Challenge: The cleaners previously installed on the belt head were…

Read More >MECHANICAL SPLICES? NO PROBLEM.

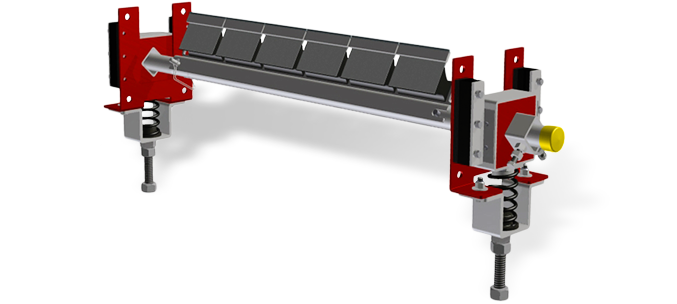

Design Features

- Longwearing Abrasion Resistant Blades – available with replaceable V-Tips for vulcanized conveyor belts or C-Tips or F-Tips for conveyor belts with mechanical fasteners. Also available with Urethane and AR™ 400 blades.

- Impact Absorbing Tension Cushions – each individual blade to the belt for a controlled and effective belt cleaning across the entire width of the belt.

- Compact Design – allows for an installation that requires less then 9” of clearance to be installed and maintained.

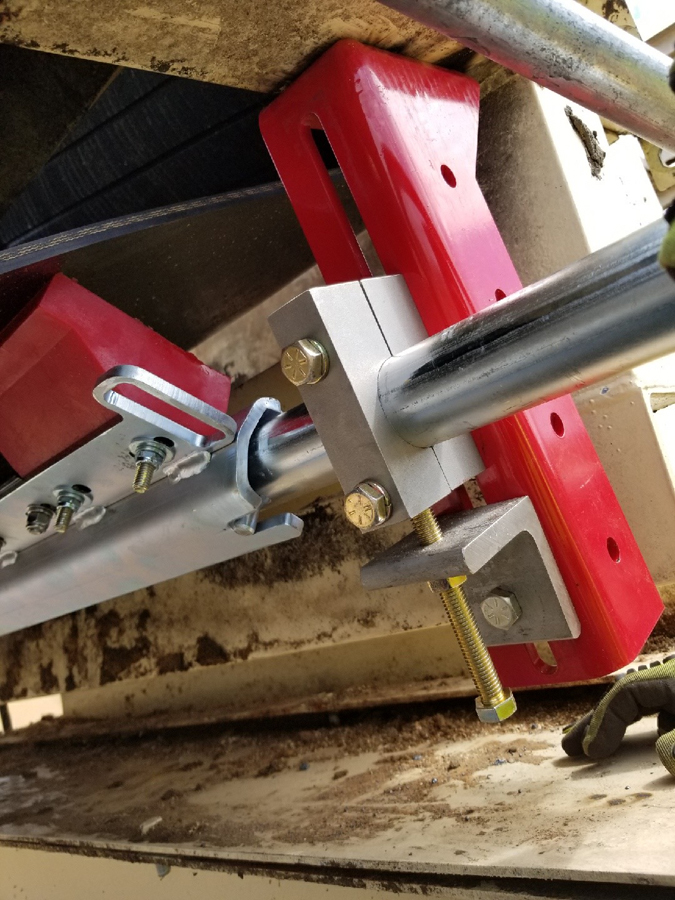

- Mechanical Splices? No Problem – The Razor-Back® can be installed on belts with mechanical splices, due to the laid-back wiping blade angle and impact- absorbing tensioning cushions, allowing the mechanical splices to pass without damaging the belt cleaner or the splice.

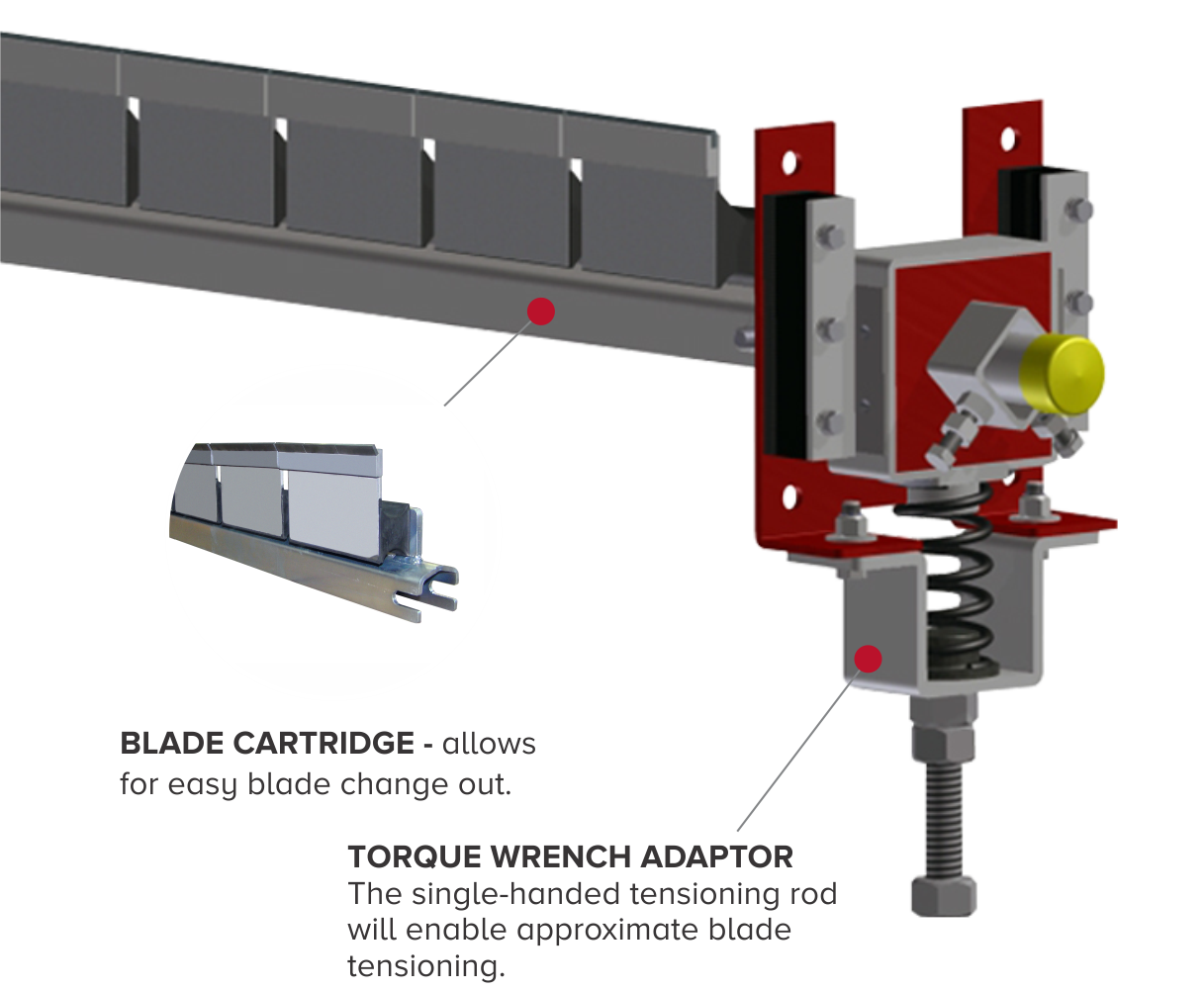

- Blade Cartridge – allows for easy change out of scraper blades from either side of the conveyor

- Available Tensioning Systems – Bolt-Up™, Duo-Spring™, or Spring-Shoc™

- Available Optional Spray-Bar – Spray nozzle sizes can be customized for any desired spray pattern and water pressure.

PRODUCT SPECIFICATIONS

- Maximum Belt Speed – 1000 fpm (5.0 m/sec)

- Application – Coal Fired Power Plants, Hard Rock Mining, Steel Mills, Iron Ore, Aggregate and Mineral (Phosphate, Potash, Salt) Mining.

Part Numbers

Razor-Back® with Spring-Shoc™ Tensioner System with F-Tips

F-Tips: Belt Speed: <1000 fpm <5m/sec / -20-400°F -28 to 204°C

| Part Number | Belt Width in. | Belt Width mm. | Weight lbs |

|---|---|---|---|

| M-RBAR-SYS-18-ST | 18 | 450 | 76 |

| M-RBAR-SYS-24-ST | 24 | 600 | 85 |

| M-RBAR-SYS-30-ST | 30 | 750 | 94 |

| M-RBAR-SYS-36-ST | 36 | 900 | 103 |

| M-RBAR-SYS-42-ST | 42 | 1070 | 112 |

| M-RBAR-SYS-48-ST | 48 | 1200 | 121 |

| M-RBAR-SYS-54-ST | 54 | 1350 | 130 |

| M-RBAR-SYS-60-ST | 60 | 1500 | 148 |

| M-RBAR-SYS-66-ST | 66 | 1600 | 148 |

| M-RBAR-SYS-72-ST | 72 | 1800 | 157 |

| M-RBAR-SYS-84-ST | 84 | 2100 | 175 |

Part Numbers

Razor-Back® with Spring-Shoc™ Tensioner System with C-Tips

C-Tips: Belt Speed: <1000 fpm <5m/sec / -20-400°F -28 to 204°C

| Part Number | Belt Width in. | Belt Width mm. | Weight lbs |

|---|---|---|---|

| M-RBC-SYS-18-ST | 18 | 450 | 75 |

| M-RBC-SYS-24-ST | 24 | 600 | 85 |

| M-RBC-SYS-30-ST | 30 | 750 | 94 |

| M-RBC-SYS-36-ST | 36 | 900 | 103 |

| M-RBC-SYS-42-ST | 42 | 1050 | 112 |

| M-RBC-SYS-48-ST | 48 | 1200 | 121 |

| M-RBC-SYS-54-ST | 54 | 1350 | 130 |

| M-RBC-SYS-60-ST | 60 | 1350 | 130 |

| M-RBC-SYS-66-ST | 66 | 1600 | 148 |

| M-RBC-SYS-72-ST | 72 | 1800 | 157 |

| M-RBC-SYS-84-ST | 84 | 2100 | 175 |

Part Numbers

Razor-Back® with Spring-Shoc™ Tensioner System with V-Tips

V-Tips: Belt Speed: <1000 fpm <5m/sec / -20-400°F -28 to 204°C

| Part Number | Belt Width in. | Belt Width mm. | Weight lbs |

|---|---|---|---|

| M-RBTC-SYS-18-ST | 18 | 450 | 76 |

| M-RBTC-SYS-24-ST | 24 | 600 | 85 |

| M-RBTC-SYS-30-ST | 30 | 750 | 94 |

| M-RBTC-SYS-36-ST | 36 | 900 | 103 |

| M-RBTC-SYS-42-ST | 42 | 1070 | 112 |

| M-RBTC-SYS-48-ST | 48 | 1200 | 121 |

| M-RBTC-SYS-54-ST | 54 | 1350 | 130 |

| M-RBTC-SYS-60-ST | 60 | 1500 | 139 |

| M-RBTC-SYS-66-ST | 66 | 1800 | 148 |

| M-RBTC-SYS-72-ST | 72 | 1800 | 157 |

| M-RBTC-SYS-84-ST | 84 | 2100 | 175 |

Literature Downloads

Solutions Case Studies

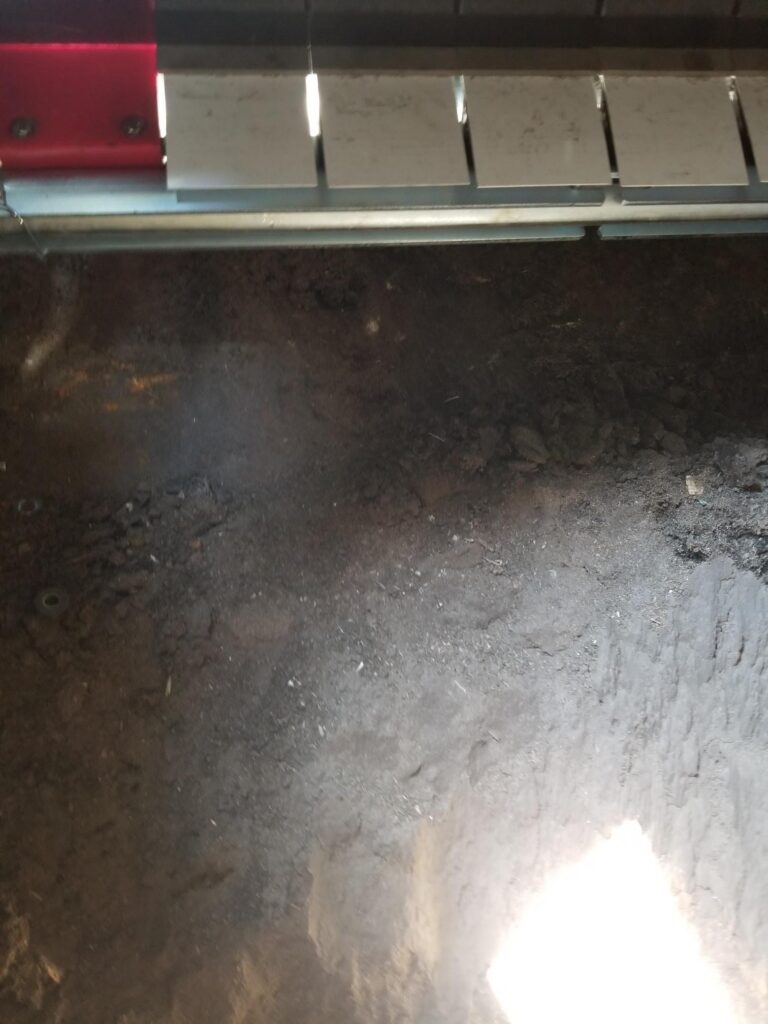

Objective: To remove the sticky carry-back from the conveyor belt….

Read More >

ASGCO has successfully reduced the carry back to levels that…

Read More >

Objective: Remove carry-back to eliminate housekeeping and clean-up requirements while improving…

Read More >