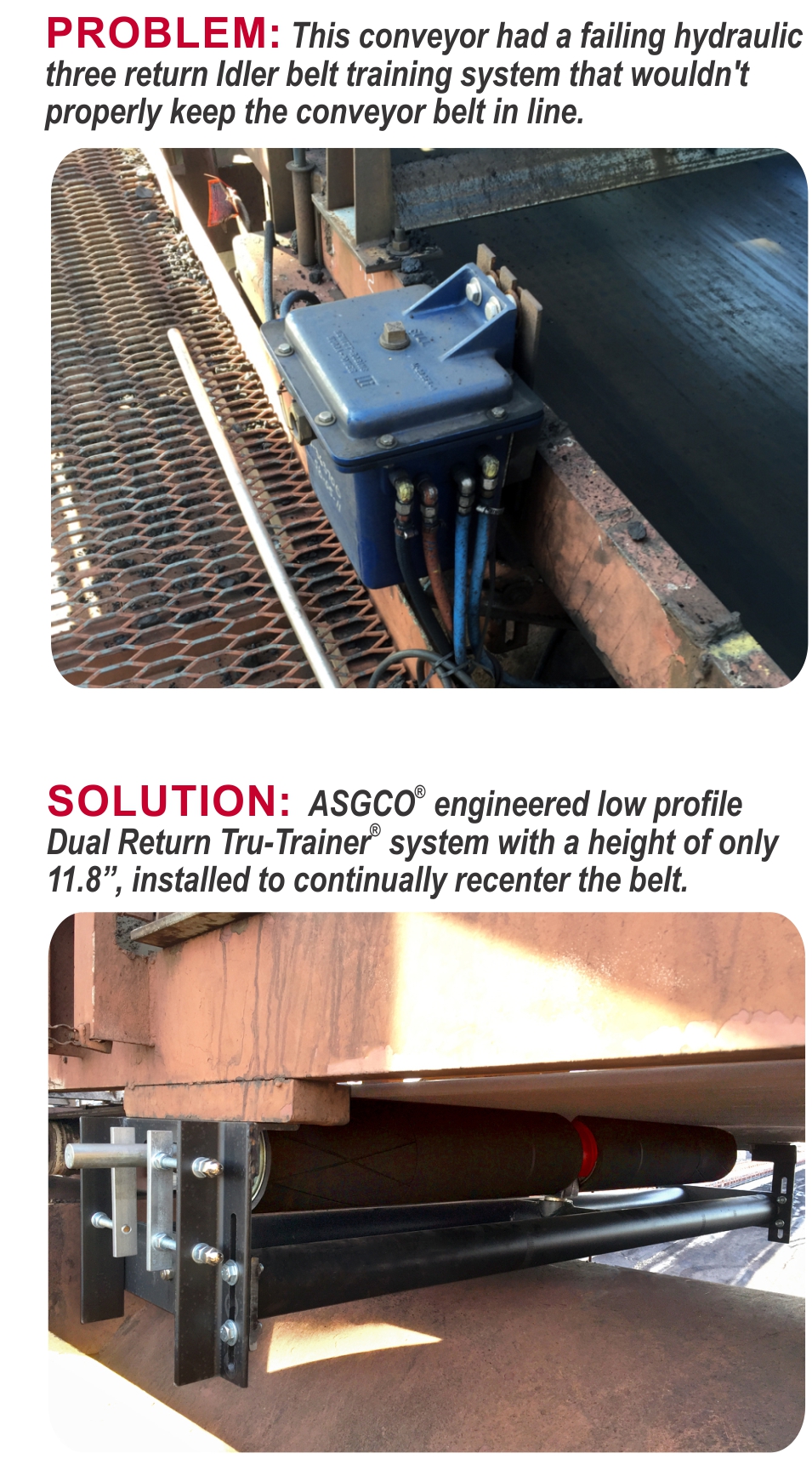

Challenge: For many years this conveyor had a hydraulic three return Idler belt training system that wouldn’t properly keep the conveyor belt in line. The plant was facing constantly downtime to repair the hydraulic system. Even when operational, the belt would veer off of center and come into contact with the structural supports, leading to critical damage to the belt and costly material spillage. To further complicate this application, the conveyor also has less than 13” of height to mount any type of return training roller. Options for eliminating the tracking problem were extremely limited by these space restrictions.

Solution: After ASGCO®’s technicians performed a complete survey of the conveyor system, the problem issues were identified. It was recommended that ASGCO® Tru-Trainer® was to be installed on the return side of the conveyor, 30 feet before the tail pulley. This position would allow the belt to run straight around the tail pulley and also be centered on the conveyor in the load point, reducing spillage and costly material loss. In addition, the rubber disk return idlers were replaced with flat return idlers, eliminating resistance to centering.

On several occasions, the belt became so severely mis-aligned, that it came in contact with the tail section of the support structure, leading to catastrophic damage to the belt, and causing extended downtime for the plant’s operations. The problem persisted upon installation of a new belt, and within 12 months, it needed to be completely replaced a second time.

Results: After installing two Low Profile Dual Tru-Trainers® about 20′ from each stationary pulley, the belt is maintaining center alignment and the problem of belt damage and material spillage has been eliminated. The customer no longer has to shut down operations to repair the belt and the hydraulic system, or to spend valuable hours cleaning up spilled material. Performance has been greatly improved and productivity is at an all time high. This particular customer is very satisfied with the performance of the Tru-Trainers®, and recently placed an order for two additional for a different 60” Stacker Reclaimer Conveyor.

Tru-Trainer® Dual Return Idler

- Patented design does not rely on the

conveyor belt to activate - Designed for high speed /PIW conveyors

- Two separate tapered rolls mounted into

the pivot mechanism can be individually replaced - Enhanced sealing/bearing system for aggressive

mining conditions - Total Satisfaction Guarantee (TSG)

- Reactionary in both wet and dry conditions.

The Tru-Trainer® series of conveyor belt tracking idlers are a patented design that offers the most reliable and re-active belt tracking idlers available today.