign up and learn how our programs have proven successful at facilities across the country.

These free webinar classes will help you discover:

- Conveyor 101

- Importance of Belt Cleaners

- Conveyor Safety

- Track, Train, and Troubleshoot

- Belt Cleaners