ELIMINATE MATERIAL ACCUMULATION AND DUST

FEATURES & BENEFITS

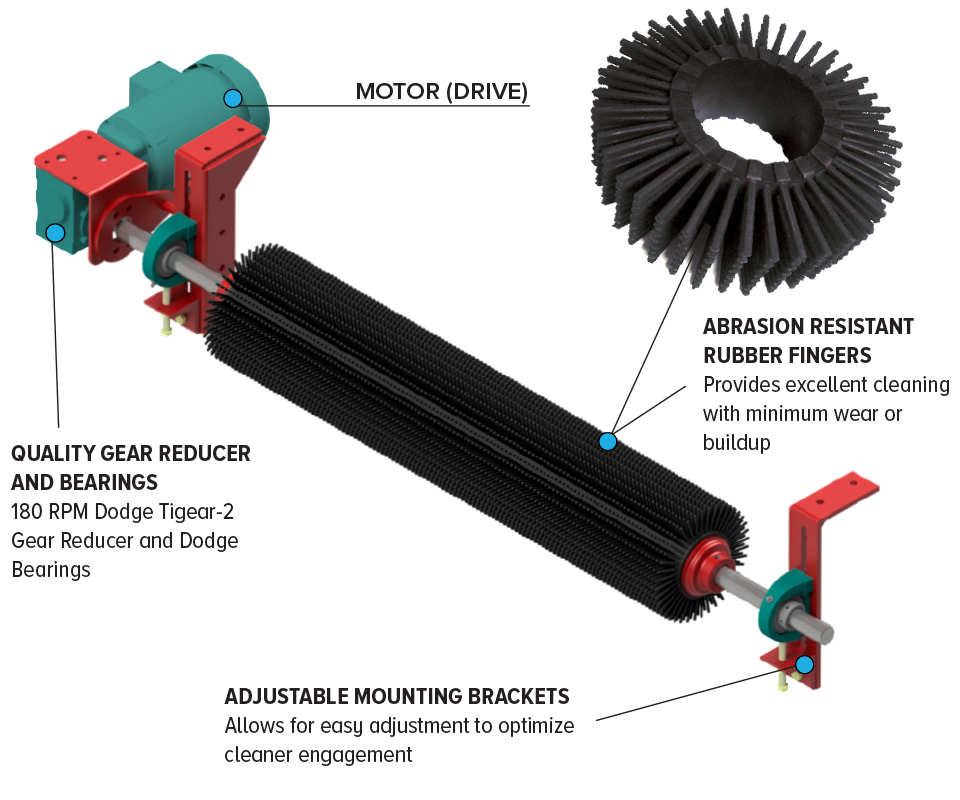

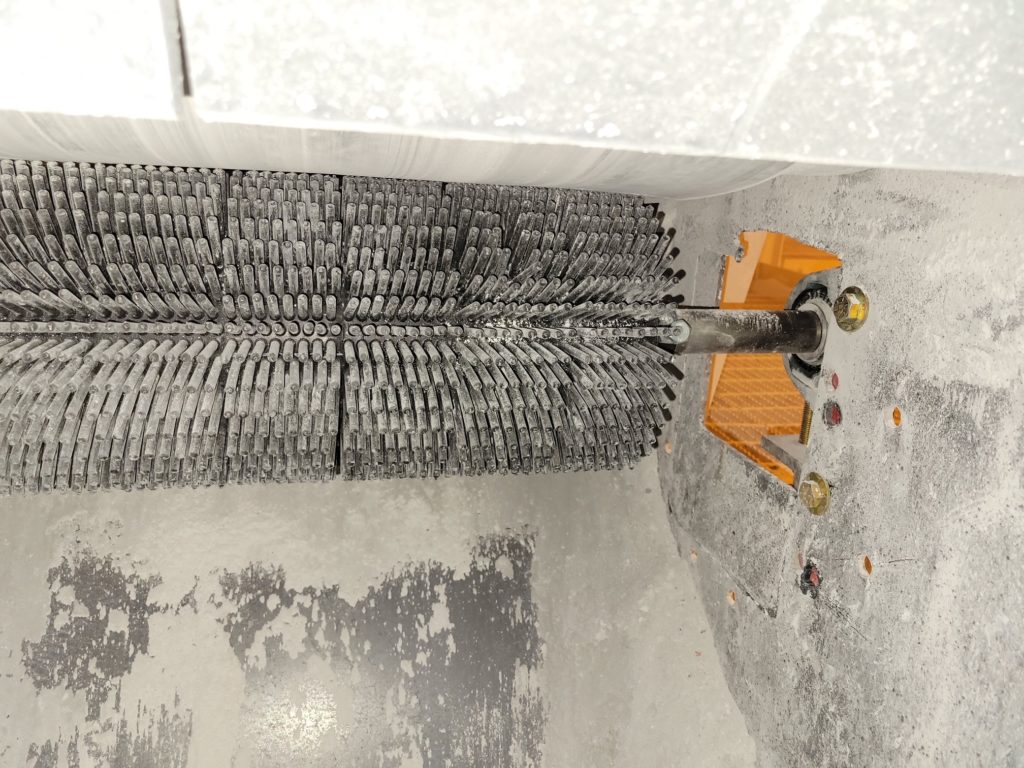

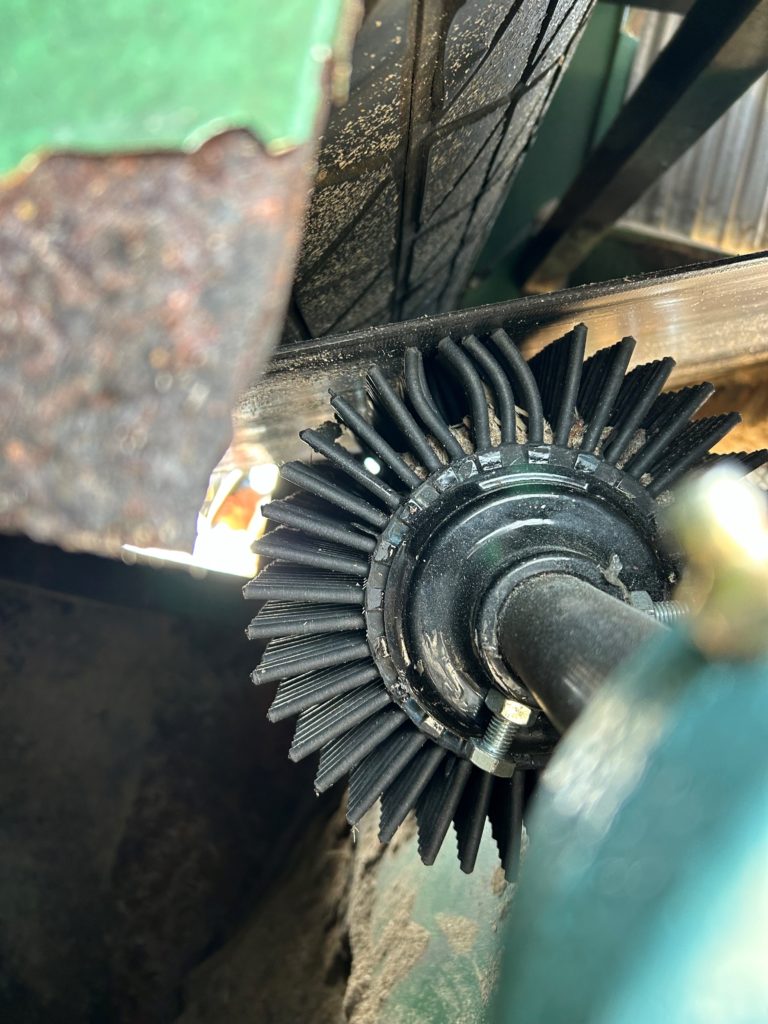

- Excellent Cleaning – Abrasion resistant rubber fingers spin in the opposite direction of the conveyor belt efficiently removing any materials that adhere to the belt surface, reducing carry-back and housekeeping issues.

- Reduces Maintenance Costs – The motorized brush system reduces carryback, which results in lower cleanup costs and less unplanned downtime.

- Robust and Versatile Design – The safe design of the system eliminates v-belts, requires minimal space to install and is easy to adjust. It can be used on mechanically spliced or vulcanized conveyor belts, as well smooth, chevron, ribbed or cleated belts.

PRODUCT SPECIFICATIONS

- Maximum Belt Speed – 700 fpm (3.5 m/sec)

- Temperature Rating: –20°F to 180° F (-30° C to 82° C)

- CEMA Cleaner Rating: Class 4

- Overall Brush Diameter: 9” (230mm)

- Bristle Material: SBR

- Bristle Length: 2” (50mm)

- Brush RPM: 180

- Shaft Diameter: 1 1/2” (38mm)

- Motor Voltage and HP Options:

- 208-230/460VAC 3 Phase*: 1HP (Cleaners 18-84”)(450mm-2150mm)

- 110/220VAC Single Phase*: 1HP (Cleaners 18-84”)(450mm-2150mm)

- 575V 3 Phase*: 1HP (Cleaners 18–84”)(450mm-2150mm) *other motors available upon request

- Available for Belt Widths: 18” to 84” (450 to 2100mm)

- Horizontal Clearance Required: 12” (305mm)

Part Numbers

Brush Cleaner Non-Motorized System

| Part Number | Belt Width In. | Belt Width mm. | Brush Diameter | Shaft | Weight lbs |

|---|---|---|---|---|---|

| M-ASG-RBC-24-NM | 24 | 600 | 8" | 1" | 0 |

| M-ASG-RBC-30-NM | 30 | 750 | 8" | 1" | 0 |

| M-ASG-RBC-36-NM | 36 | 900 | 8" | 1" | 0 |

| M-ASG-RBC-42-NM | 42 | 1050 | 8" | 1" | 0 |

| M-ASG-RBC-48-NM | 48 | 1200 | 8" | 1.5" | 0 |

| M-ASG-RBC-54-NM | 54 | 1350 | 8" | 1.5" | 0 |

| M-ASG-RBC-60-NM | 60 | 1500 | 8" | 1.5" | 0 |

Part Numbers

Brush Cleaner Motorized System

| Part Number | Belt Width in. | Belt Width mm. | Brush Diameter | Shaft | Weight lbs |

|---|---|---|---|---|---|

| M-ASG-RBC-24-M | 24 | 600 | 8" | 1" | 0 |

| M-ASG-RBC-30-M | 30 | 750 | 8" | 1" | 0 |

| M-ASG-RBC-36-M | 36 | 900 | 8" | 1" | 0 |

| M-ASG-RBC-42-M | 42 | 1050 | 8" | 1" | 0 |

| M-ASG-RBC-48-M | 48 | 1200 | 8" | 1.5" | 0 |

| M-ASG-RBC-54-M | 54 | 1350 | 8" | 1.5" | 0 |

| M-ASG-RBC-60-M | 60 | 1500 | 8" | 1.5" | 0 |