Challenge: This copper mining facility needed to remove the residual carry-back material

from the primary belt cleaner to run more efficiently and to reduce downtime. They were

having to clean once a week, taking took up to 3-1/2 hours each time, causing increased labor

for housekeeping.

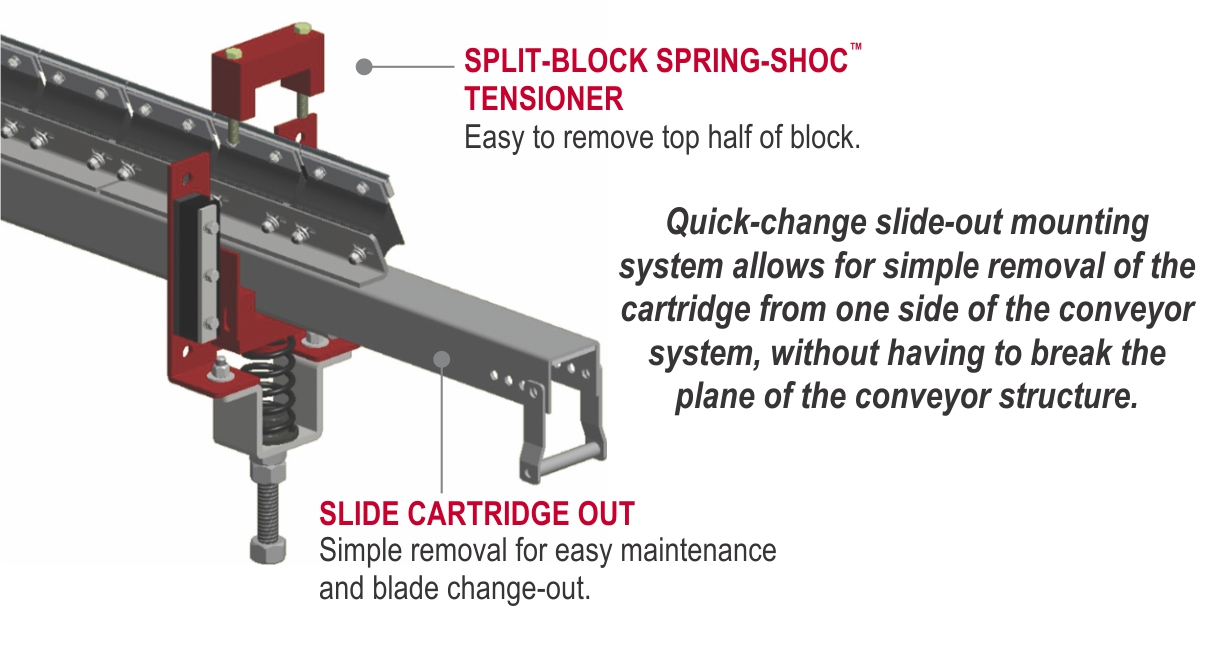

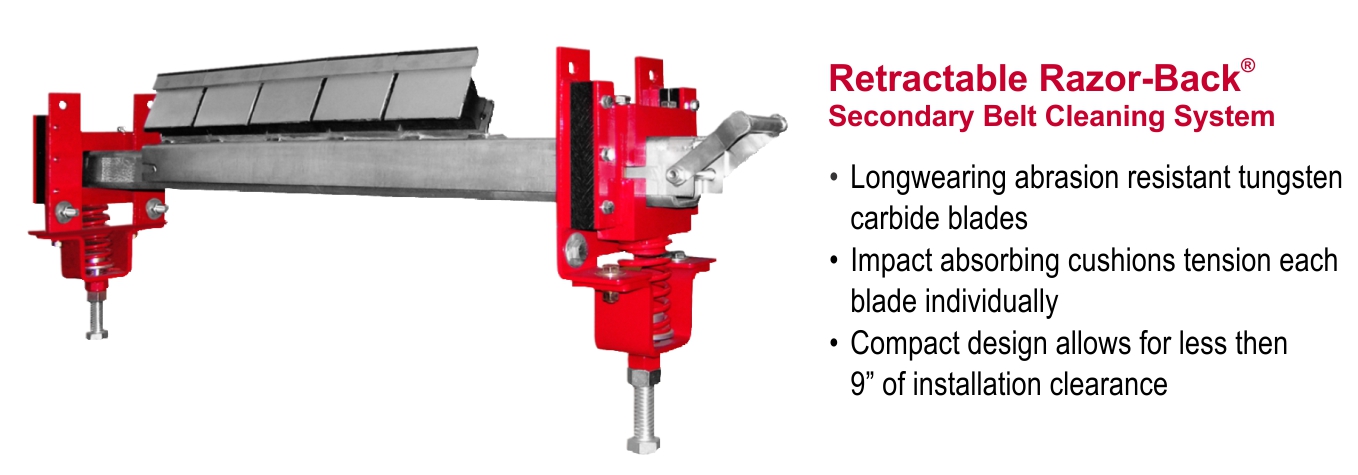

Solution: It was recommended to install (4) Retractable Razor-Back MDX® System with

Spring-Shoc® Tensioner Systems. Installation of (2) Retractables with V-Tips close together

with a snub idler between them and another set of (2) Retractable Razor-Back MDX®’s

with U-Tips, 20 feet away to squeegee the water off. The Retractable Razor-Back MDX®

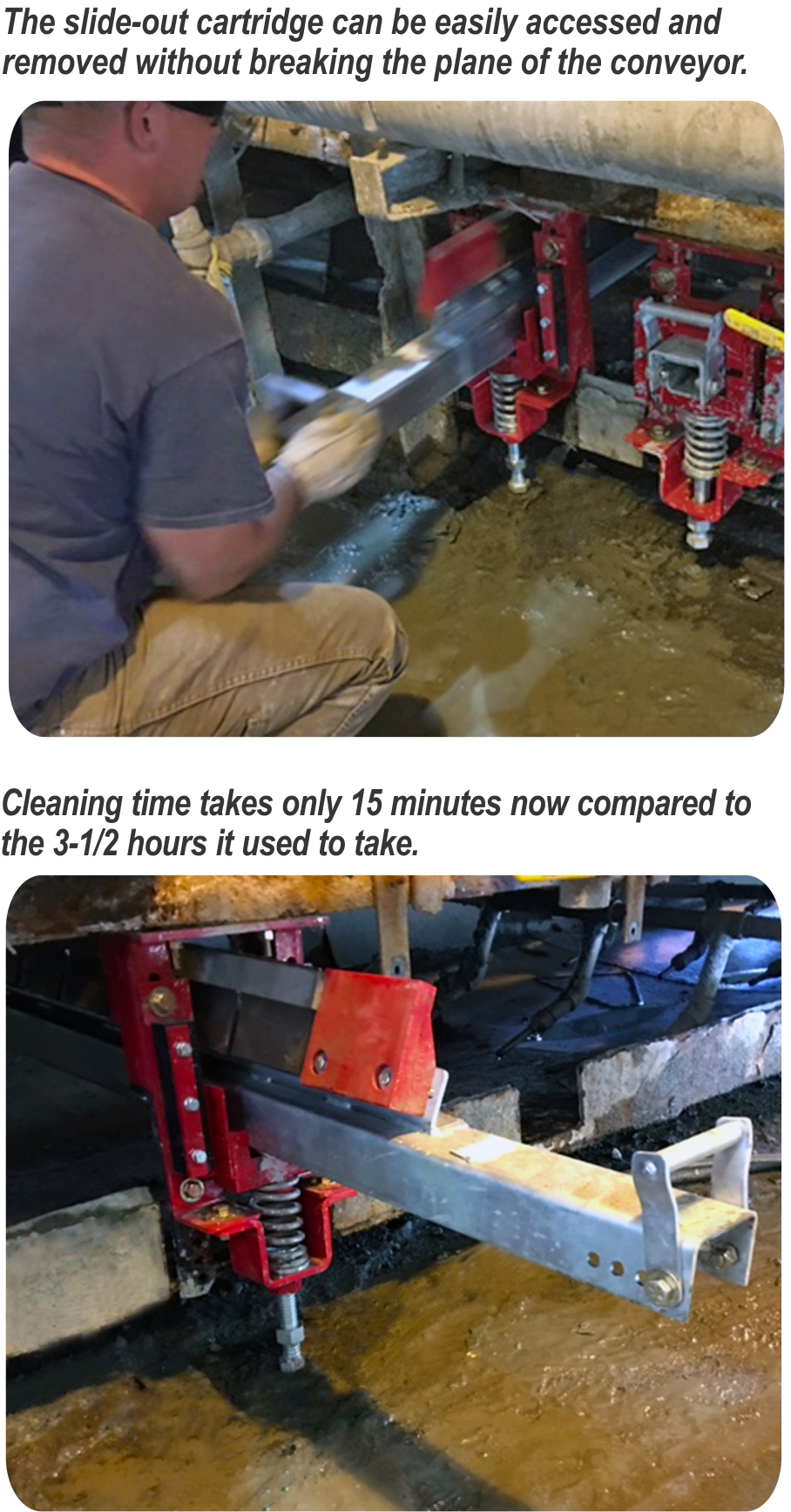

cleaning system with it’s slide-out cartridge can be easily accessed and removed without

breaking the plane of the conveyor, decreasing downtime, allowing for safe, access and

ease of maintenance. The long-wearing, abrasion resistant blades maintain a consistent

edge against the conveyor belt.

Results: The customer is extremely pleased with the System. The cartridge simply slides

out from one side, the tips of the blade are cleaned off and/or serviced, and then slid back in

without breakingthe plane of the conveyor. The area is now spotless and the cleaning time

has been greatly decreased now and only takes 15 minutes compared to the 3-1/2 hours it

used to take. And the Spring-Shoc® Tensioner keeps positive pressure across the belt.