Current recycling disposal laws make it more important than ever to offer comprehensive recycling programs to reduce landfill materials and increase post consumer recycled materials.

One recycling center was experiencing troublesome build-up on the return idlers causing multiple

problems for the conveyor system.

[line]

Problem:

Co-mingled materials traveling together along the conveyor to a sorting facility would constantly leave behind sticky deposits that would accumulate, requiring costly downtime and maintenance, especially on the return idlers and belt.

Solutions:

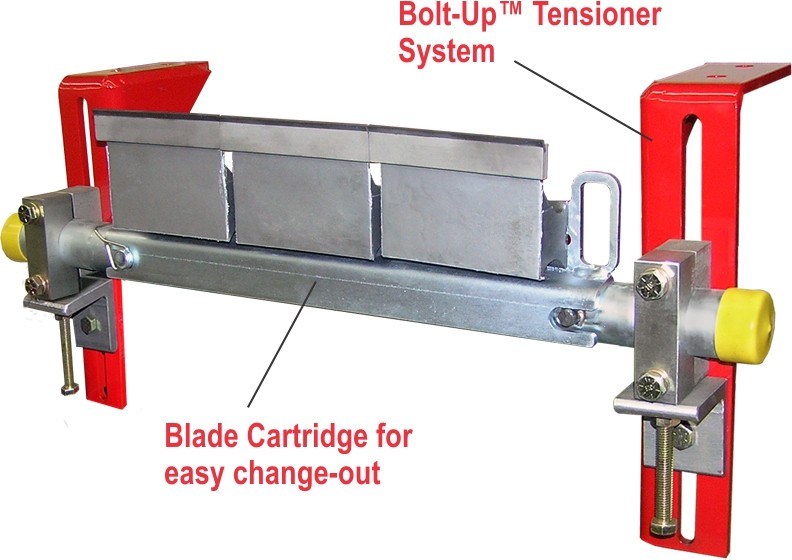

After surveying the conveyor system ASGCO® recommended installing a Razor-Back® secondary belt cleaning system. The Razor-Back® system can be installed typically were the conveyor belt leaves the head pulley on the return side of the conveyor belt. Due to the advanced design of the independent carbide blades on this system, the sticky residue was removed from the return side of the system before it could come in contact with the return idlers. This system virtually eliminated the carry-back problem and greatly reduced both maintenance costs and downtime.

As illustrated in the photos (right), it’s clear that the material residue is being effectively removed from the belt, and diminishing the possibility of fouling return idlers. The customer was so thoroughly impressed with the performance of the Razor-Back® secondary system that they will soon be adding additional systems to their plant.

[line]

Razor-Back® Secondary Belt Cleaner

The Razor-Back® belt cleaner features tough self-adjusting replaceable tungsten carbide blades (non-carbide also available)

for extremely effective conveyor belt cleaning.

- Longwearing Abrasion Resistant – tungsten carbide

blades provides and maintains

blades provides and maintains

a great cleaning edge against the conveyor belt. - Impact Absorbing Tension Cushions – tension each individual blade to the belt for

a controlled and effective conveyor belt cleaning across the entire width of the belt. - Compact Design – allows for an installation that requires less then 9” of clearance

to be installed and maintained.

Mechanical Splices? No Problem. The Razor-Back® can be installed on conveyor belts with mechanical splices, due to the laid-back wiping blade angle and impact-absorbing tensioning cushions, allowing the mechanical splices to pass without damaging the

belt cleaner or the splice.