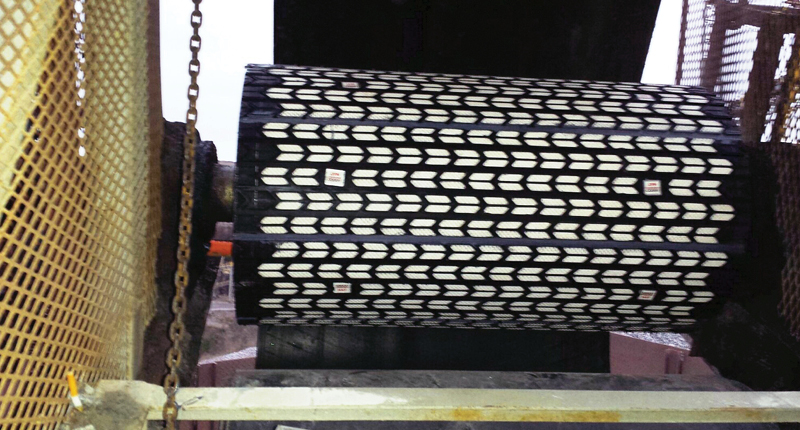

CORRECTS BELT SLIPPAGE AND PREMATURE WEAR

Design Features

- MSHA approved for mine use – meets all requirements for flame-resistant solid products taken into mines. Acceptance Marking No. MSHA IC -174/2

- Increase Productivity – by delivering increased traction between the conveyor belt and pulley, allows for lower belt tension than with rubber lagging.

- Improved Conveyor Belt Tracking – due to the Arrowhead patterns self-cleaning ability, which reduces the material build-up and thereby eliminates the major source of conveyor belt misalignment.

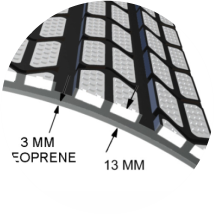

- Bonding Strength – that is superior to others, due to 3mm of our neoprene compound vulcanized into the bottom-side of the lagging.

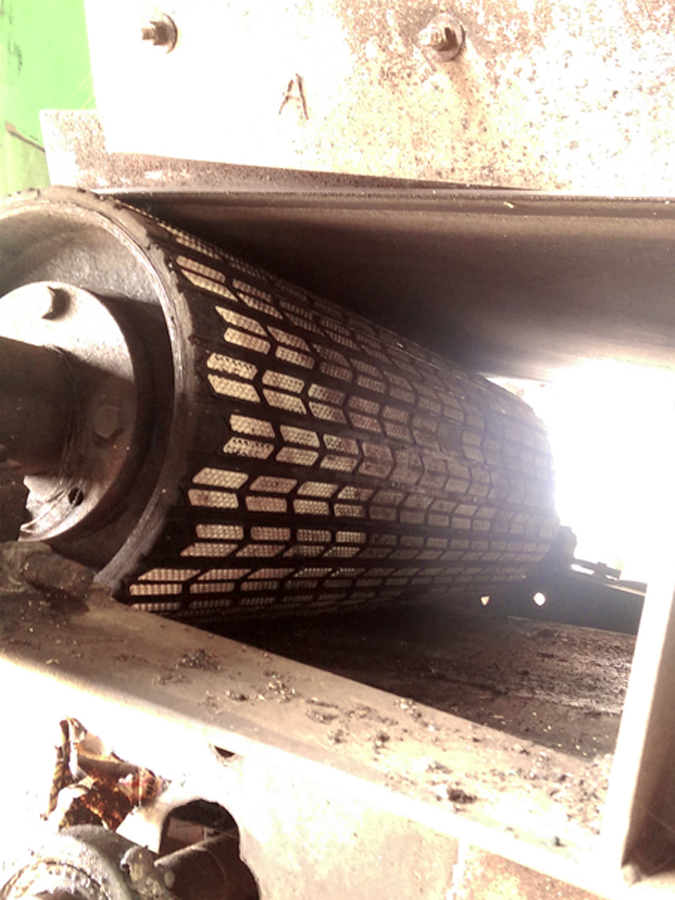

- Superior Wear – ability in abrasive or highly wet or dry applications as seen in below ground and above ground mining.

- Easy Installation – can be done in place, on the plant site, at your local distributor or at the pulley manufacturer. Each strip is 10” (250mm) wide x pulley face (see chart).

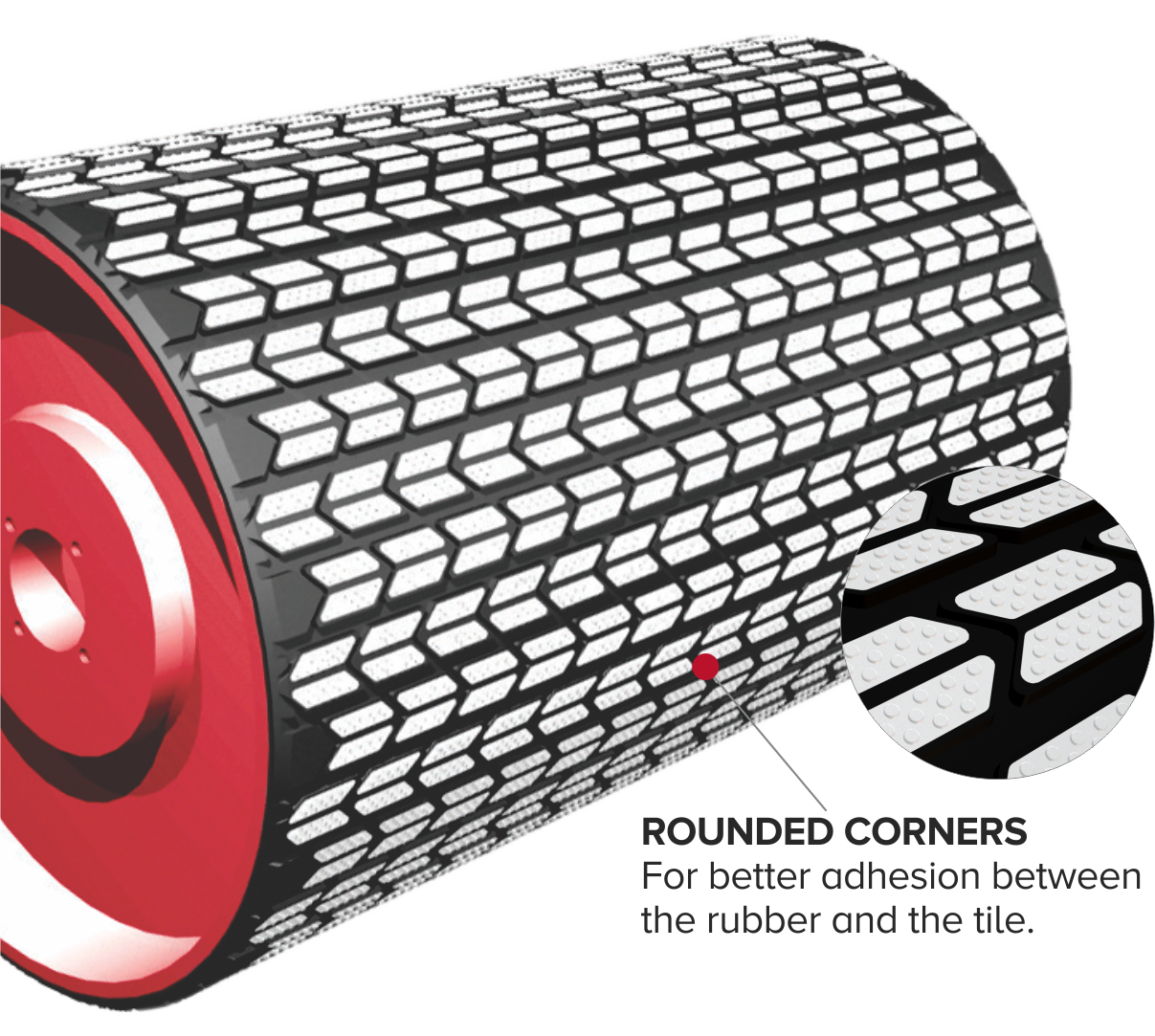

- Tile – fully enclosed by rubber with rounded corners to allow for better adhesion between the rubber and the tile.

- Available – in 5/8”and 1” thicknesses in both SBR and MSHA grade rubber compounds.

PRODUCT SPECIFICATIONS

Available – 5/8” and 1” thicknesses in both SBR and MSHA grade rubber compoundsPart Numbers

Arrowhead™ NAT Ceramic Drive

| Part Number | Belt Width in. | Belt Width mm. | Thickness | Inches Ceramic | Inches Rubber | Weight lbs |

|---|---|---|---|---|---|---|

| ASG-10X24-CL | 24 | 600 | 1/2" | 24-7/8" | 39-1/2" | 9 |

| ASG-10X30-CL | 30 | 750 | 1/2" | 31-1/4" | 47" | 11 |

| ASG-10X36-CL | 36 | 900 | 1/2" | 36-1/4" | 51-1/2" | 13 |

| ASG-10X42-CL | 42 | 1050 | 1/2" | 41-1/8" | 56-1/2" | 15 |

| ASG-10X48-CL | 48 | 1200 | 1/2" | 48-1/2" | 64-1/2" | 17 |

| ASG-10X54-CL | 54 | 1350 | 1/2" | 55-7/8" | 71-1/4" | 19 |

| ASG-10X60-CL | 60 | 1500 | 1/2" | 60-3/4" | 76" | 21 |

| ASG-10X72-CL | 72 | 1800 | 1/2" | 73-1/8" | 89" | 23 |

| ASG-10X84-CL | 84 | 2100 | 1/2" | 83-1/8" | 99" | 33 |

Part Numbers

Arrowhead™ MSHA Ceramic Drive

| Part Number | Belt Width in. | Blade Width mm. | Thickness | Inches Ceramic | Inches Rubber | Weight lbs |

|---|---|---|---|---|---|---|

| ASG-10X24-MSHA-CL | 24 | 600 | 1/2" | 24.41 | 47.24 | 9 |

| ASG-10X30-MSHA-CL | 30 | 750 | 1/2" | 30.71 | 53.15 | 11 |

| ASG-10X36-MSHA-CL | 36 | 900 | 1/2" | 37.01 | 59.06 | 13 |

| ASG-10X42-MSHA-CL | 42 | 1050 | 1/2" | 43.31 | 64.96 | 15 |

| ASG-10X48-MSHA-CL | 48 | 1200 | 1/2" | 47.24 | 70.87 | 17 |

| ASG-10X54-MSHA-CL | 54 | 1350 | 1/2" | 56.69 | 78.74 | 19 |

| ASG-10X60-MSHA-CL | 60 | 1500 | 1/2" | 62.99 | 86.61 | 21 |

| ASG-10X72-MSHA-CL | 72 | 1800 | 1/2" | 72.83 | 94.49 | 23 |

| ASG-10X84-MSHA-CL | 84 | 2100 | 1/2" | 84 | 101 | 30 |

| ASG-1-10X60-MSHA-CL-1 | 60 | 1500 | 1" | 62.99 | 56.61 | 21 |

| ASG-1-10X72-MSHA-CL-1 | 72 | 1800 | 1" | 72.83 | 94.49 | 23 |

| ASG-1-10X84-MSHA-CL-1 | 84 | 2100 | 1" | 82.09 | 102.36 | 25 |