ASGCO Wash Box™ Solves Severe Carry-back Problem at a Major…

Read More >WORKS ON THE RETURN SIDE OF THE CONVEYOR BELT

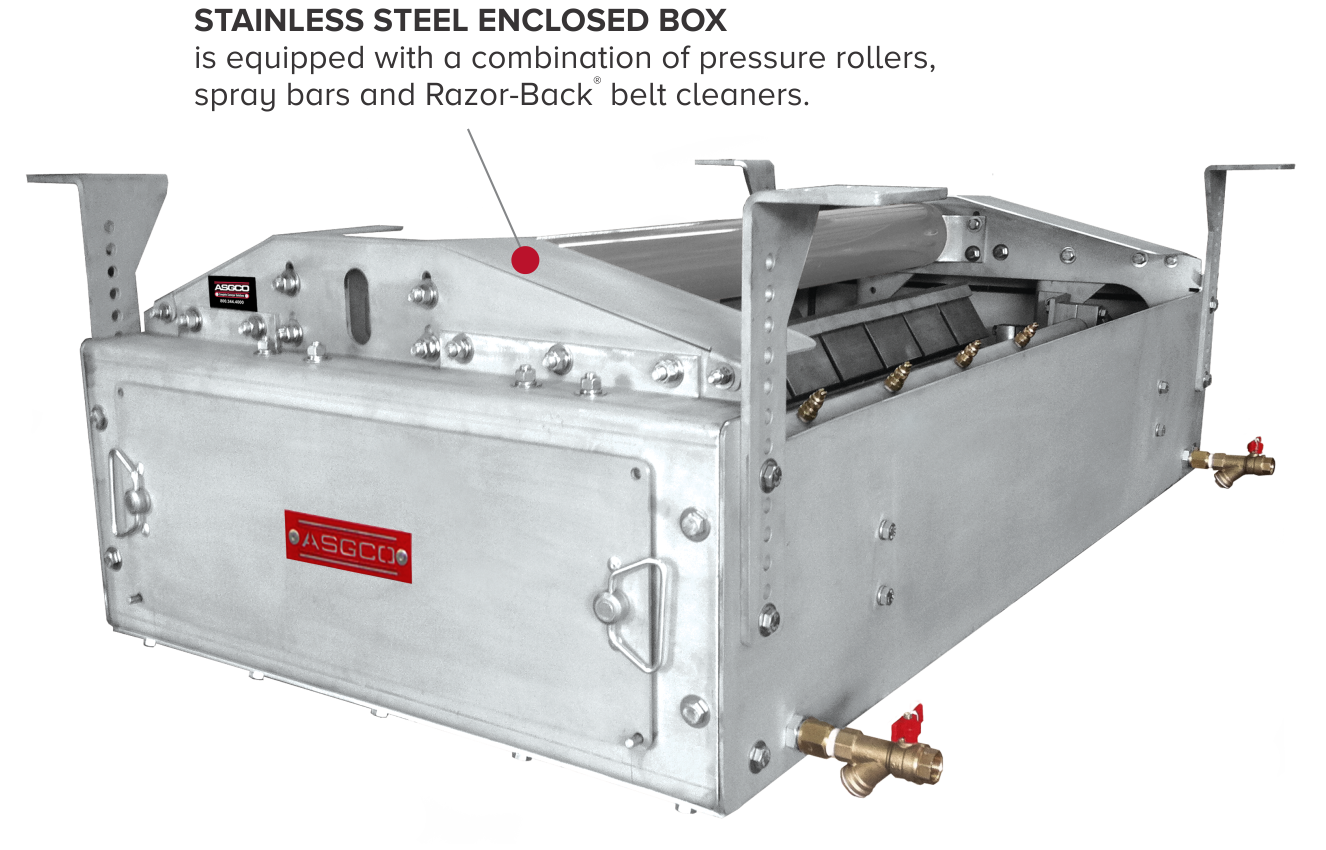

Design Features

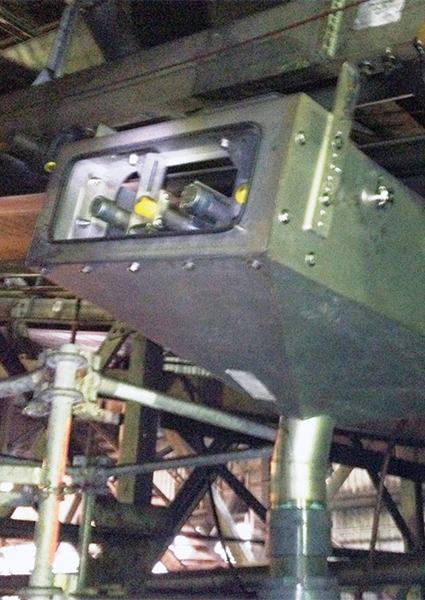

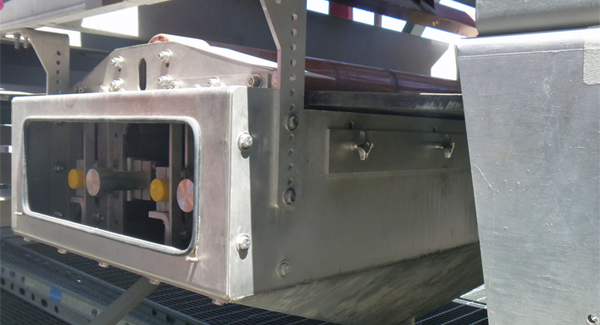

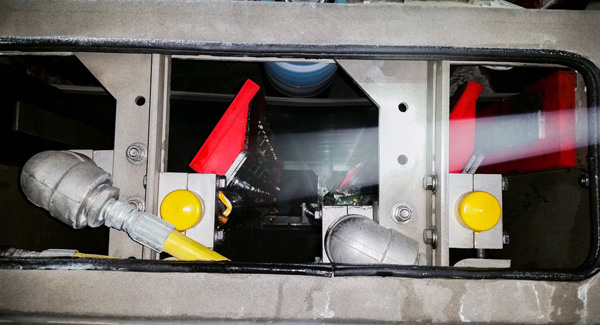

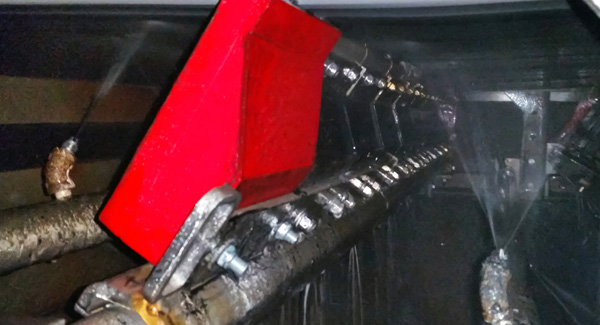

- Fully Enclosed – the Wash Box™ system provides excellent cleaning while containing the wash waste fluid.

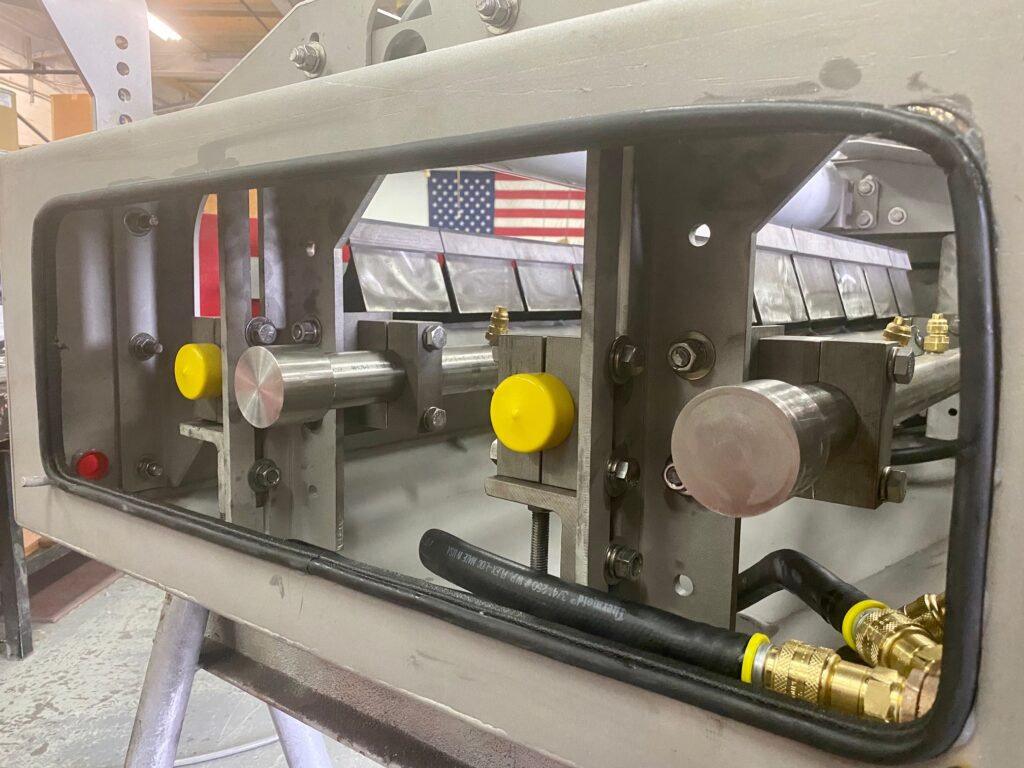

- Removable Inspection and Service Door – on each side, with wash down hose included.

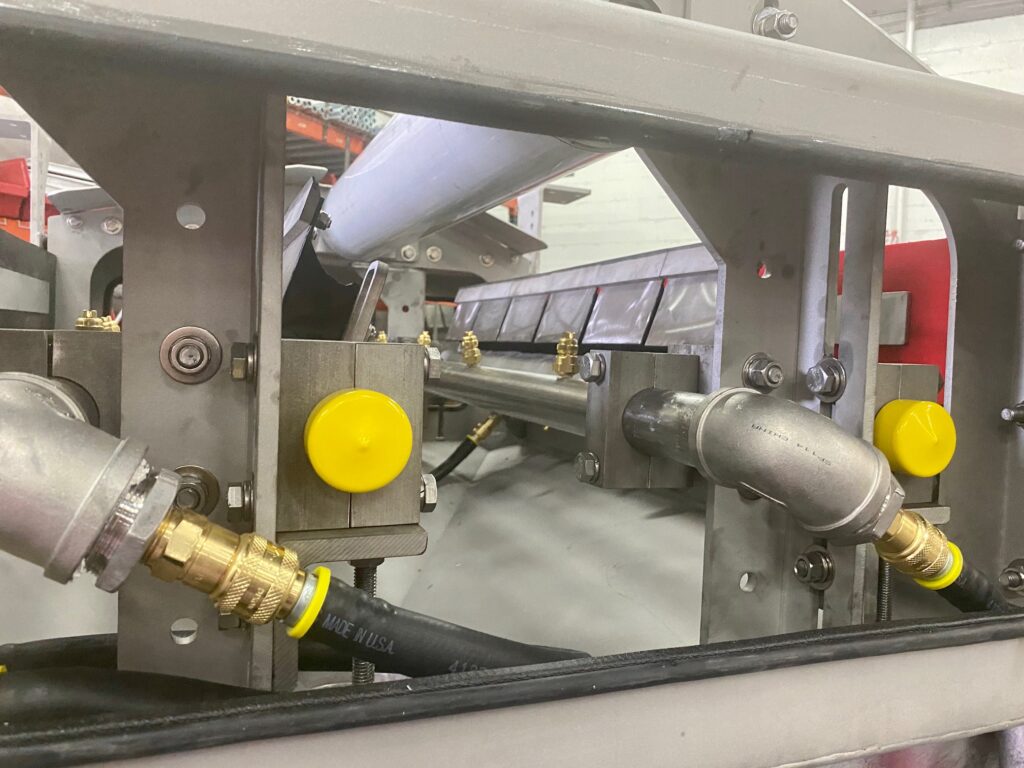

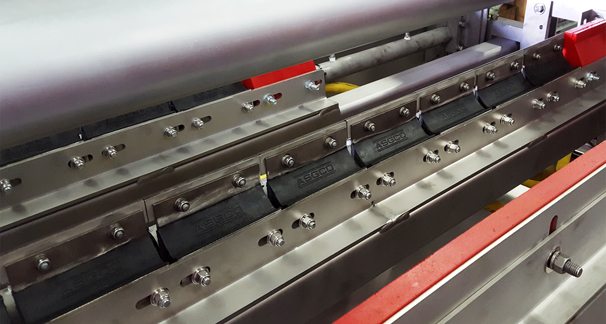

- Dual Sets of Razor-Back® Secondary Cleaners – and dry wipe.

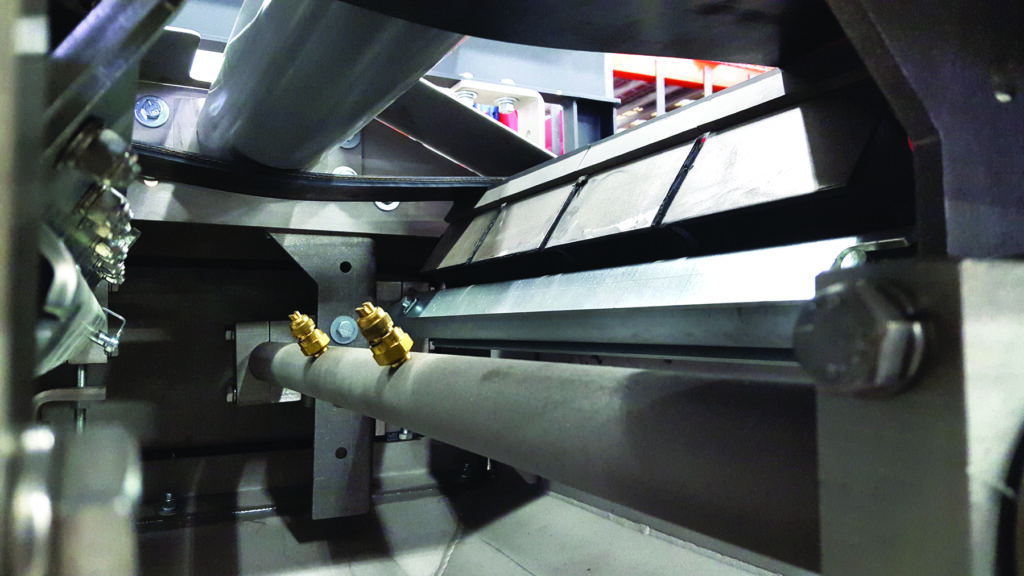

- Two Spray Bars, Nozzles and Valves – soften the carry-back and provides gentle cleaning.

- Equal Pressure – Snub Idler provides equal pressure on both Razor-Back® cleaners.

- 6” NPT Drain Pipe

- Available in – Stainless Steel, Galvanized and Powder Coated. Each steel enclosed box is equipped with a combination of pressure rollers, spray bars and Razor-Back® belt cleaners.

Part Numbers

ASGCO® Wash Box™ Stainless Steel

| Part Number | Belt Width in. | Belt Width mm. | Weight lbs |

|---|---|---|---|

| M-ASG-WB-24-SYS-SS | 24 | 600 | 438 |

| M-ASG-WB-30-SYS-SS | 30 | 750 | 548 |

| M-ASG-WB-36-SYS-SS | 36 | 900 | 658 |

| M-ASG-WB-42-SYS-SS | 42 | 1070 | 766 |

| M-ASG-WB-48-SYS-SS | 48 | 1200 | 876 |

| M-ASG-WB-54-SYS-SS | 54 | 1350 | 986 |

| M-ASG-WB-60-SYS-SS | 60 | 1500 | 1095 |

| M-ASG-WB-72-SYS-SS | 72 | 1800 | 1314 |

| M-ASG-WB-78-SYS-SS | 78 | 1950 | 1423 |

| M-ASG-WB-84-SYS-SS | 84 | 2100 | 1532 |

Solutions Case Studies

ASGCO Wash Box Solves Severe Carry-back Problem at a Major…

Read More >