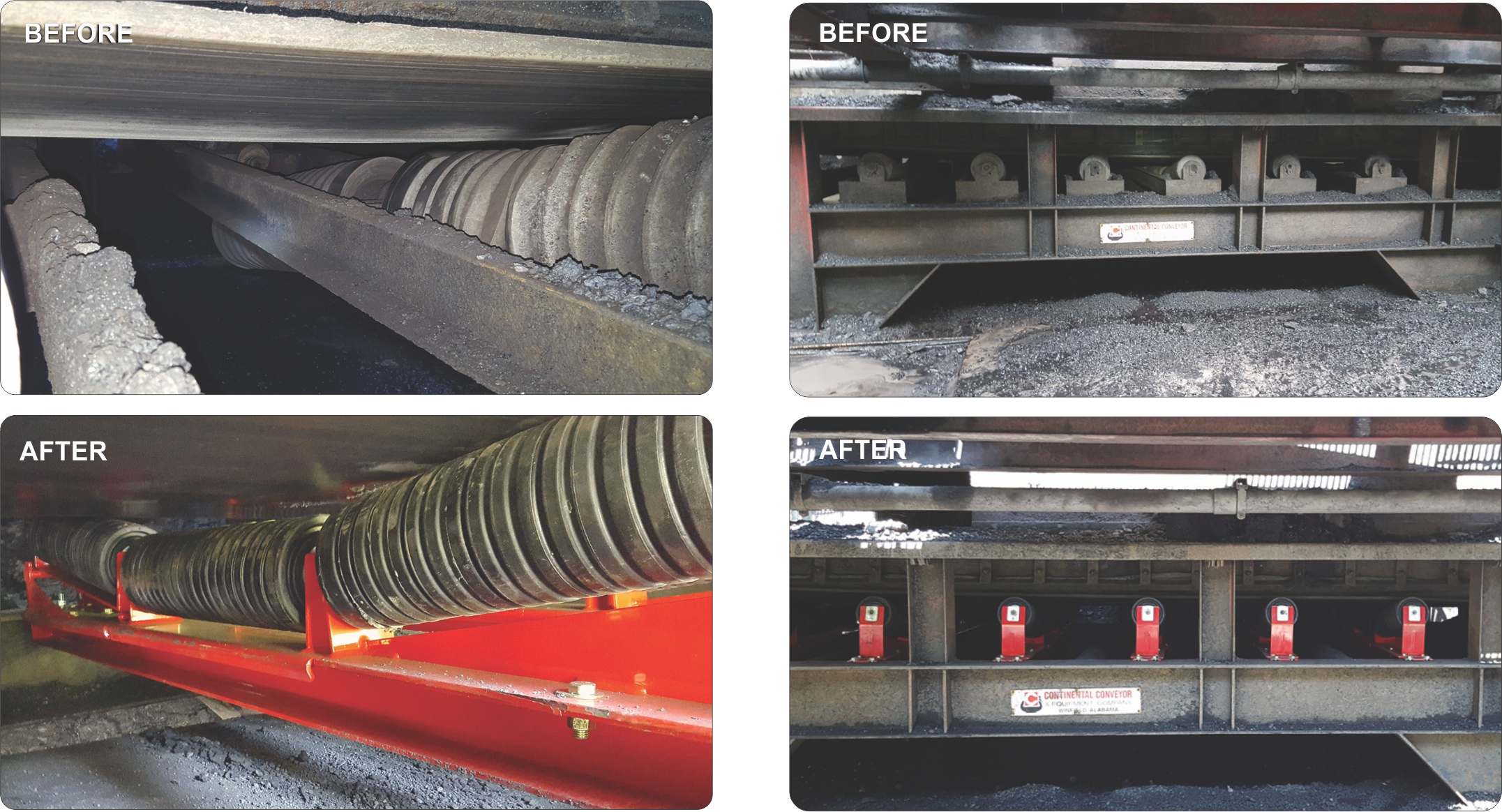

Challenge: The challenge was to be able to remove and to replace the impact rollers in this tail

section with access limited to only one-side, while providing an easier alternative to servicing

them in the future.Many of the existing impact rollers had already failed. Some were stuck,

worn flat, shafts broken,and some were even missing. These impact rollers were at a 10° trough,

like many of the tailpiece style sections, where changing one of the impact beds was very difficult.

The ‘off’ side of the transfer was blocked by a concrete footing or pillar. Any servicing that

needed to be done on this side was cumbersome and in some cases depending on the problem,

impossible.

[line]

Recommendation/Solution: The suggested solution was to remove the old impact rollers that

were already deteriorated and to install One Sided Slide-lers™. The One Sided Slide-ler™ is designed

to be maintained from one side of the conveyor, allowing you to replace the rolls with minimal

downtime. This is the ideal system when access is only on one side of the conveyor or where a

conveyor is located against the wall or high in the air with the catwalk on one side.

Results: The installation was problem free, even though the clearance was at a minimum. Due to the

modular design they are now able to change out the rolls without having to remove adjacent idler frames.

The ‘off’ side,middle and near impact roller can now be changed by removing four easy to reach bolts.

PROBLEM SOLVED! The customer is very pleased with the results and the conveyor is back in working

order, no more concerns about failing impact idlers!