PROVIDES POWERFUL LOAD SUPPORT

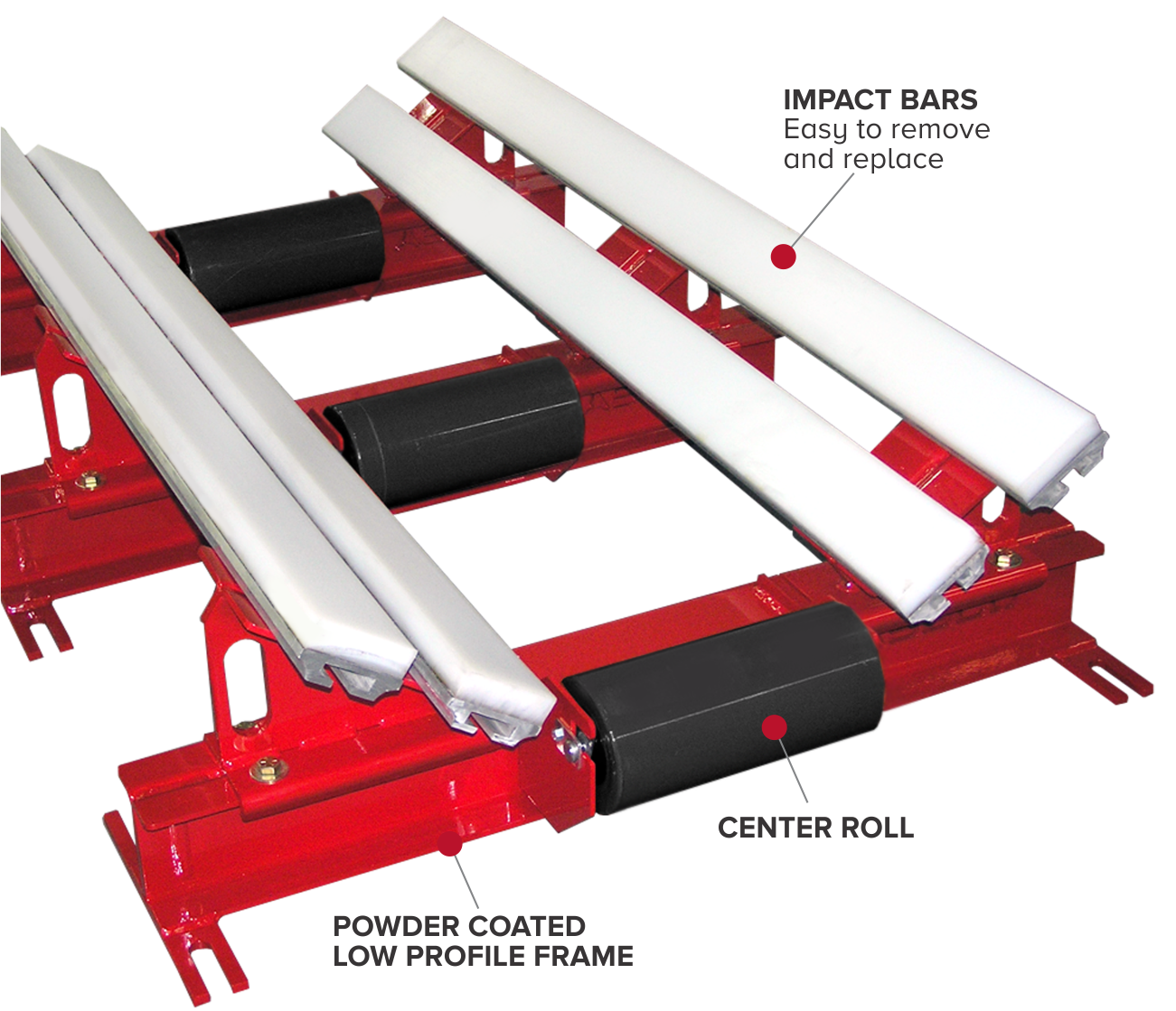

Design Features

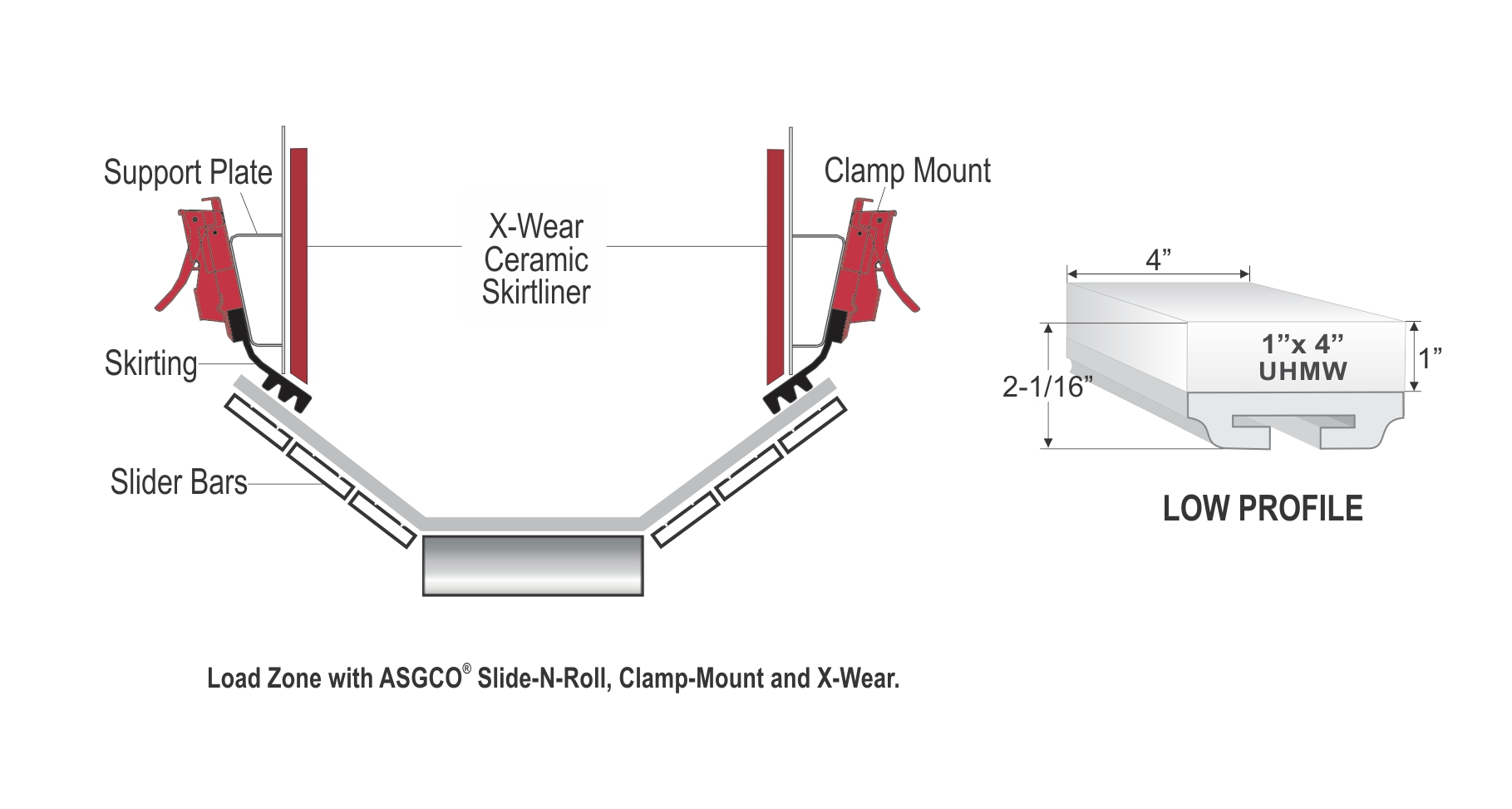

- Increase Belt Life – by eliminating the gaps, scalloping and pinch points between the belt and the skirt liners which can cut and gouge the belt, are eliminated.

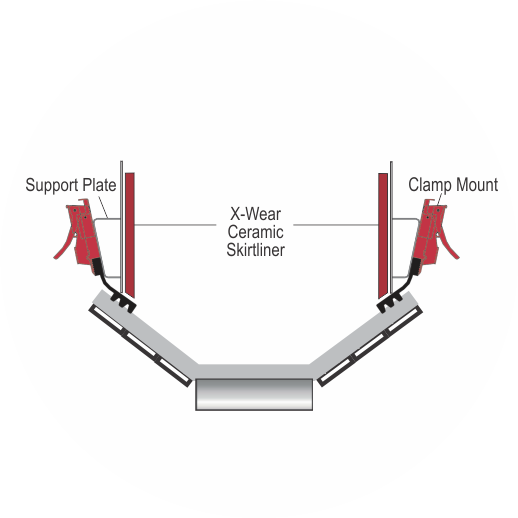

- Seals the Transfer Point – by supporting the belt edge on a flat surface that allows the skirting to work more effectively for an effective seal.

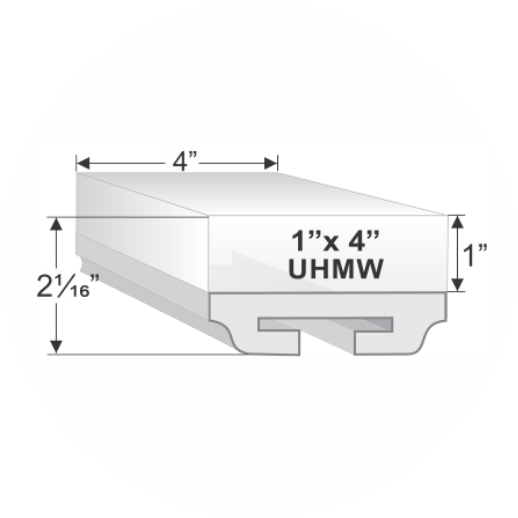

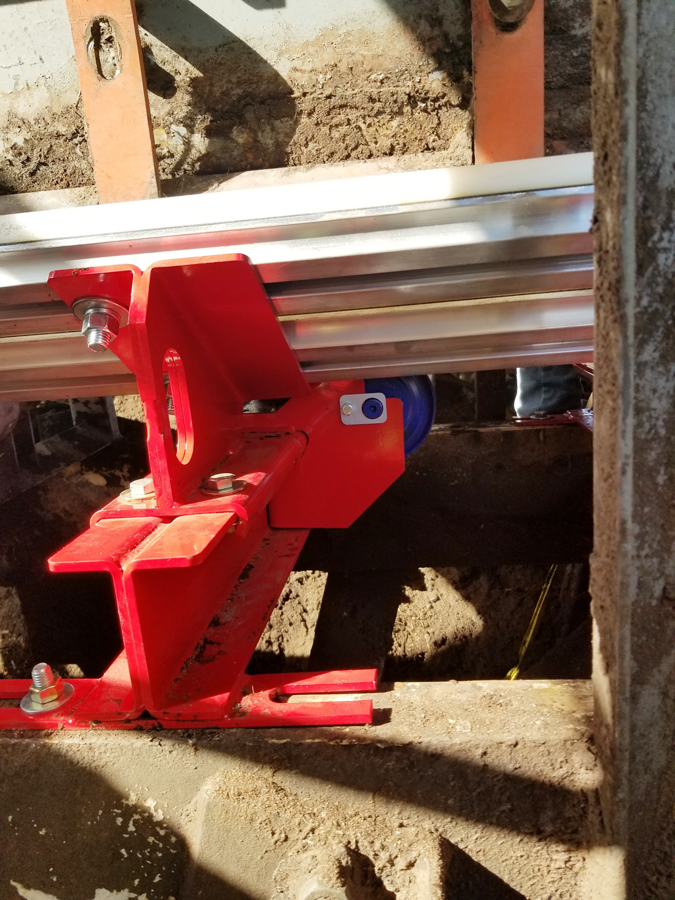

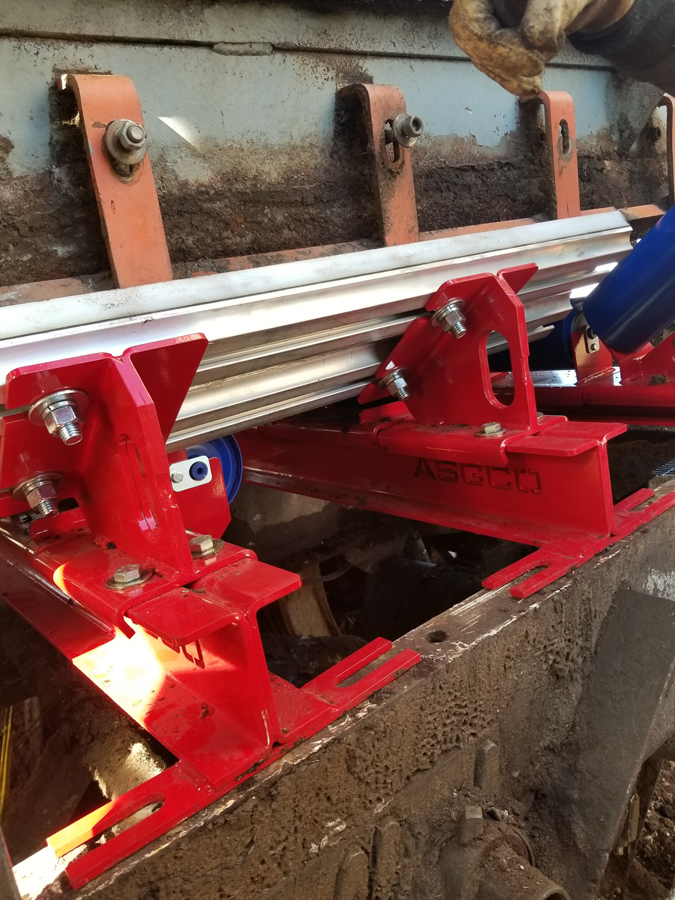

- Robust Designed – steel frames and 1” (25mm) thick UHWM slider bars provide excellent wear life.

- Engineered and Designed – beds can be made into

4′ (1200mm), 5′ (1500mm), 6’ (1800mm) or 10′ (3000mm) lengths.

- Any troughing angle.

- Number of frames will be determined by each application.

Product Specifications

Maximum Belt Speed – 800 fpm (4.0 m/sec) Applications – Aggregate, Sand & Gravel, Redi-Mix and Asphalt, Cement, Wood Processing, Recycling Replacement Parts – Center Idler Rolls, Low Profile Frame (1” thick, 4” wide) and S&R Low Profile Frame. Impact Bars – Length 2”, 4” or 5” Trough Angle – available in 20°, 35° and 45°Part Numbers

Slide-N-Roll™ – 4 Ft. Long Bed (No Center Bars) 2 Supports – 20,35,45

| Part Number | No.of Bars | Belt Width in. | Belt Width mm. | Weight Lbs |

|---|---|---|---|---|

| M-S&RLD-24-4-48-2-(XX) | 4 | 24 | 600 | 179 |

| M-S&RLD-30-4-48-2-(XX) | 4 | 30 | 750 | 205 |

| M-S&RLD-36-6-48-2-(XX) | 6 | 36 | 900 | 272 |

| M-S&RLD-42-6-48-2-(XX) | 6 | 42 | 1050 | 305 |

| M-S&RLD-48-6-48-2-(XX) | 6 | 48 | 1200 | 347 |

| M-S&RLD-54-8-48-2-(XX) | 8 | 54 | 1350 | 389 |

| M-S&RLD-60-8-48-2-(XX) | 8 | 60 | 1500 | 431 |

| M-S&RLD-72-10-48-2-(XX) | 10 | 72 | 1800 | 472 |

Part Numbers

Slide-N-Roll™ – 5 Ft. Long Bed (No Center Bars) 3 Supports – 20,35,45

| Part Number | No. of Bars | Belt Width in. | Belt Width mm. | Weight Lbs |

|---|---|---|---|---|

| M-S&RLD-24-4-60-3-(XX) | 4 | 24 | 600 | 252 |

| M-S&RLD-30-4-60-3-(XX) | 4 | 30 | 750 | 305 |

| M-S&RLD-36-6-60-3-(XX) | 6 | 36 | 900 | 381 |

| M-S&RLD-42-6-60-3-(XX) | 6 | 42 | 1050 | 436 |

| M-S&RLD-48-6-60-3-(XX) | 6 | 48 | 1200 | 490 |

| M-S&RLD-54-8-60-3-(XX) | 8 | 54 | 1350 | 805 |

| M-S&RLD-60-8-60-3-(XX) | 8 | 60 | 1500 | 1120 |

| M-S&RLD-72-10-60-3-(XX) | 10 | 72 | 1800 | 1352 |