ASGCO®’s Clamp-Mount™ System With Dura-Seal™ Skirtboard Sealing Compound Solves Transfer…

Read More >ACCOMMODATES EXCESSIVE FORCE ON CONVEYOR BELTS & HEAVY LOADS

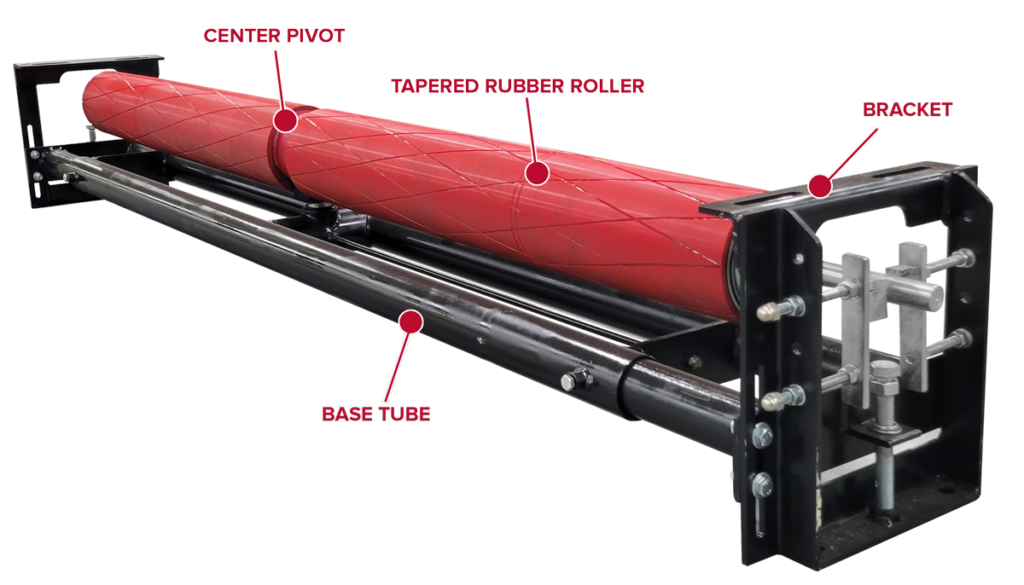

Design Features

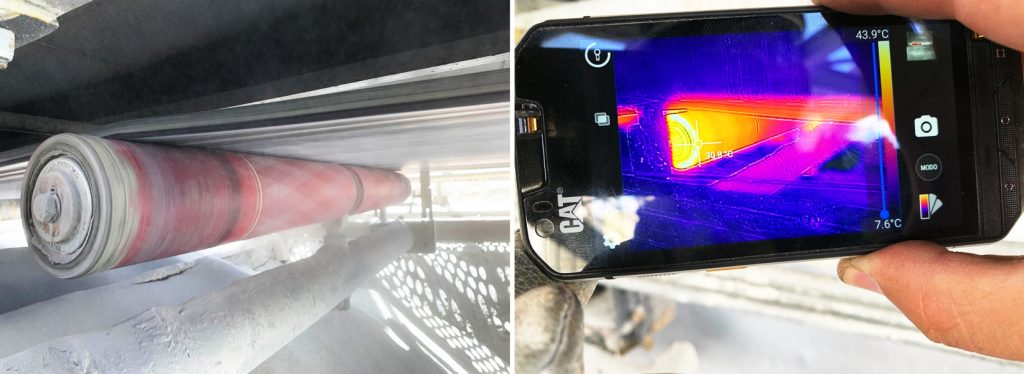

- Designed for High Speed/PIW Conveyors – to operate and last is severe conditions, wet and dry, and aggressive mining conditions. – Conveyor belt speeds that exceed 800 fpm and/or greater than 1500 PIW.

- Heavy Duty Rolls – 3/4″ polyurethane lagged, tapered rollers are mounted onto the pivot mechanism, which can be individually replaced as wear occurs.

- Enhanced Sealing/Bearing System – needle thrust and tapered roller bearings and enhanced sealing system for the most aggressive mining conditions.

- Total Satisfaction Guarantee (TSG) – to solve your conveyor belt training problems and make your overall conveyor system run more efficiently.

MOST RELIABLE AND RE-ACTIVE BELT TRACKING IDLERS!

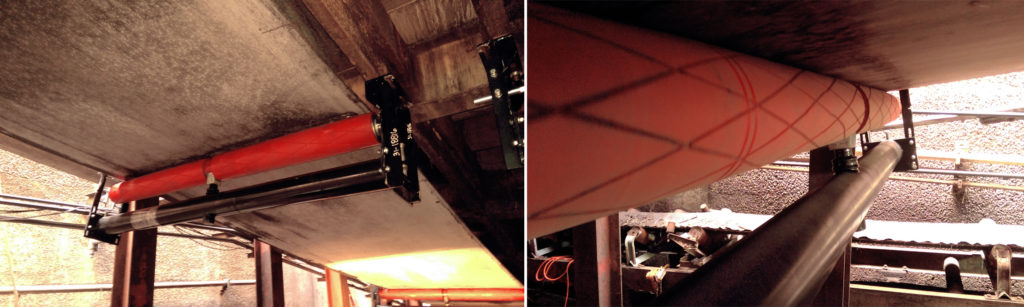

The Tru-Trainer® series of conveyor belt tracking idlers are a patented design that offers the most reliable and re-active belt tracking idlers available today.

- The mine duty idle was developed to accommodate the excessive forces encountered with wide belts and heavy loads

- Belt Width 48” – 96”

- Idlers can be mounted on the topside or clean side of the conveyor belt.

PRODUCT SPECIFICATIONS

Application – Aggregate, Cement, Mineral (Phosphate, Potash, Salt) Mining, Underground Mining, Coal Fired Power Plant, Hard Rock Mining, Metals (Copper/Gold) Mining, Steel Mill, Iron Ore, Bulk Shipping TerminalsPart Numbers

Tru-Trainer® Dual Return Urethane Idler

| Part Number | Belt Width in. | Belt Width mm. | Weight lbs |

|---|---|---|---|

| ASG-TTDR-120-UE-1 | 48 | 1200 | 295 |

| ASG-TTDR-135-UE-1 | 54 | 1350 | 304 |

| ASG-TTDR-150-UE-1 | 60 | 1500 | 336 |

| ASG-TTDR-165-UE-1 | 66 | 1650 | 354 |

| ASG-TTDR-180-UE-1 | 72 | 1800 | 358 |

| ASG-TTDR-210-UE-1 | 84 | 2100 | 418 |

Solutions Case Studies

Dual Return Urethane Tru-Trainer (ASGCO Featured in the June Issue…

Read More >