Screen Media

Vibrating Screens deliver unmatched precision performance – dependable production even under adverse operating conditions, or when handling the most abrasive material types. Rubber screens are used for the separation of Sand, Gravel, Granite, Quartzite, Limestone, Coal And much more…

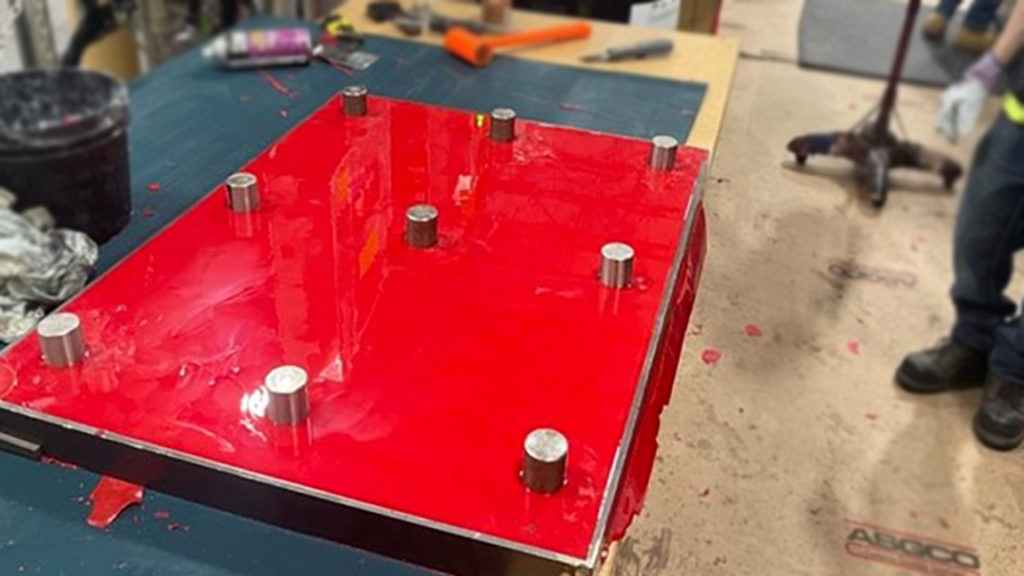

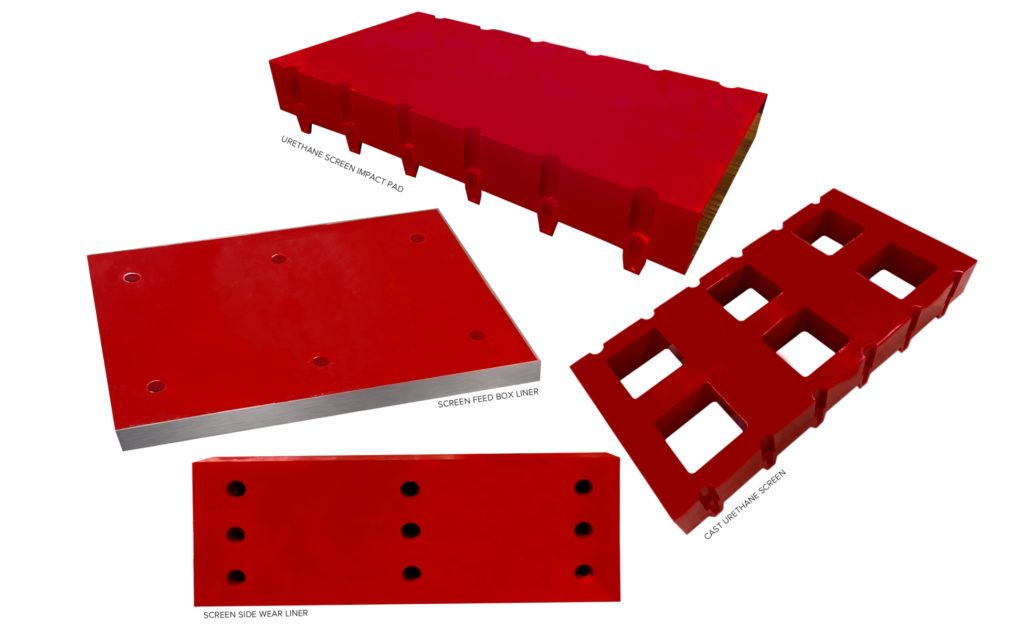

ASGCO® has expanded the use of their Cast Urethane products to include screen wear parts. All of our urethane wear products are cast from our exclusive ASGCO-thane™ polyurethane compound with a durometer of 80/85, along with steel backing plate for extra added support.

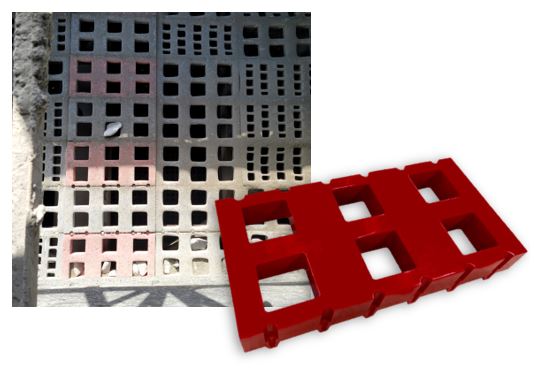

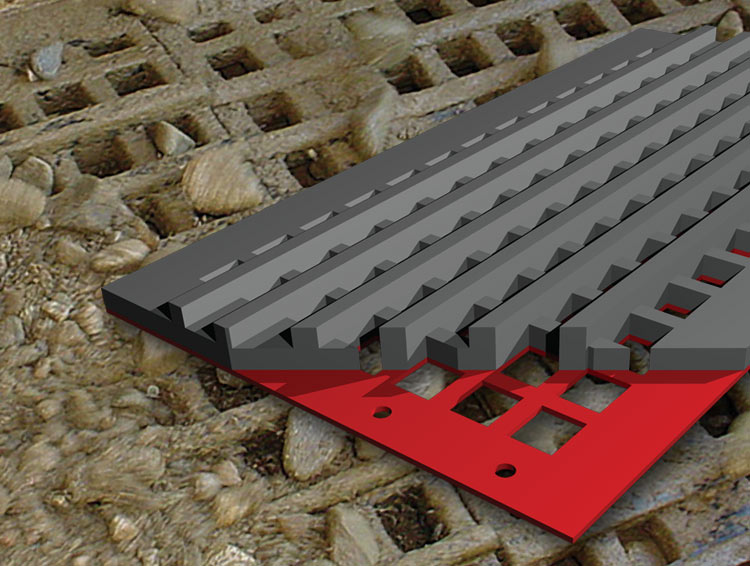

BullDawg™ Modular Screens

BullDawg™ screen panels are manufactured with the highest quality, mine duty, open cast urethanes and additives available anywhere in the world! They are manufactured and supplied in a range of durometers and custom structural designs to meet any and every screening application. From primary scalping to dry and fine wet screening – ASGCO BullDawg™ screen panels are tried and plant proven to be the best.

FEATURES & BENEFITS:

- Superior impact, abrasion and wear resistance.

- The standard for 1′ x 1’ and 1’ x 2′, and custom sizes on request

- Exclusive staggered pattern and tapered openings for increased efficiency

- Openings from 20mm to 4″

- 30 to 100mm thick panels; can include dams and diverters

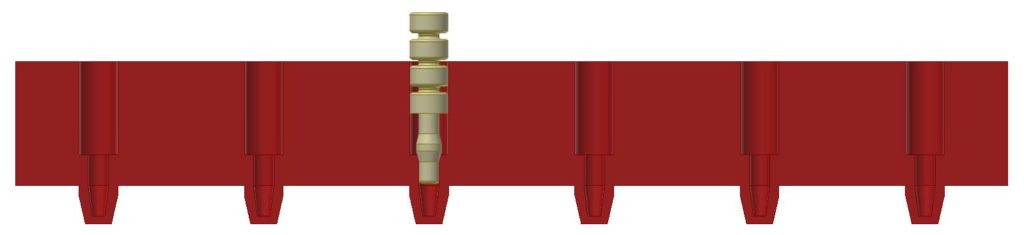

- Pin and Leg Systems and Bolt down fastening systems available

Pin & Leg Systems

- Modular open-cast Pin & Leg Panels are compatible with all 1′ x 1′ and 1′ x 2′ systems.

- Proprietary ASGCO open-cast polyurethane design creates strong yet flexible non-blinding panels

- Open-flo system offers reduced areas for binding and increased open areas

- Solid pin design for quick, easy installation & removal

Bolt down Systems

- Bolt down panels are designed and manufactured to suit the application

- Steel-backed reinforcement for high impact resistance

- Materials are available to optimize wear life

- Options range from softer urethane with greater impact resistance to higher durometers for greater abrasion resistance for fines and wet applications

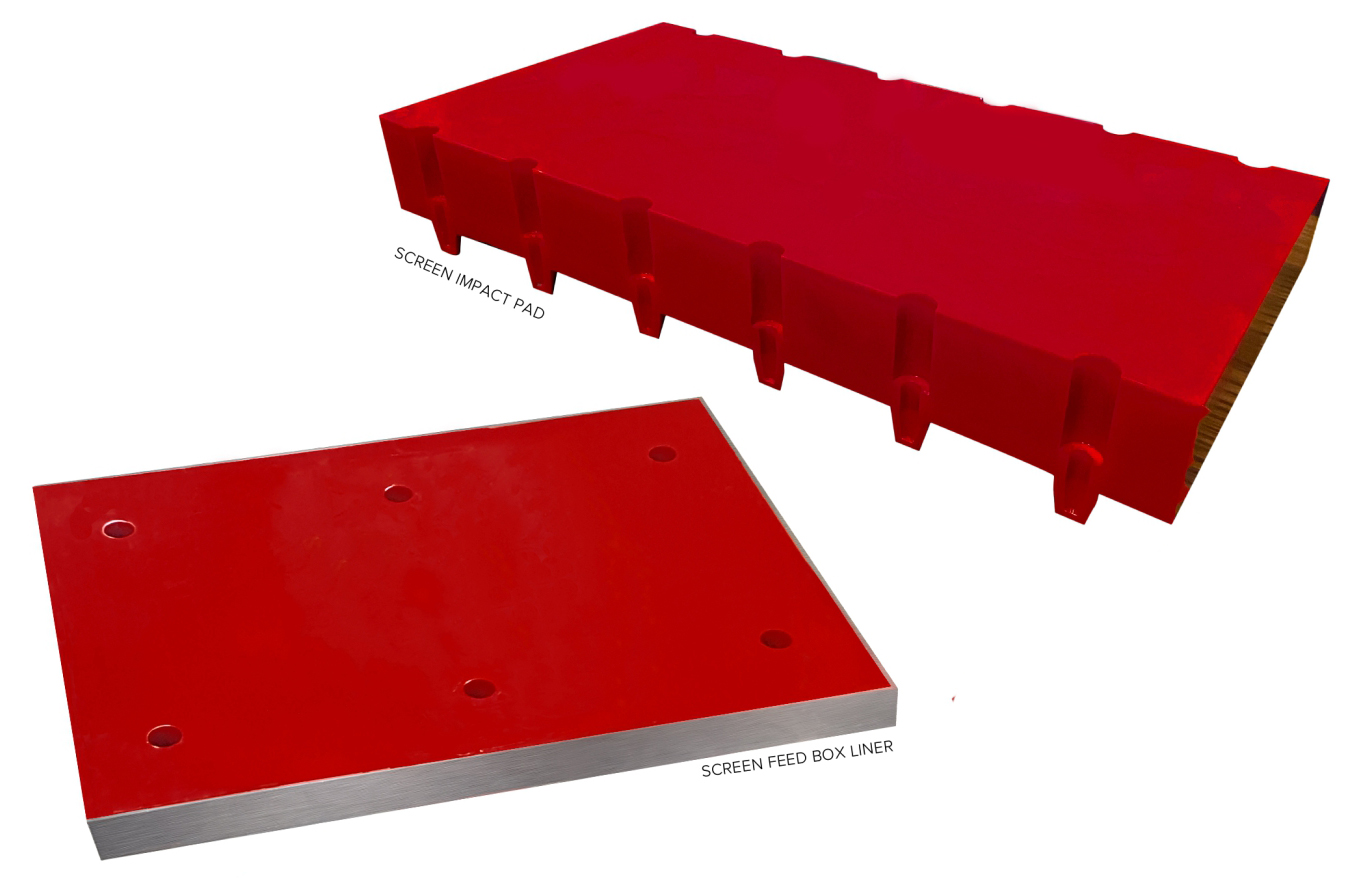

Impact Pads and Feed Box Liners

BullDawg™ Impact pads and feed box liners are manufactured with the highest quality, mine duty, open cast urethanes and additives available anywhere in the world! Screen Feed Box Liners are patterned for a direct replacement of the current liner configuration being used, or depending on the wear characteristics change the layout for maximum wear life. Liners have the ability to have various sized and shaped ceramics inserted to increase the longevity of the liner.

FEATURES & BENEFITS:

- Superior abrasion and wear resistant high-grade polyurethane compounds last longer and offer superior abrasion, cut, and tear resistance when compared to rubber.

- Higher load-bearing capacity for better compression set, and superior tolerance to greases, oils, oxygen, and ozone.

- Steel backed or fully framed in steel

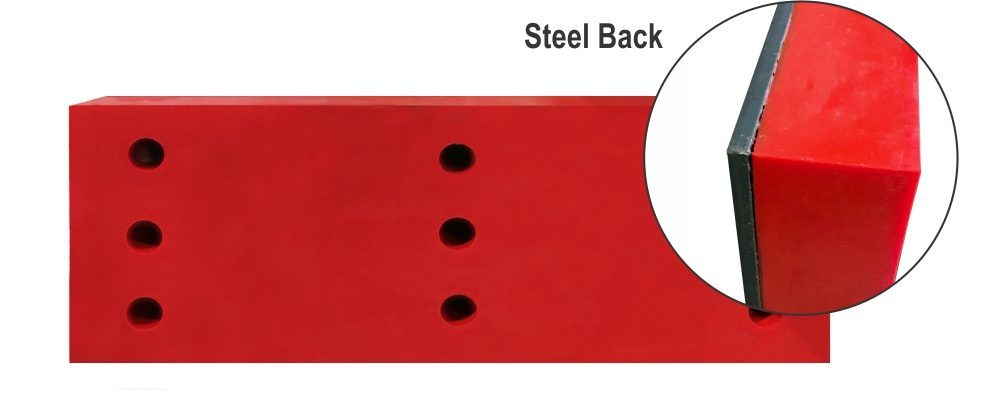

SCREEN SIDE WEAR LINERS

BullDawg™ screen side wear liners are manufactured with the highest quality, mine duty, open cast urethanes and additives available anywhere in the world! Screen Side Wear Liners are steel backed or boxed in with mild steel or hard plat to prevent premature edge wear or damage. Bolt patterns, sizes and thickness are fully customizable to increase the wear life for your operation. In house engineered to allow for an ease of duplicity.

Literature Downloads

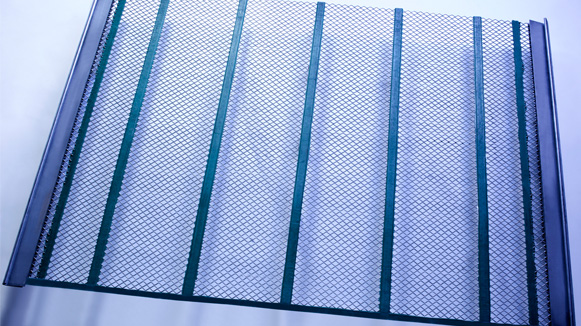

Wide range of opening size and thickness available. Rubber screens are used for the separation of Sand, Gravel, Granite, Quartzite, Limestone, Coal And much more…

STANDARD OR CUSTOM SIZE SCREENS

ASGCO® offers standard screening systems as well as custom designed screens to fit all makes of screening equipment, giving you a cost-effective solution.

Drawings, parts and measurements are given to our experienced professionals in order to create custom designed screens or replace existing screens.

RUBBER SCREENS

High resistance, available in many thickness measurements, bridge wideness and opening placements depending on the rubber screens usage and requirements.

FEATURES & BENEFITS:

- Extended wear life in dry applications

- High impact resistance

- Toughness – rubber will absorb and bounce back from high impacts that would break AR plate or comparable materials

STEEL-BACKED SCREENS

These screens are designed with a steel frame to reinforce the rubber screen for medium impact/high wear applications.

FEATURES & BENEFITS:

- Full steel backing can support heavier loads even as the panel wears thin

- Openings in the steel backing allows near size particles to either be knocked through or out of the opening by overriding coarse materials, thereby preventing plugging and increasing productivity

- Superior wear life and efficiency

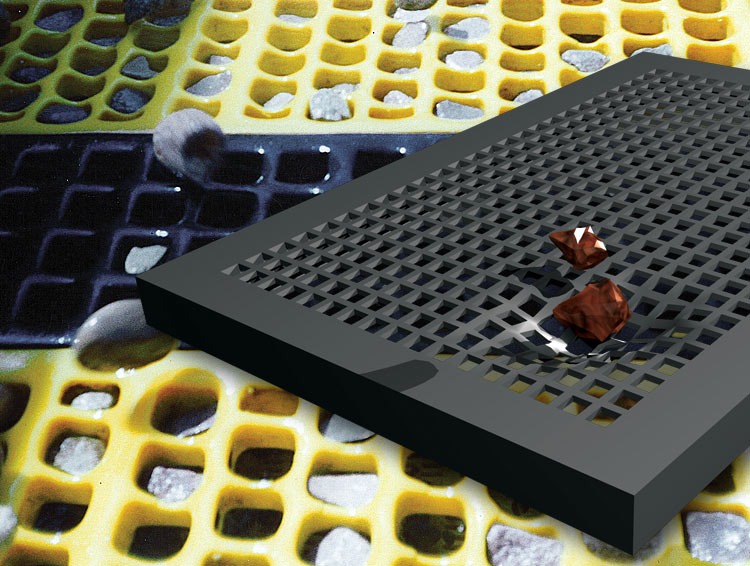

MODULAR SCREENS

Modular screens are blended with a high grade natural rubber and vulcanized for long life against wear . Many styles are available to fit your screening application. (1 ′ ′ x 1 through 1 x′ ′ 4 panels).

FEATURES & BENEFITS:

- Modular screens are easy to install and move around the deck to maximize wear life .

- Lab tested rubber compound gives long life and protection against impact, cut, tear and abrasion.

- Customization is available to maximize the products effectiveness.

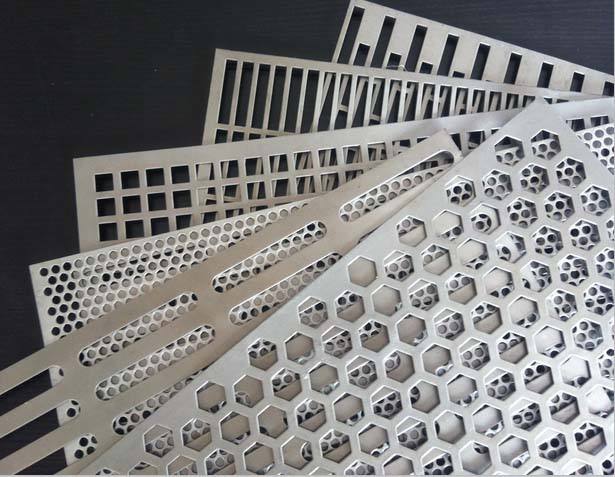

A Highly Versatile Material Available in many patterns. Quality perforated stainless steel can be used in several applications because it is strong, resistant to corrosion.

PERFORATED PLATES

ASGCO®’s perforated plates, also known as punch plate, are an essential part of many applications. Perforated plates are manufactured from plate steel and contain holes varying in size and shapes, depending on the application.

FEATURES & BENEFITS:

- High impact strength and long wear resistance

- Profile Shapes include but are not limited to round, square, rectangular, hexagon/diamond and slotted.

- Plates can be fabricated from mild steel to AR 400 up to 3/4” thick and up to 5’ x 10’ in size.

Literature Downloads

ACCESSORIES FOR THE AGGREGATE, MINING AND

INDUSTRIAL MARKETS

SCREEN ACCESSORIES

Our comprehensive lines of accessories are priced right to help customers maintain their budget and keep operations running smoothly.

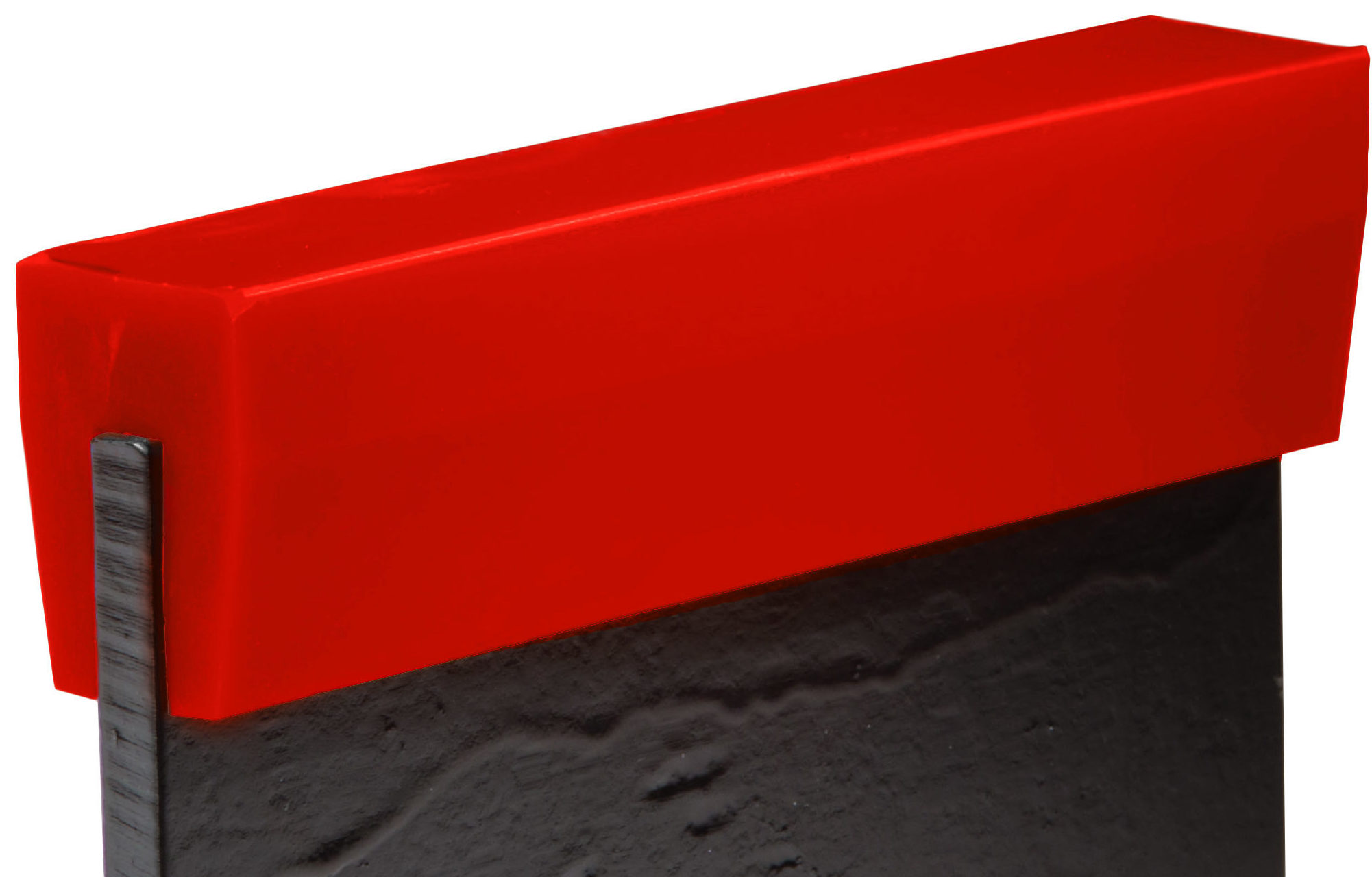

URETHANE BUCKER BACK

BAR CHANNEL

Also referred to as buffer strip, bucker-up strip, buffer channel and crown bar channel. Lasts 5 times longer than conventional rubber.

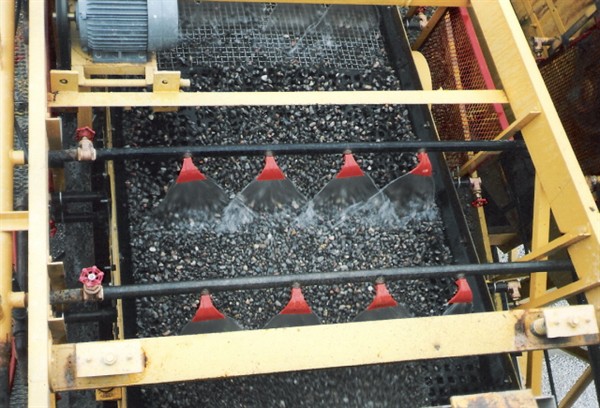

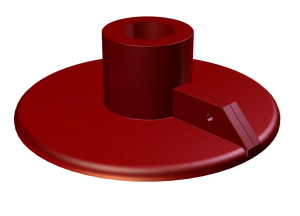

SPRAY DEFLECTOR

To Improve screen efficiency and material washing performance, install A SGCO® Urethane Spray Deflectors on screen spray bars. ASGCO® Urethane Spray Deflectors are developed for long service life in high wear applications.

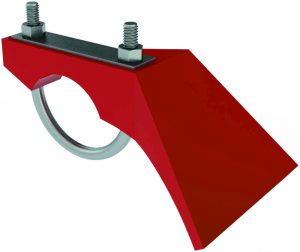

SPRAY BAR SHIELD

The ASGCO® Spray Bar Shield easily attaches to your current spray bar to deflect spray and divert it. Designed for screening and crushing applications. A SGCO® Spray Bar Shields are molded with 70A durometer high performance urethane. Fastening hardware included.

TENSION RAILS

The right tension rail will ensure proper tensioning and installation of your screens which will prolong your screen ’s media efficiency and life. An adequate tension tail matches the exact length of your screen and ensembles perfectly with your screen’s hook.

Literature Downloads

SAMSCREEN REPLACEMENT SCREENS AND WEAR

PARTS FOR SCREENING

SAMSCREEN

Samscreen offers replacement screens and wear parts for a wide variety of screening applications. Our replacement screens and wear parts are created for virtually any screening application, and for the industry’s most popular screening machines, so if you need a replacement screen, chances are, Samscreen either has it in stock or can manufacture it to your specifications. Create custom designed screens or replace existing screens.