CEMENT INDUSTRY

Our modern world is inconceivable without cement. It is the basic building material for the most varied construction tasks and is the most important component for manufacturing concrete.

The cement industry forms an important part of our economy. The continued anticipated growth of the cement market this year will place more demands on cement facilities to meet higher industry standards. New technologies and industry innovations are being introduced every day.

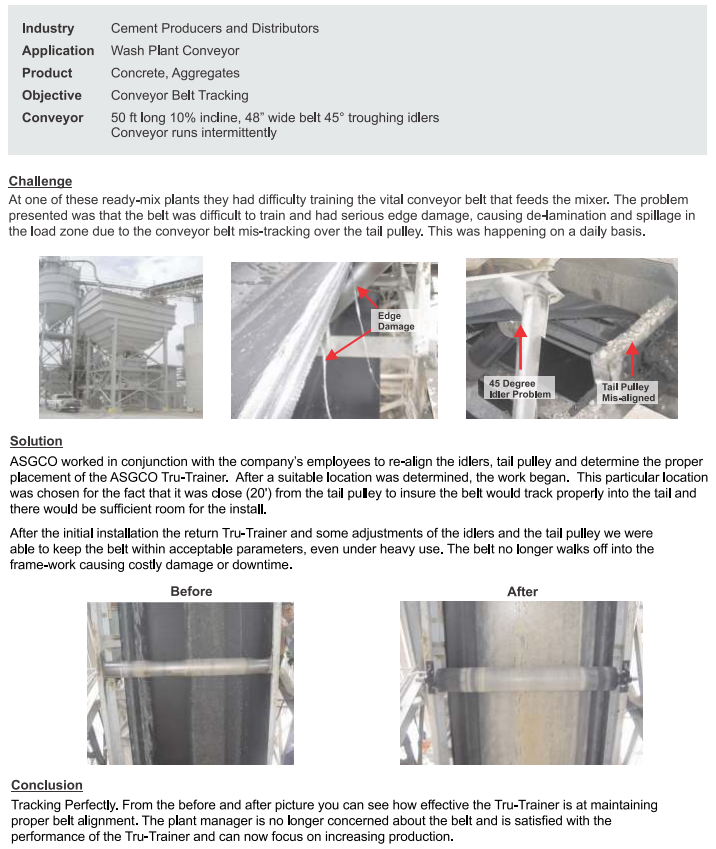

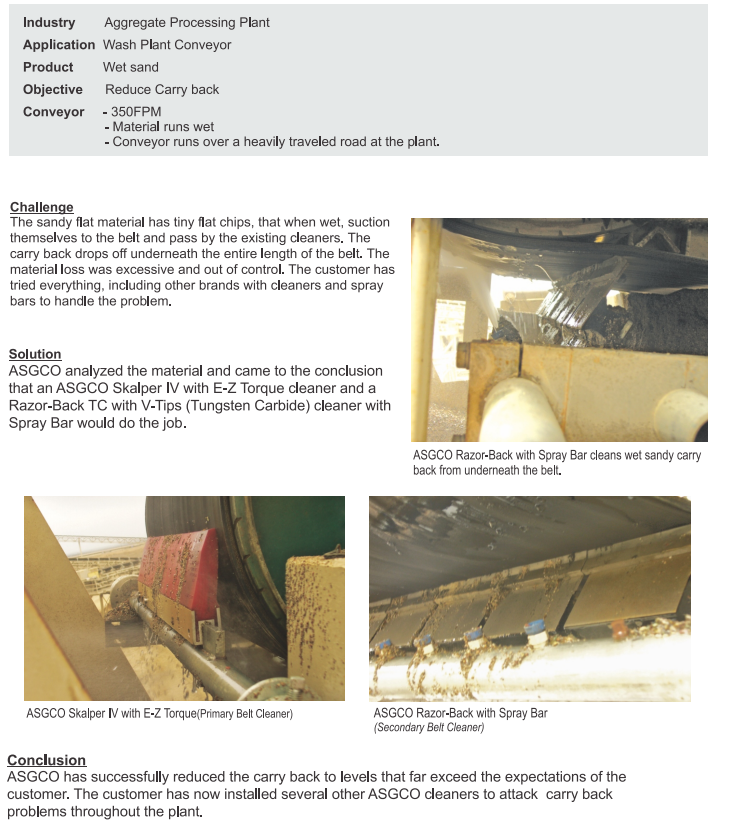

Cement plants take pride in an exceptional record of efficiency, safety and productivity while always seeking the newest techniques, systems and equipment. ASGCO® strives to help your plant meet those goals through the development of high-quality products and services.

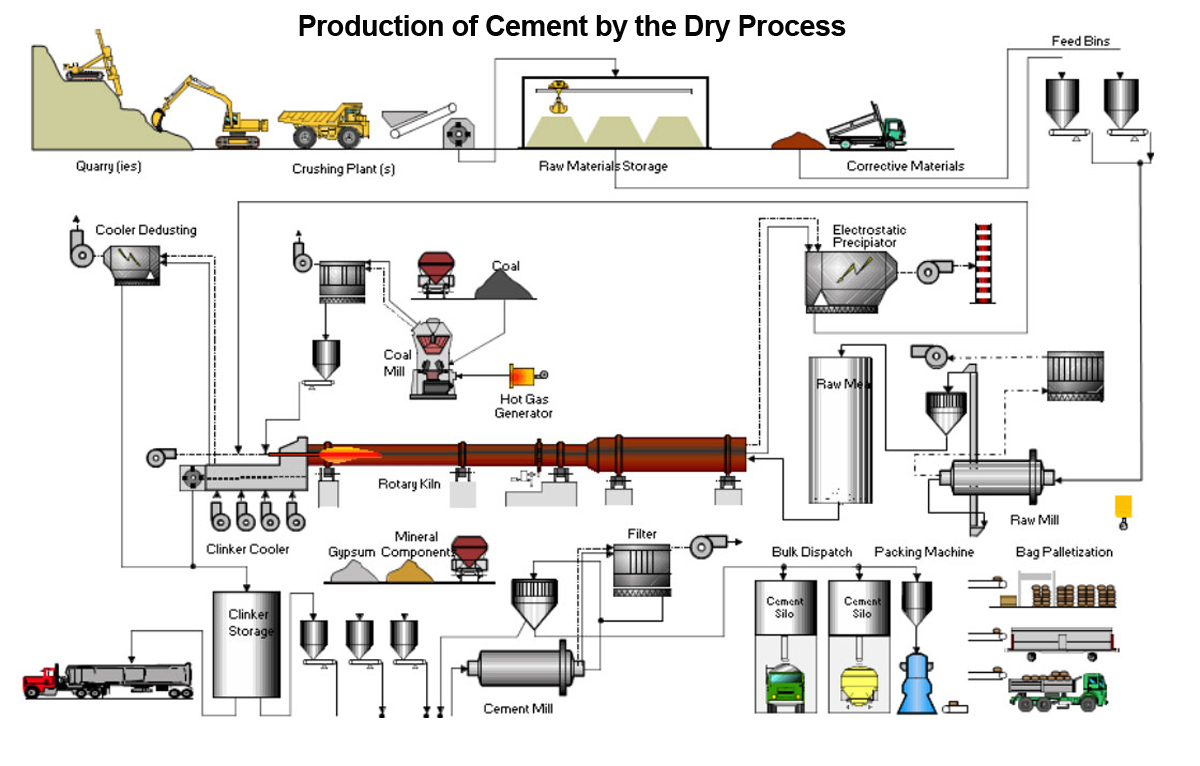

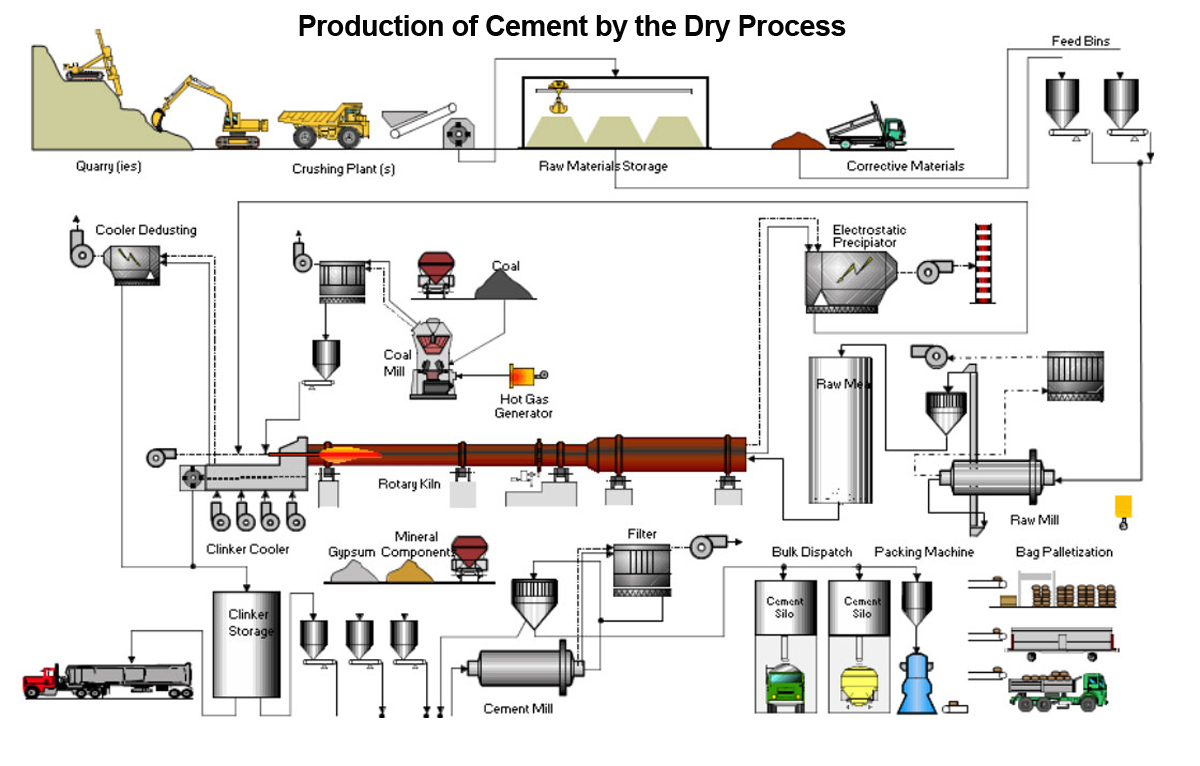

Production of cement by the dry process.

The most common way to manufacture cement is through the dry method. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process. The two processes are essentially alike except in the wet process, the raw materials are ground with water before being fed into the kiln.

Production completes after passing of raw material from the following stages:

-

-

- Raw material extraction/ Quarry

- Grinding, Proportioning and Blending

- Pre-heater Phase

-

- Kiln Phase

- Cooling and Final Grinding

- Packing & Shipping

Concrete is produced in four basic forms:

Ready-mixed concrete – the most common form, accounts for nearly three-fourths of all concrete. It’s batched at local plants for delivery in the familiar trucks with revolving drums.

Precast concrete products – are cast in a factory setting. These products are best known for their conventional 8-by-8-by-16-inch block but can be molded into a wealth of shapes, configurations, colors, and textures.

Cement-based materials – in this category include mortar, grout, and terrazzo, soil-cement and roller-compacted concrete for use in pavements and dams. Also included in this category are flowable fill and cement-treated bases.

A new generation of advanced products – incorporates fibers and special aggregate to create roofing tiles, shake shingles, lap siding, and countertops

AGGREGATE INDUSTRY

Aggregates are building materials used in construction, including sand, gravel, crushed stone, and recycled concrete. Aggregates are mined and either used in their raw form (for example, as foundations) or serve as composite materials in the production of concrete and asphalt. End markets for aggregates include private residential construction, commercial construction, and publicly-funded infrastructure projects, with the latter consuming the most aggregates, usually for use in highway and road construction.

Aggregates are used as base materials in foundations, or as components in the production of concrete and asphalt. The diagram to the left demonstrates how aggregates are used in road construction; aggregates are clearly essential not only as a foundation for the roadbed, but also go into the cement that makes the road itself. When aggregates are used, they are an important part of the construction process.

Quarries are obviously essential to aggregates producers’ business; without quarries and the reserves they provide, there is no source of raw materials. Aggregates are usually shipped from quarries or production areas close to their end market. This is because even a relatively small amount of aggregates, in terms of value, can weigh several tons. Because most aggregates are transported by truck, transport over 50 miles is thus cost-prohibitive and infeasible. However, this can be circumvented to an extent by alternative modes of transport, specifically by rail or by water. For those aggregates producers with proper facilities, rail transportation provides a cheaper alternative to shipments by truck. Transport by barge is even cheaper, but is only available to those producers with access to coastal waterways.

Aggregates are not just for construction, a vast array of other products, many of which are taken for granted, are manufactured using materials derived from quarrying. These include: paper, glass, cosmetics and toothpaste to name but a few. Aggregates are also used in agriculture, food manufacture and water & sewage purification.