Challenge: This copper mining facility needed to remove the residual…

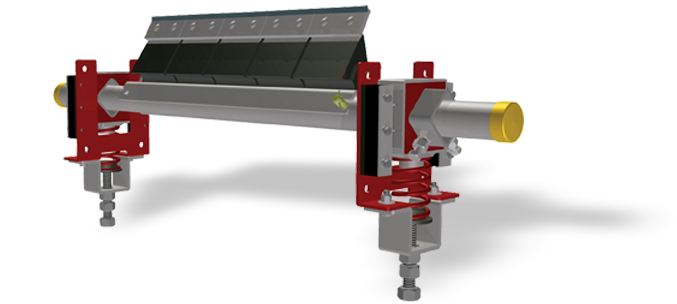

Read More >DEISGNED FOR HIGH SPEED & MAXIMUM TONNAGE

Design Features

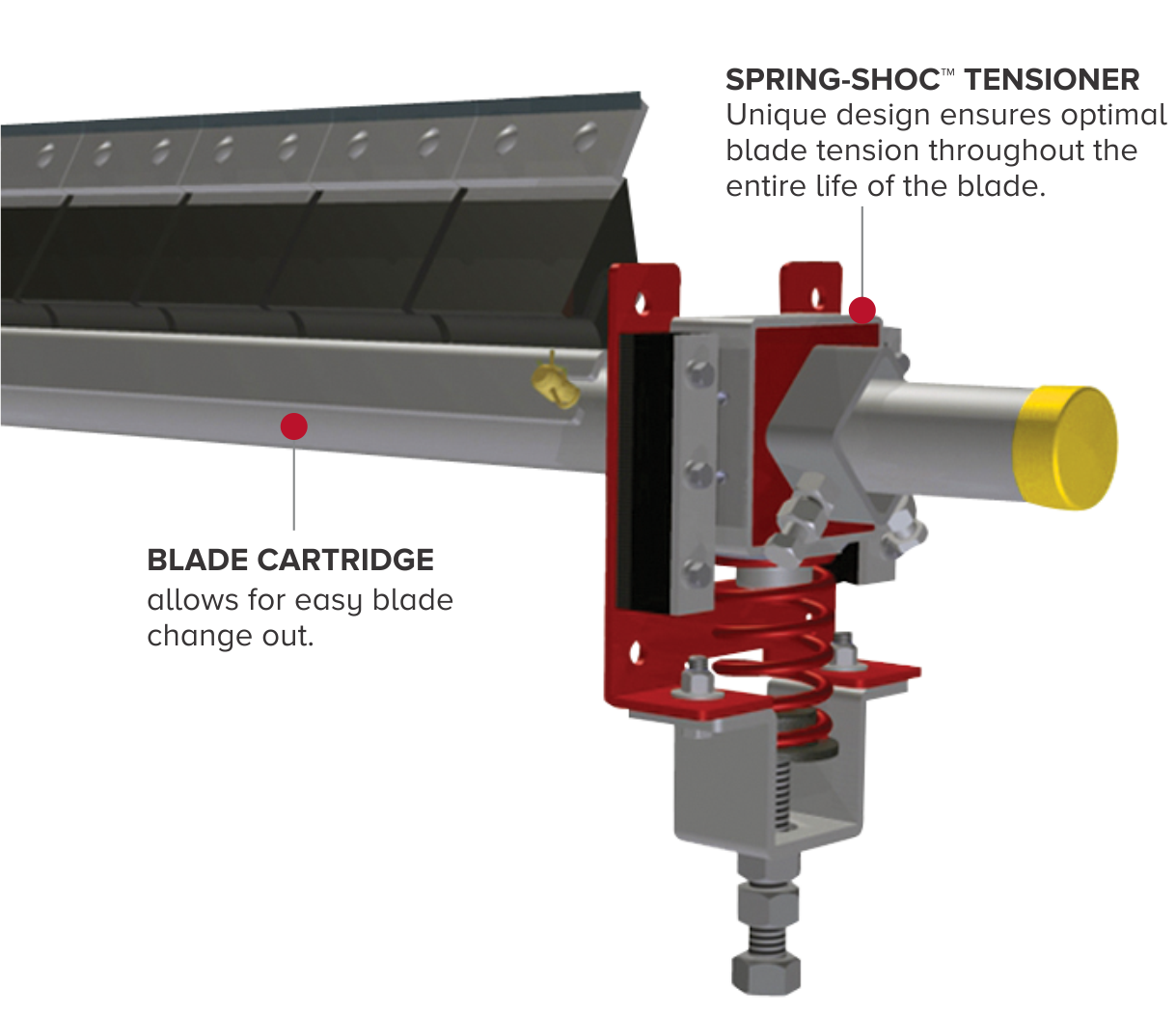

- Complete Cleaning – with our combination of cleaning blades specific for your application and dual tensioning action from our Spring-Shoc™ or Air-Shoc™ tensioner along with the impact absorbing rubber tensioning cushions and mounting system.

- Available with replaceable MDX™ V-Tips – for vulcanized conveyor belts or MDX® C-Tips for conveyor belts with mechanical fasteners.

- Quick-Change – slide-out mounting system allows for simple removal of the cleaning cartridge from either side of the conveyor, without having to remove mounting brackets or the main mounting tube.

- Designed – for the toughest of mining environments and conditions including underground and surface coal, hard rock, power plant and load-out facilities.

- Compatible and Safe – for mechanically or vulcanized spliced conveyor belts and its slide-out blade cartridge allows for improve safety by avoiding workers having to crawl into confined chute areas or underneath conveyor structures.

PRODUCT SPECIFICATIONS

Maximum Belt Speed – 1200 fpm (6.0 m/sec) Application – Underground Mining, Hard Rock Mining, Metals (copper/gold) Mining, Steel Mills, Iron Ore, Bulk Shipping Terminals, Coal Fired Power PlantsPart Numbers

Razor-Back® MDX with Sping-Shoc™ Tensioner

Substitute the asterisk (*) MDX C-Tip = C | MDX V-Tip = TC

Belt Speed: <1200 fpm <6m/sec / -20-400°F -28 to 204°C

| Part Number | Belt Width in. | Belt Width mm | Weight lbs |

|---|---|---|---|

| M-RB*MDX-SYS-48-ST | 48 | 1200 | 167 |

| M-RB*MDX-SYS-54-ST | 54 | 1350 | 179 |

| M-RB*MDX-SYS-60-ST | 60 | 1500 | 192 |

| M-RB*MDX-SYS-72-ST | 72 | 1800 | 204 |

| M-RB*MDX-SYS-84-ST | 84 | 2100 | 242 |

| M-RB*MDX-SYS-96-ST | 96 | 2400 | 266 |

Part Numbers

Razor-Back® MDX with Air-Shoc™ Tensioner

Substitute the asterisk (*) C-Tip = C | V-Tip = TC

Belt Speed: <1200 fpm <6m/sec / -20-400°F -28 to 204°C

| Part Number | BELT WIDTH IN. | BELT WIDTH MM. | WEIGHT LBS |

|---|---|---|---|

| M-RB*MDX-SYS-48-AS | 48 | 12 | 170 |

| M-RB*MDX-SYS-54-AS | 54 | 1350 | 182 |

| M-RB*MDX-SYS-60-AS | 60 | 1500 | 195 |

| M-RB*MDX-SYS-66-AS | 66 | 1600 | 207 |

| M-RB*MDX-SYS-72-AS | 72 | 1800 | 220 |

| M-RB*MDX-SYS-84-AS | 84 | 2100 | 244 |

| M-RB*MDX-SYS-96-AS | 96 | 2400 | 268 |

Literature Downloads

Solutions Case Studies

Challenge: The cleaners previously installed on the belt head were…

Read More >