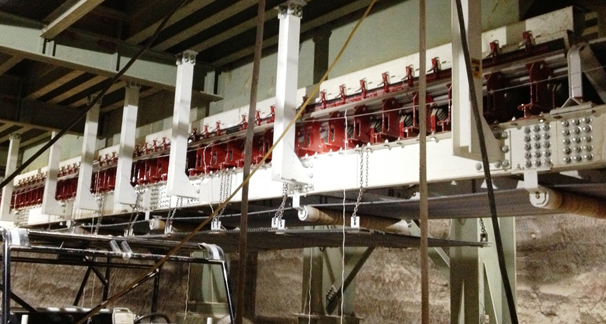

THE ULTIMATE IN LOADING ZONE SPILLAGE CONTROL

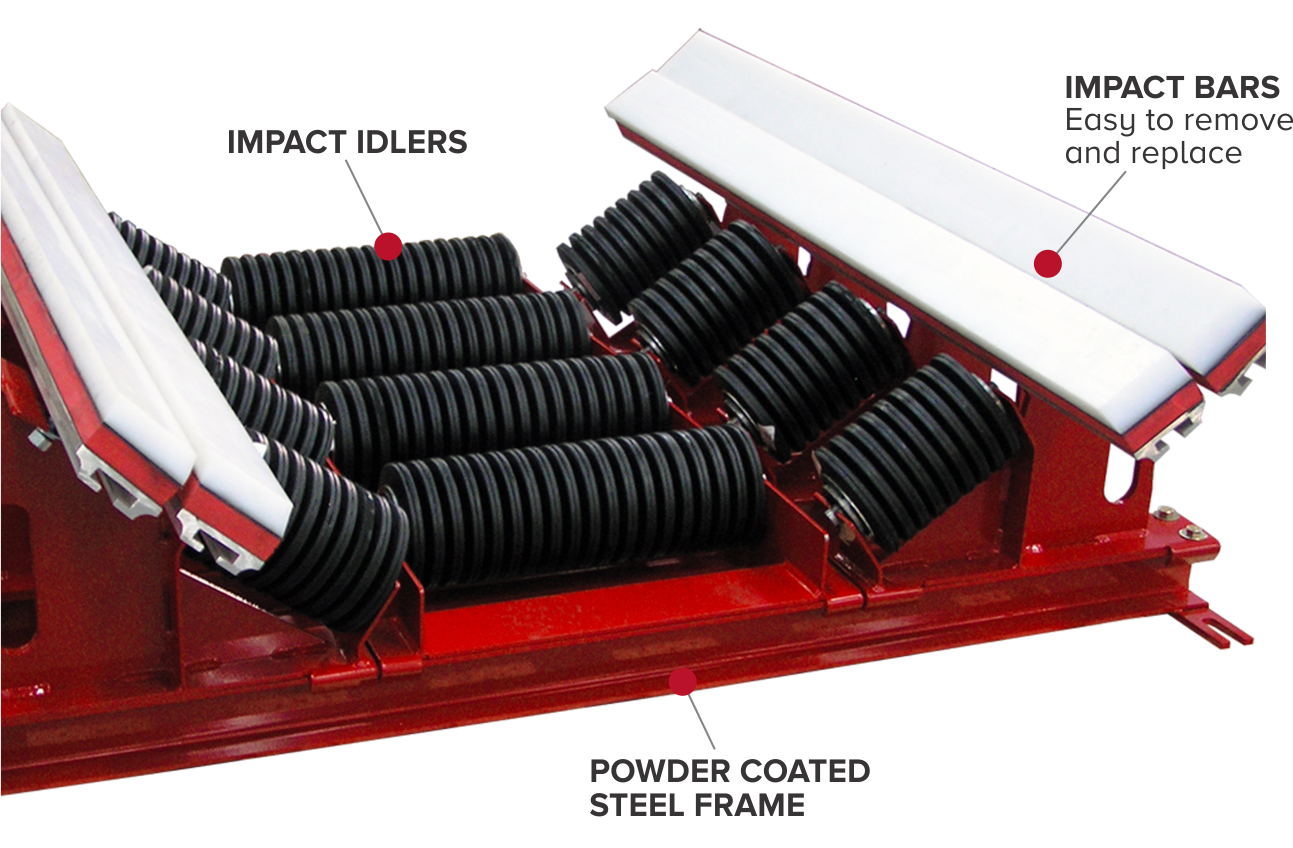

Design Features

- Specifically Designed – for wide, hi-speed (over 700 fpm), and high tonnage conveyor systems.

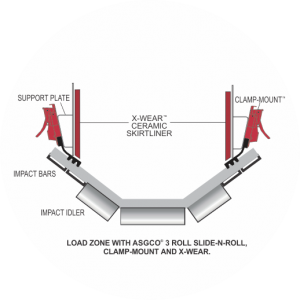

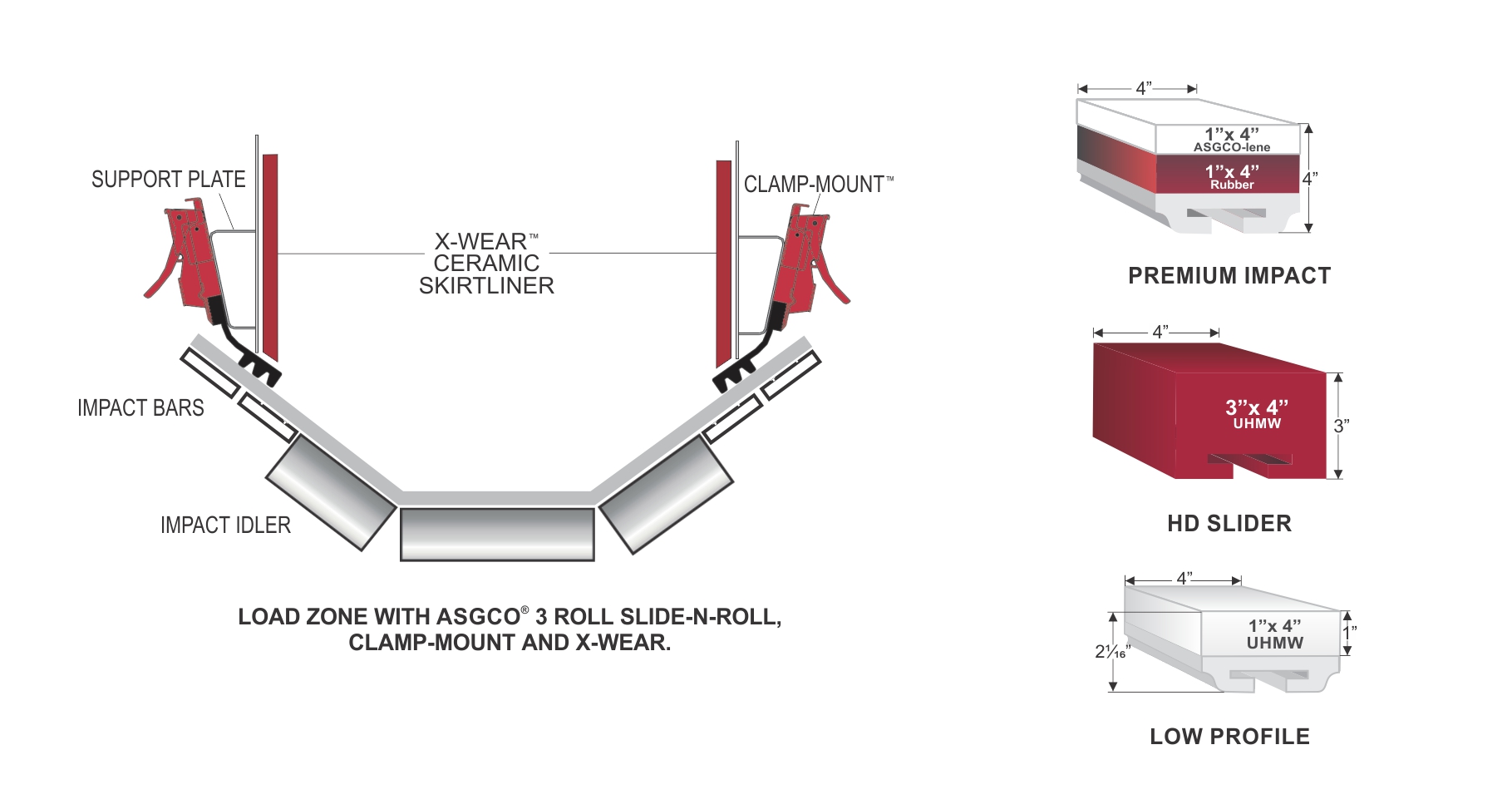

- Reduces Dust – by maintaining a flat area in the load zone for the skirting to maintain an effective seal against the conveyor belt.

- Robust Design – for the toughest applications in the material handling industry.

- Custom Built – beds can be made into 4’(1200mm), 5′ (1500mm), 6′ (1800mm) or into our 10′ (3m) standard length bed with frames on 12” centers.

Product Specifications

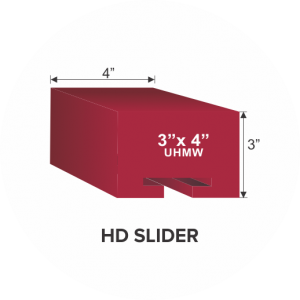

Maximum Belt Speed – 1000 fpm (5.0 m/sec) Applications – Bulk Shipping Material, Cement, Wood Processing, Aggregate and Mineral (Potash, Salt) Mining Impact Bars – are available in standard, HD and Premium in 2’, 4’ or 5’ length. Trough Angle – available in 20°, 35° and 45°Part Numbers

This is a custom ASGCO® product, for more information contact us.