ASGCO® Troughing Tru-Trainer® conveyor belt tracking system solves belt tracking problems for aggregate facility processing crushed stone.

[line]

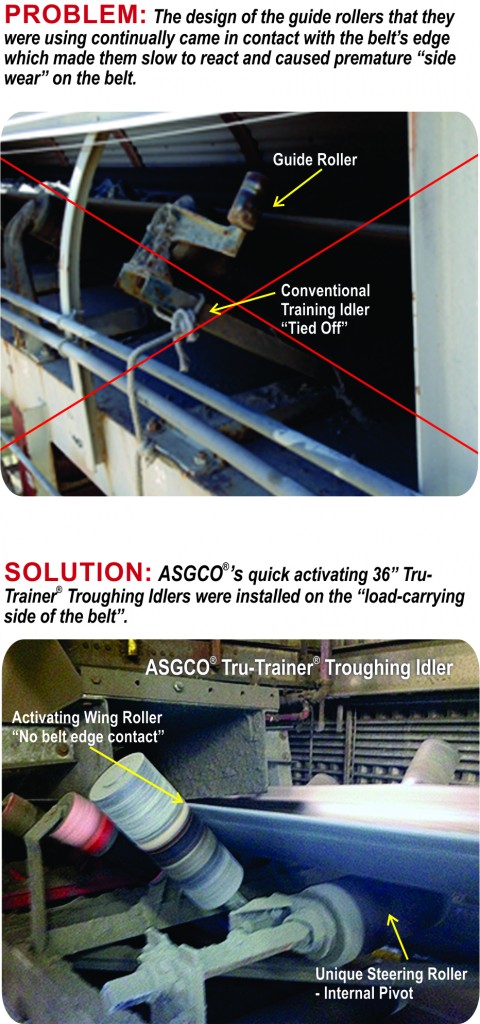

Problem:

This aggregate facility was processing crushed stone. (800 TPH / Belt Speed: 550 FPM)

They were using conventional guide roller trackers that kept failing. Due to the design

of the guide rollers they continually came in contact with the belt’s edge which made

them slow to react and caused premature “side wear” on the belt. The operators were prone

to “tying the guide rolls off” which eliminated “the ability for it to train/align the belt”.

Also “build-up” of carry-back on the external pivot caused freeze-up (stop working) making

it vulnerable to the elements of the harsh environment.

Solutions:

To solve the problem we needed to provide a belt tracking idler that reacted quicker without freezingup or causing belt damage in the harsh environment. ASGCO® 36” Tru-Trainer® Troughing Idlers were installed prior to where the problem of misalignment occurred on the “load-carrying side of the belt”. Conventional training devices utilize “guide rolls” that cause premature belt wear and are slow to react to belt mistracking. At no time does the ASGCO® Troughing Tru-Trainer wing’s contacts the belt’s edge.

ASGCO®’s Tru-Trainer® Troughing Idler’s unique center roller does all the belt’s steering. It’s quicker to react than conventional trainers with guide rolls. The internal sealed pivot was protected from the harsh elements and fugitive build-up which caused the other conventional guide roller pivots to “freeze up” and not perform. ASGCO®’s Tru-Trainer® Troughing Idler’s superior belt tracking performance is saving the mine money due to less spillage, less downtime and less belt wear.

[line]

Tru-Trainer® Troughing Idler

The Tru-Trainer® Troughing Idler is based on an enhanced load carrying design which features

quicker activation, increased swing and overall better performance. There is no edge damage

and the troughing angle is now adjustable.

• Load Carrying Side Conveyor Alignment – The Tru-Trainer® Troughing

roller was  specifically developed to accommodate a different training configuration.

specifically developed to accommodate a different training configuration.

• Activating Wing Rollers – are set to have a maximum effective contact

between the belt edge and the wing roller of 25°-55°

• Internal Pivot – The Tru-Trainer® Troughing Idler pivots on its internal

pivot and steers the conveyor belt back to center with minimum force.

• Unique Steering Roller – the center roll, where the most effective

steering forces are exerted, does all the steering and not the wing rolls.