PULP / PAPER / BIOFUEL INFORMATION

The pulp and paper industry comprises companies that use wood as raw material and produce pulp, paper, board and other cellulose-based products.

Paper derives from the word “papyrus”. Today, paper includes a wide range of products with very different applications: communication, cultural, educational, artistic, hygienic, and sanitary as well as storage and transport of all kinds of goods. It’s almost impossible to imagine a life without paper.

How many tons are used each year?

Every year, Americans use more than 90 million short tons of paper and paperboard. That’s an average of 700 pounds of paper products per person each year. Every year in America, more than 2 billion books, 350 million magazines, and 24 billion newspapers are published.

As one of the largest industrial sectors in the world, the pulp and paper industry has an enormous influence on global forests. This sector, which includes products such as office and catalog paper, glossy paper, tissue and paper-based packaging, uses over 40 percent of all industrial wood traded globally. And, the U.S. is still one of the world’s largest paper consumers.

The global pulp and paper industry consists of about 5000 industrial pulp and paper mills, and an equal number of very small companies. Broadly, the industry can be classified into two segments:

- Paper and paperboard (writing, printing, packaging and tissue). The writing and printing paper market can be further divided into coated and uncoated segments.

- Newsprint mainly uses for newspapers, flyers and other printed material intended for mass distribution.

What is a Pulp Mill?

A pulp mill is a manufacturing facility that converts wood chips or other plant fiber source into a thick fiber board which can be shipped to a paper mill for further processing. Pulp can be manufactured using mechanical, semi-chemical or fully chemical methods (kraft and sulphite processes).

Responsible pulp and paper operations can bring many benefits to forests, local economies and people, particularly in rural areas. Many pulp and paper companies are demonstrating leadership in responsible forestry and plantation management as well as in clean manufacturing processes and recycled content. And, U.S. consumers can play a key role in driving responsible forestry through their paper choices.

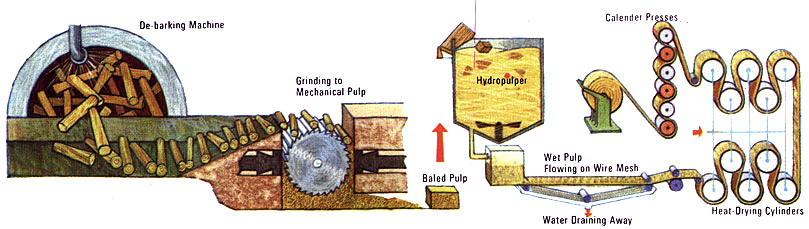

The pulping process

Trees provide the primary raw material for the paper and board industry. Wood is made from cellulose fibers that are bound together by a material called lignin. In a pulp mill, the fibers are separated from one another into a mass of individual fibers. After separation, the fibers are washed and screened to remove any remaining fiberbundles. The pulp may then be used directly to make unbleached papers, or bleached for white papers. Pulp may be fed directly to a paper machine in an “integrated paper mill” or dried and pressed into bales to be used as a raw material by paper mills worldwide.

Pulping, the wood chips are cooked in a digester with chemicals. Cooking removes lignin, breaking up the wood into fibers. The process results in slurry where fibers are loose but intact and have maintained their strength.

Bleaching

Most chemical pulp is made by the alkaline kraft or sulphate process which uses caustic soda and sodium sulphate to “cook” the wood chips. In the unbleached stage, a dark brown, but very strong pulp results which can be bleached to a high brightness if required. The cooking chemicals are recovered back to the process through evaporation and burning plants. Cooked pulp is washed and screened to achieve more uniform quality.

Finally the pulp is bleached (in 4-7 stages). Quality papers require a pulp which does not discolor during storage or go yellow when exposed to sunlight, and which retains its strength. Bleaching achieves all three requirements, and has the additional advantage of improving absorption capacity, removing any small pieces of bark or wood left behind as well as giving a high level of purity.

Production

Paper and board production involves two steps. First, the fibres need to be produced. This is done in a pulp mill where pulp is produced using chemical or mechanical processes. Pulp production can be integrated with paper production, or produced in a separate pulp mill. The paper itself is then produced on a paper machine from a mixture of fibres (which can be virgin or recovered fibres), chemicals and additives.

Each paper or board grade is produced on equipment tailored for this particular grade and mill. Tissue machines producing toilet or napkin paper, or paperboard production differ considerably from the newsprint production process and newsprint paper machine. Production processes are optimized for each grade. There are many variables: raw material composition (mixture of chemical softwood and hardwood pulp, mechanical pulp, recovered paper, fillers, pigments, additives, etc.), machine size (width, speed), type of production equipment, and automation level.