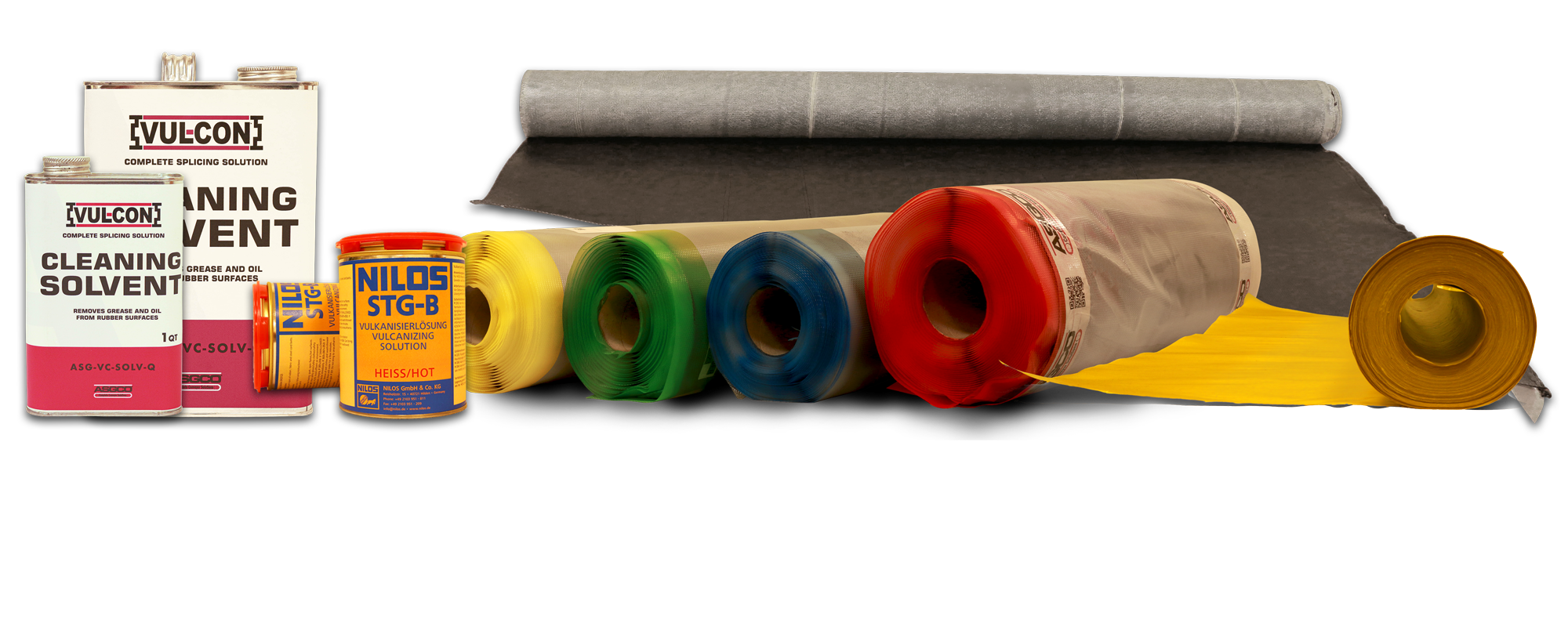

Hot Splice Materials

ASGCO offers a complete line of conveyor general purpose belt splicing materials. Whether you are performing a hot repair or performing hot vulcanized splice a belt. We stock hot vulcanizing cement, cleaning solvent, uncured rubber tie gum and uncured cover material as well as release paper and breaker fabric. Our hot splice material products guarantee excellent adhesion and performance, providing the conveyor belt splice technicians with very reliable and readily available “complete splicing solutions”.

Part Numbers

VUL-CON Fabric Belt Cover Stock is a specially formulated uncured rubber used in vulcanized conveyor belt step and finger splicing.

VUL-CON Fabric Belt Cover Stock is a specially formulated uncured rubber used in vulcanized conveyor belt step and finger splicing.

It is engineered for use as a cover rubber replacement material when splicing fabric conveyor belts.

Our high abrasion compound allows it to chemically bond to cured standard RMA Grade 1 and RMA Grade 2 cover rubber for conveyor belts.

| Part Number | Description | Dimensions (W x L) | U/M | Weight Lbs. kg | Weight Lbs. lbs | Color |

|---|---|---|---|---|---|---|

| ASG-VC-CS-0.063 | Vul-Con™ Cover Stock 0.063” (1/16″) | 20.5″ x 47′ | Roll | 15.4 | 34.0 | Red |

| ASG-VC-CS-0.125 | Vul-Con™ Cover Stock 0.125” (1/8″) | 20.5″ x 25′ | Roll | 16.9 | 37.20 | Yellow |

| ASG-VC-CS-0.188 | Vul-Con™ Cover Stock 0.188” (3/16″) | 20.5″ x 15.5′ | Roll | 15.4 | 34.0 | Green |

Part Numbers

VUL-CON Fabric Conveyor Belt Tie Gum Rubber is specifically formulated uncured rubber for vulcanized conveyor belt splicing.

VUL-CON Fabric Conveyor Belt Tie Gum Rubber is specifically formulated uncured rubber for vulcanized conveyor belt splicing.

It is engineered for use as a skim rubber replacement material for splicing fabric conveyor belts.

Our Tie Gum rubber compound allows for great adhesion to bond standard RMA Grade 1 and RMA 2 Grade fabric conveyor belts.

| Part Number | Description | Dimensions (W x L) | U/M | Weight Lbs. kg | Weight Lbs. lbs | Color |

|---|---|---|---|---|---|---|

| ASG-VC-TG-0.040 | Vul-Con™ Fabric Belt Tie Gum 0.040″ | 20.5″ x 51′ | Roll | 10.9 | 24.0 | Blue |

Part Numbers

![]() VUL-CON Silicone Release Paper is a specially formulated calendered Kraft-type paper with a special silicone non-stick coating.

VUL-CON Silicone Release Paper is a specially formulated calendered Kraft-type paper with a special silicone non-stick coating.

It is engineered for use as a release material between the uncured rubber and vulcanizing press.

It can be used in step splicing, finger splicing and steel cord splicing of all types of belts.

| Part Number | Description | Dimensions (W x L) | U/M | Weight Lbs. kg | Weight Lbs. lbs |

|---|---|---|---|---|---|

| ASG-VC-SRP | Vul-Con™ Silicone Release Paper 43.31″ x 164′ | 43.31″ x 164′ | Roll | 5.1 | 11.20 |

Part Numbers

NILOS® Hot Vulcanizing Cement is a specially formulated one-part cement for vulcanized belt splicing.

NILOS® Hot Vulcanizing Cement is a specially formulated one-part cement for vulcanized belt splicing.

It is engineered for use as a tackifying agent for cured and uncured rubber materials.

| Part Number | Description | Size | U/M | Weight Lbs. kg | Weight Lbs. lbs |

|---|---|---|---|---|---|

| ASG-VC-SRP | Vul-Con™ Silicone Release Paper 43.31″ x 164′ | 1 Liter | Can | 0.8 | 1.75 |

Part Numbers

Vul-Con™ Cleaning Solvent is a specially formulated industrial solvent, cleaner and degreaser.

Vul-Con™ Cleaning Solvent is a specially formulated industrial solvent, cleaner and degreaser.

It is engineered for use on all rubber, metal, and fabric surfaces. It is ideal for cleaning the splice area before applying cement and splice materials.

| Part Number | Description | Size | U/M | Weight Lbs. kg | Weight Lbs. lbs |

|---|---|---|---|---|---|

| M-ASG-VC-SOLV-Q | Vul-Con™ Cleaning Solvent Quart | 1 Quart | Can | 0.9 | 2.0 |

| M-ASG-VC-SOLV-G | Vul-Con™ Cleaning Solvent Gallon | 1 Gallon | Can | 3.6 | 8.0 |

Part Numbers

Vul-Con™ Breaker Fabric (Skimmed) is a specially formulated Leno Weave RFL treated fabric skimmed with uncured rubber for hot vulcanized belt splicing reinforcement. It is designed for use in step splicing and finger splicing of standard grade fabric belts

Vul-Con™ Breaker Fabric (Skimmed) is a specially formulated Leno Weave RFL treated fabric skimmed with uncured rubber for hot vulcanized belt splicing reinforcement. It is designed for use in step splicing and finger splicing of standard grade fabric belts

| Part Number | Description | Dimensions | U/M | Weight Lbs. kg | Weight Lbs. lbs |

|---|---|---|---|---|---|

| ASG-VC-BF-SK | Vul-Con™ Breaker Fabric (Skimmed) | 39” x 33’ | Roll | 19.0 | 41.90 |