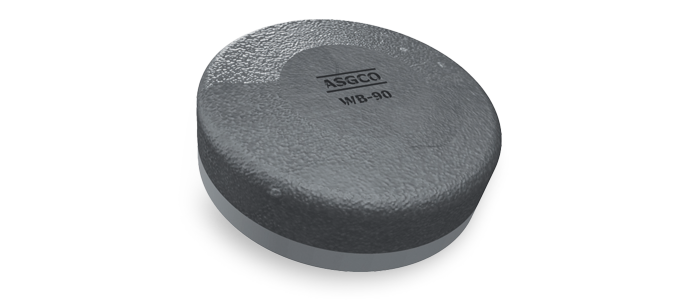

ARMORITE® CONVEYOR WEAR BUTTONS

Design Features

- White Iron: Modified AS2027 15/3 Cr Mo

- Vacuumed brazed and liquid nitrogen cooled to achieve a high strength joint

- Mild steel backing offers strength, machinability, and impact resistance

- Can be welded in place, through-bolted, stud bolted, drilled, tapped, keyed.

- Ease if fitment, very versatile

- Lower operating costs

- Longer Service when compared to conventional materials

- Increased production

- Improved product efficiency

- Increased equipment availability

PRODUCT SPECIFICATIONS

Applications – Chute Linings, Rock-Box Edges, Grizzly Caps/Screens, Transfer Points, Impact Plates, Distributor Plates, Arm/Hub Liners, Bin Liners, Hopper Wear Plates, Divder/Splitter Bars, General Wear Protection, Liner Panels Available Thickness – White Iron 3/4” – Base Plate 3/8” Available Diameter – 60mm up to 150mmPart Numbers

Armorite® Wear Button

Thickness White Iron 3/4″ – Thickness Base Plate 3/8″

| Part Number | Description | Diameter In. | Thickness in. | Weight lbs |

|---|---|---|---|---|

| ASG-AMR-WB-90 | Wear Button | 3-1/2 | 1-3/8 | 3 |