Challenge: This sand and gravel plant was experiencing massive build-ups of carry back.

The challenge was to be able to install a conveyor belt pre-cleaner that could eliminate

the carry-back and provide better cleaning efficiency in an extremely limited space.

Manual excavation everyday with continuous high pressure water on the ground was being

used to prevent the build up. This process caused increased labor and housekeeping

problems and became very costly to the customer. Also the water on the floor surrounding

the conveyor was contaminating the product.

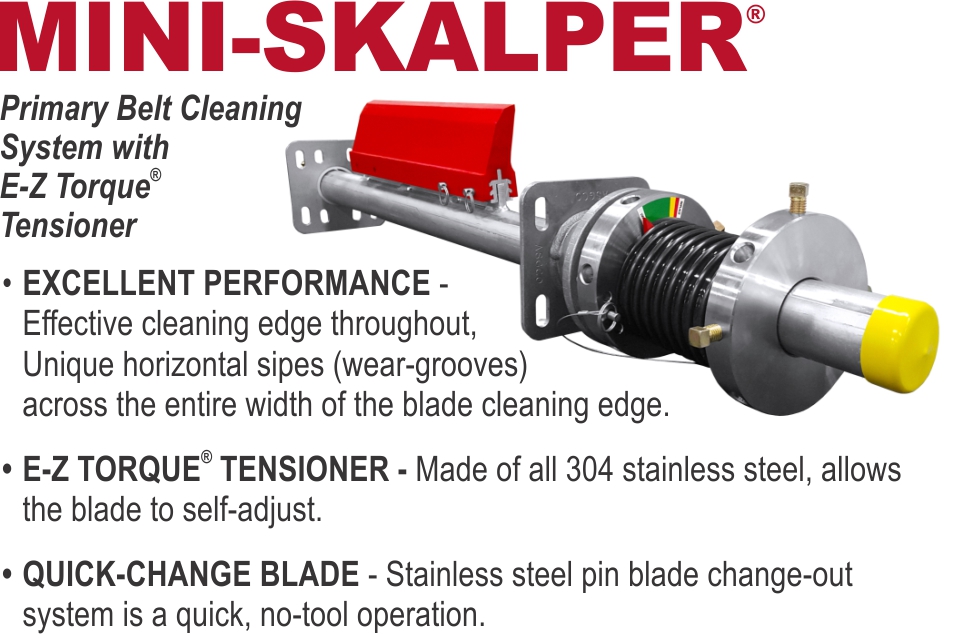

Solutions: To eliminate the carry-back problem within the limited space, the recommendation

was to install ASGCO®’s Mini-Skalper® IV system with E-Z Torque® Tensioner.

This pre-cleaner is designed for small diameter pulleys where space and size is a factor.

ASGCO®’s Mini-Skalper® IV system is ideal in situations where the head pulley is

less then 16” (400mm) in diameter or tight locations.

Results: After installation of the ASGCO® Mini-Skalper® IV pre-cleaner,

the need for continuous high pressure cleaning was eliminated.

Clean up is now reduced to once every other week. The belt operates

much more efficiently, spillage has been virtually eliminated, and the

lifespan of the belt will increase dramatically. This plant now

experiences much less downtime, requires far less clean up and

promotes a much safer working environment for its employees.