STUB IDLER DESIGNED FOR HEAVY LOADS

Design Features

- Designed to provide increased sidewall conveyor belt life.

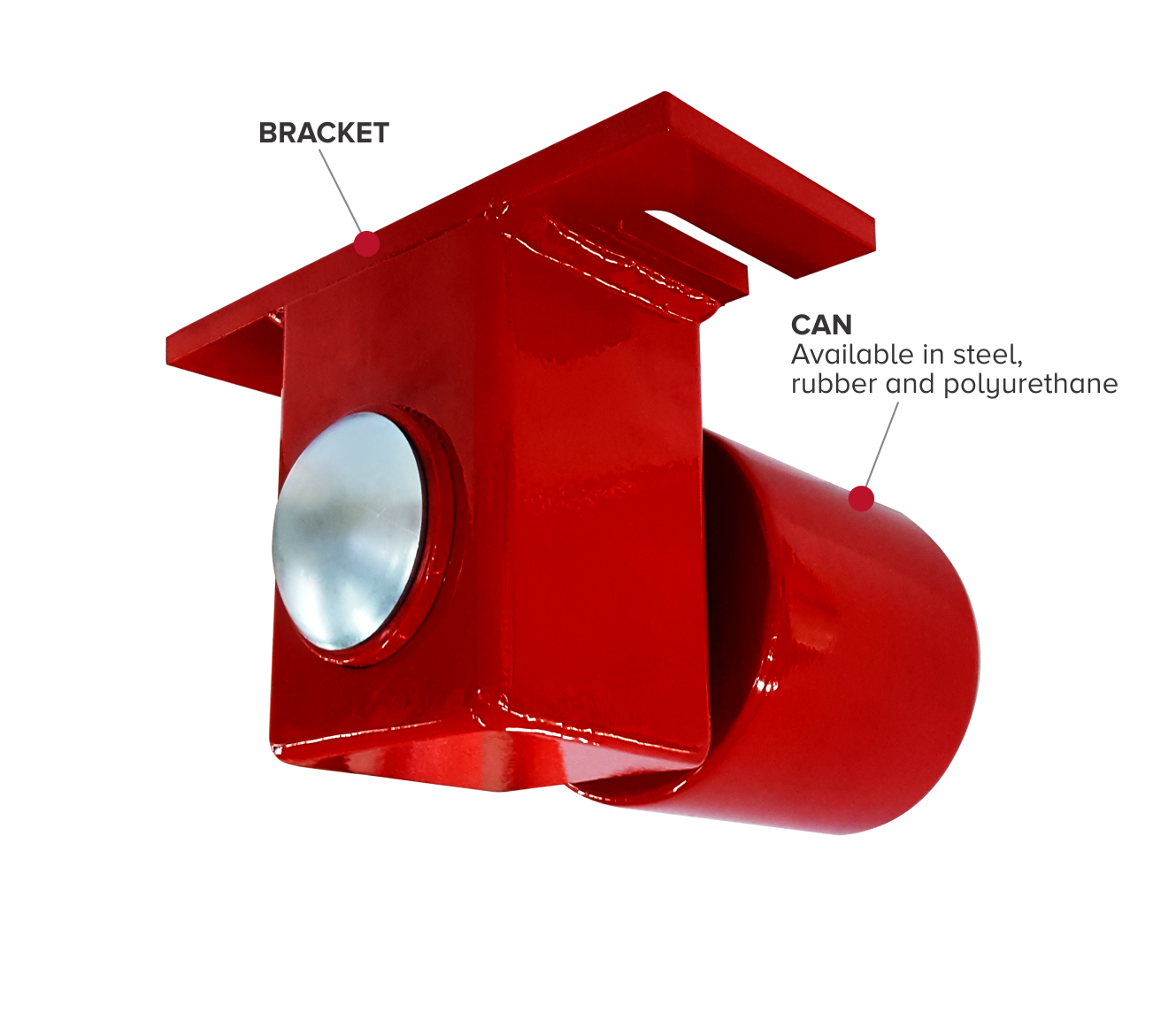

- Designed its stub idlers (patented) with the regreasable bearings located in a housing with a non-rotating grease fitting and the roller welded to the shaft.

- Incorporates the proper decline angle of 0°, 3° or 5° for the roller to match the belt manufacturer’s recommendation and offers the idlers in “drop” or “rise” designs to fit all conveyor frame/belt combinations.

- Rollers are available in steel, rubber covered or solid polyurethane.

- Designed for heavy load support and high belt speeds.

- Increased production capacity allows for quicker delivery on all custom sizes.

Part Numbers

This is a custom ASGCO® product, for more information contact us.