ASGCO®’s Dual Skalper® Primary Belt Cleaners Solve Major Carry-Back Problems at a Canadian Smelter Complex Nickel Mine.

Problem:

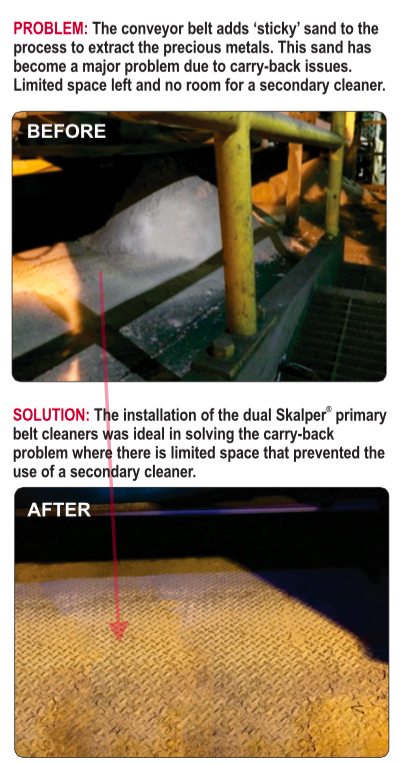

The conveyor belt adds the sand to the process for extracting the precious metals. All ore from any of their sites has to pass through this filter plant at some point. This sand belt has become a major problem due to the carry-back issues. The sand is very “STICKY” and therefore very hard to clean. Also there is limited space within the head chute preventing them from using a secondary cleaner. They were currently using a competitor’s pre-cleaner and also an Air Knife. These were not working and a lot of “Man Hours” were being spent shoveling the carry-back material back onto the belt.

Solution:

After we addressed the carry-back and space limitation issues, we recommended installing dual Skalper® primary belt cleaners to solve the problem. The Skalper® primary belt cleaners with E-Z Torque® tensioners are easily maintained from one side of the conveyor and are self-adjusting making it ideal in an area where there are frame restrictions.

The customer is extremely pleased with the results. Their “nightmare” housekeeping issue is resolved. This has led to an increase in production with less man-hours spent shoveling the sticky carry-back, which in turn has led to better overall morale and safety.

[line]

Skalper® Belt Pre-Cleaners:

- Patented siped self-sharpening blades

- All 304 stainless steel mounting system & tensioner

- Rubber corrugated dust cover

Our Skalper® series of conveyor belt pre-cleaners have been installed and have solved carry-back problems all over the world. The simple and highly effective Skalper® belt cleaner removes carry-back from the conveyor system.

[line]

The installation of the dual Skalper® primary belt cleaners was ideal in solving the carry-back problem where there is limited space that prevented the use of a secondary cleaner

[line]