Our fabrication capabilities are enhanced by incorporating precision machinery and advance software to the job process.

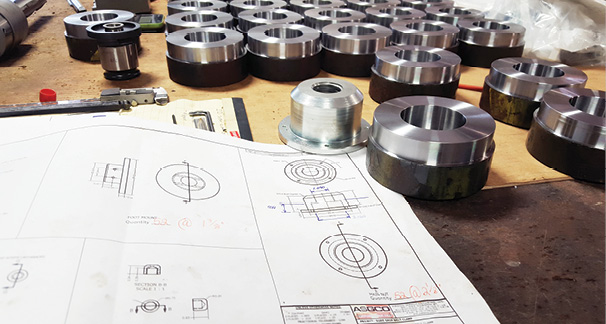

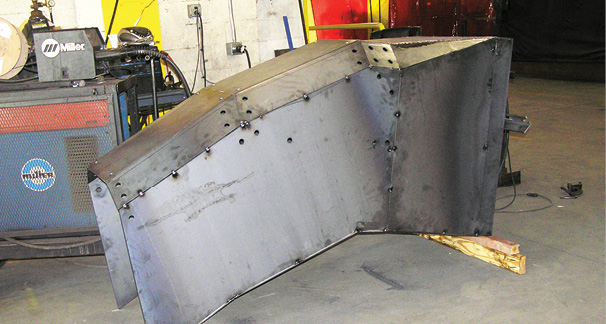

ASGCO® Steel Fabrication boasts 30,000 square feet of in-house Metal Fabrication and Machining. This work space allows us to provide custom quality-controlled components and assemblies that support the requirements of machine builds as well as enables us to deliver a fast turn-around time. We have extensive CNC laser and plasma cutting equipment, machining equipment, including CAD/CAM machinery for CNC milling, drilling, turning, and grinding operations on all types of metal and plastic materials. Our specialties lie in CNC horizontal turning, vertical 5-axis milling, horizontal milling, and high-speed machining. With those particular capabilities, we are able to precision machine parts from 1″ to 120″.

Our metal fabrication and machining teams know their trades and value quality, accuracy, and on-time completion of their work. Both teams work together to manufacture components integral to ASGCO®’s custom design build and build-to-print equipment, as well as provide job-shop machining and fabrication services for clients. ASGCO®’s in-house abilities demonstrate our full-service commitment to clients and ensure exceptional quality control of our manufactured components. For a full list of ASGCO®’s Steel Fabrication equipment and capabilities, see our Metal Fabrication and Machining equipment list below. b

Services and Capabilities

- Light to Heavy Fabrication

- Laser Cutting

- Precision Bending

- Plating

- Galvanizing

- Epoxy Coating

- Powder Coating

- Conveyors

- Chutes and Transfer Points

- Hoppers and Bins

- Stairways and Handrails

- Custom Fabricated parts

- Repairs

Operating Machines

- Trumpf 3000 Watt Laser

- Trumpf Tru Tops Nesting

- Komatsu Hi-Definition Plasma Table

- 2 Hyd-Mach Automatic Band Saws

- Mazak VTC30 Mil

- Victor Manual Milling Machine

- South Bend Manual Lathe

- Mazak ST35 Lathe

- Primline 220 Ton Press Break

- Miller TiG Welder

- 6 Miller P30 MIG Welders

- Paint Booth

- Powder Coating

Typical Projects include:

- Replacement of rusted/damaged conveyor structures.

- Complete Chute replacement and relining

- Impact Zone Modifications, Skirting installation and/or replacement

- Conveyor Frame replacement

Contact Us!

…to get a free quote on an upcoming steel fabrication job or project. We will gladly review the project, discuss shipping schedules and look for ways to reduce costs and increase efficiency.

Ron Depack,

Steel Fabrication Shop, Operations General Manager

rdepack@asgco.com