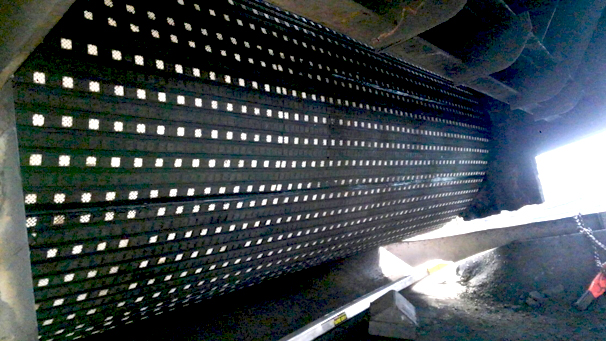

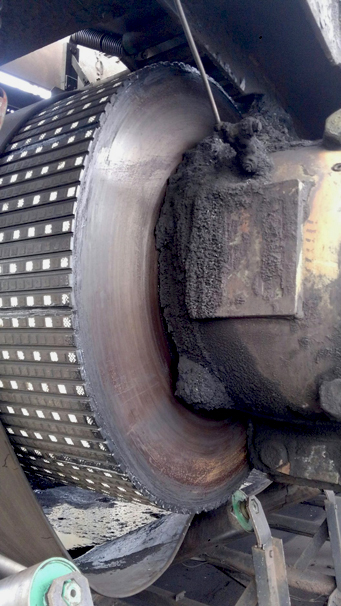

Challenge: Aggregate plant was experiencing severe mistracking in the center…

Read More >CORRECTS BELT SLIPPAGE AND PREMATURE WATER

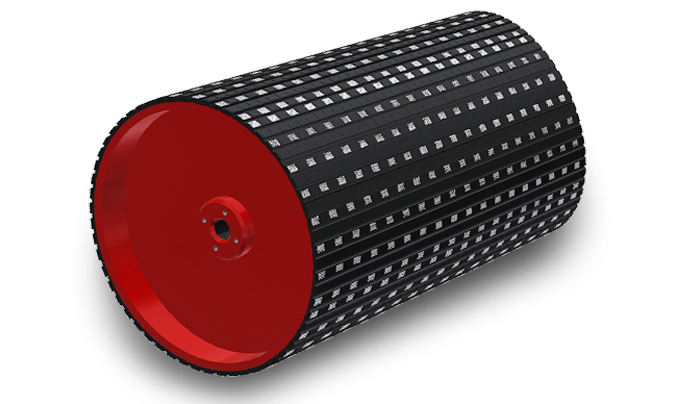

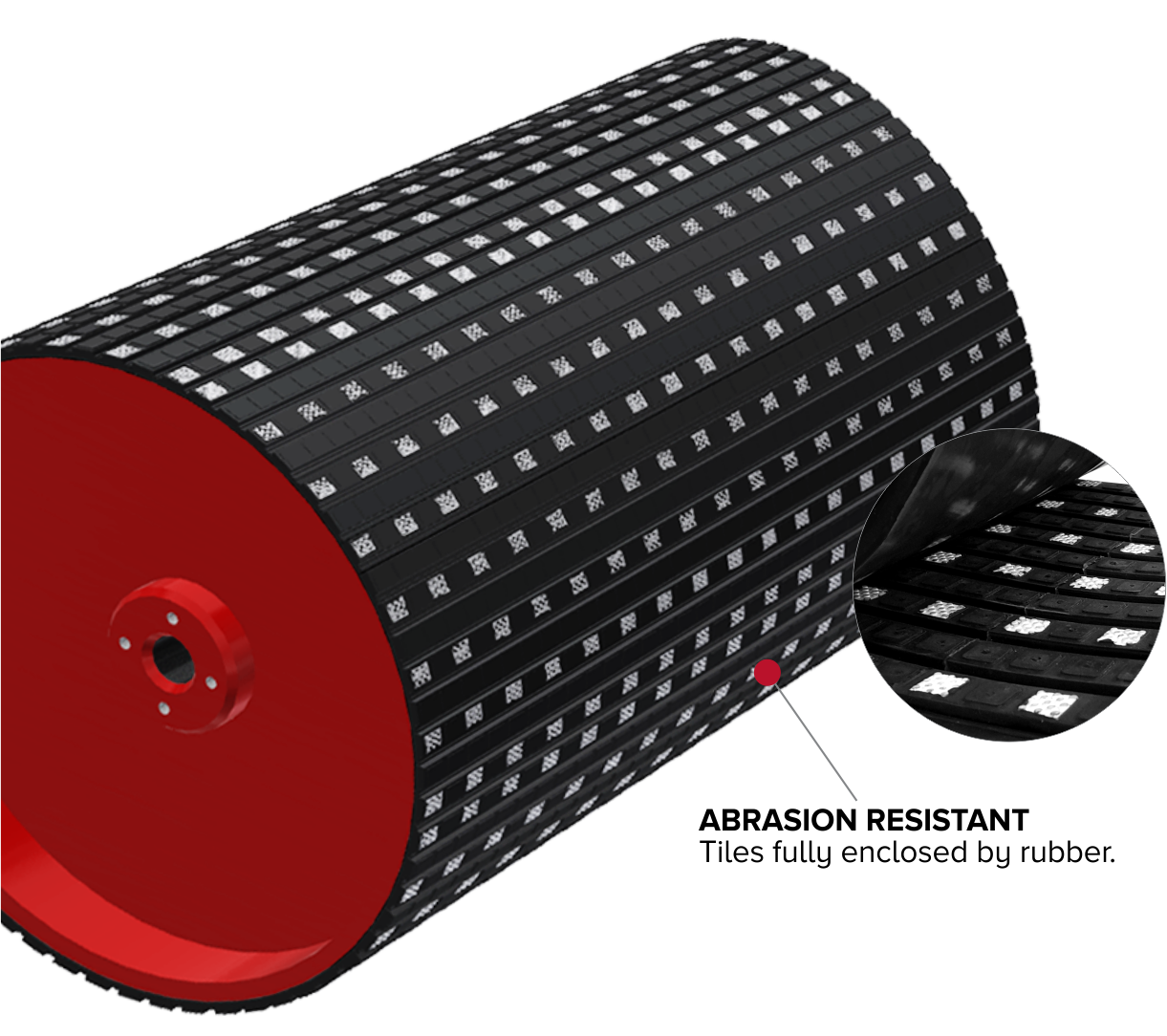

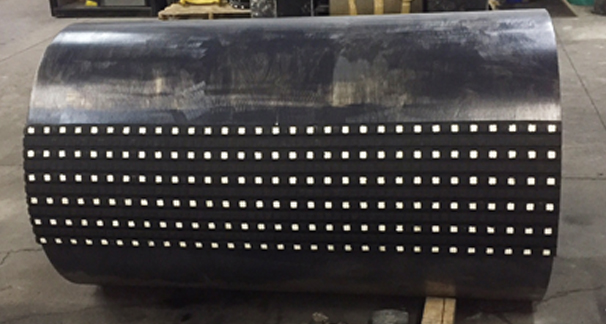

Design Features

- Newly Improved Ceramic Tile – provides robust performance in dry, wet, or muddy applications.

- High Grade – aluminum oxide ceramic

- Bonding Strength – that is superior to others, due to 3mm of our neoprene compound vulcanized into bottom-side of the lagging.

- Pre-Chemical Backing – for ease in installation

- Increase Productivity – by delivering increased traction between the conveyor belt and pulley, allowing for lower belt tension than with rubber lagging.

- Reduce Down Time – on non drive pulleys, where pulley change-out due to excessive wear is difficult.

- Rounded corners – allow for better adhesion between the rubber and the tile.

PRODUCT SPECIFICATIONS

Part Numbers

Semi-Ceramic Pulley Lagging

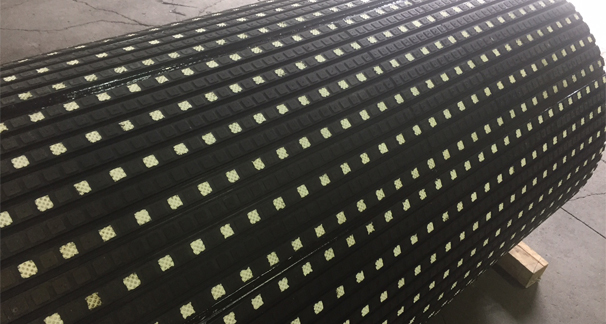

Abrasion Resistant tiles fully enclosed by rubber – Available in Rolls

| Part Number | Description | Weight lbs |

|---|---|---|

| ASG-15X32.81-SCRL | 15" (385mm) wide x 32.81' (10M) long | 120 |

Literature Downloads

Solutions Case Studies

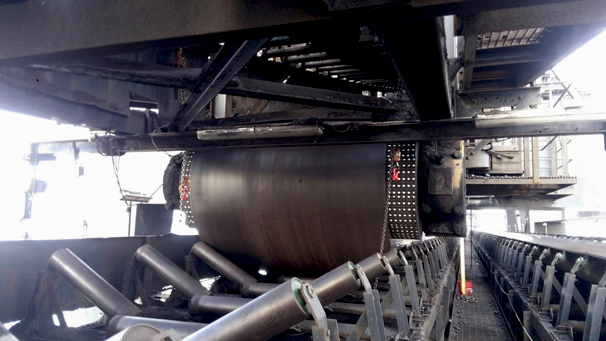

Objective: To eliminate belt slippage problems while minimizing belt wear….

Read More >