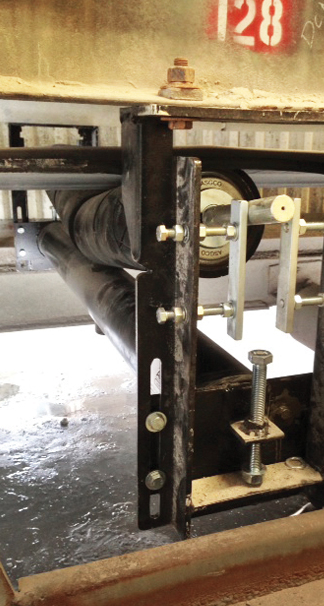

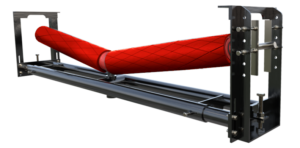

ACCOMODATES EXCESSIVE FORCE WITH V-RETURN IDLER CONVEYORS

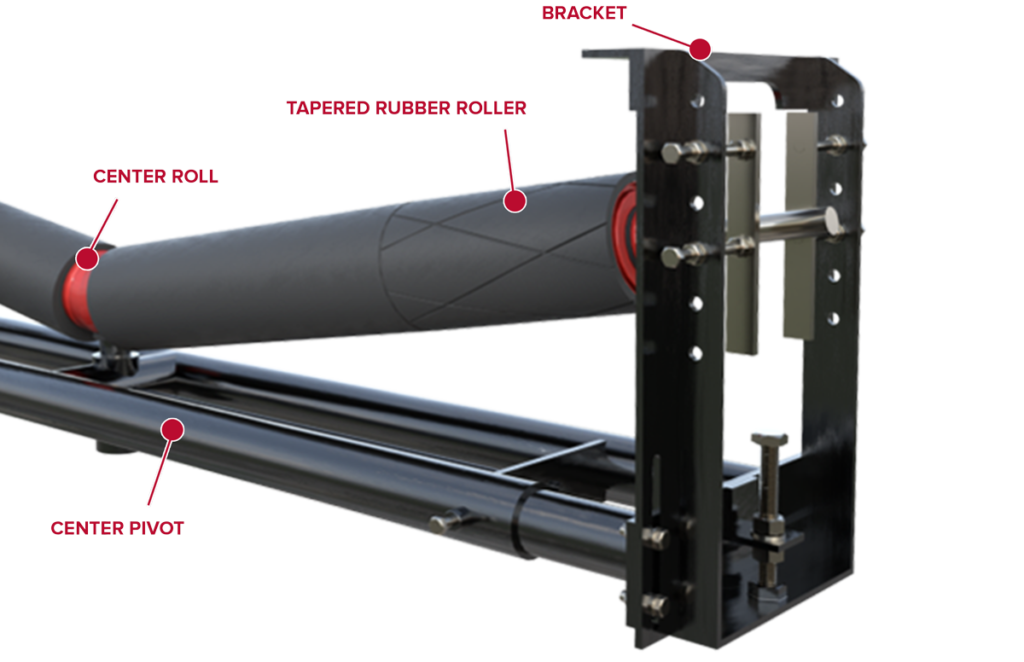

Design Features

- Two Separate Tapered Rolls – are mounted into the pivot mechanism and can be individually replaced as wear occurs

- Designed for High Speed/PIW Conveyors – to operate and last in severe conditions, wet and dry, and aggressive mining conditions. Conveyor belt speeds that exceed 800 fpm and/or greater than 1500 PIW.

- Accommodates Excessive Force – encountered with wide belts and heavy loads.

- Enhanced Sealing/Bearing System – needle thrust and tapered roller bearings and enhanced sealing system for the most aggressive mining conditions.

- Individual Rollers for Easy Replacement – separate tapered rolls are mounted onto the pivot mechanism, which can be individually replaced as wear occurs.

PRODUCT SPECIFICATIONS

Application – Aggregate, Cement, Mineral (Phosphate, Potash, Salt) Mining, Underground Mining, Coal Fired Power Plant, Hard Rock Mining, Metals (Copper/Gold) Mining, Steel Mill, Iron Ore, Bulk Shipping TerminalsPart Numbers

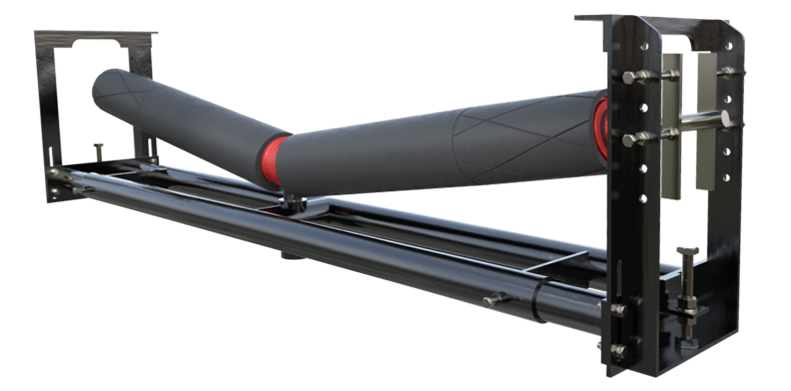

Tru-Trainer® Dual V-Return

| Part Number | Belt Width in. | Belt Width mm. | Weight lbs |

|---|---|---|---|

| ASG-TTVR-105-1 | 42 | 1050 | 300 |

| ASG-TTVR-120-1 | 48 | 1200 | 304 |

| ASG-TTVR-135-1 | 54 | 1350 | 309 |

| ASG-TTVR-150-1 | 60 | 1500 | 348 |

| ASG-TTVR-165-1 | 66 | 1650 | 368 |

| ASG-TTVR-180-1 | 72 | 1800 | 419 |

| ASG-TTVR-210-1 | 84 | 2100 | 521 |

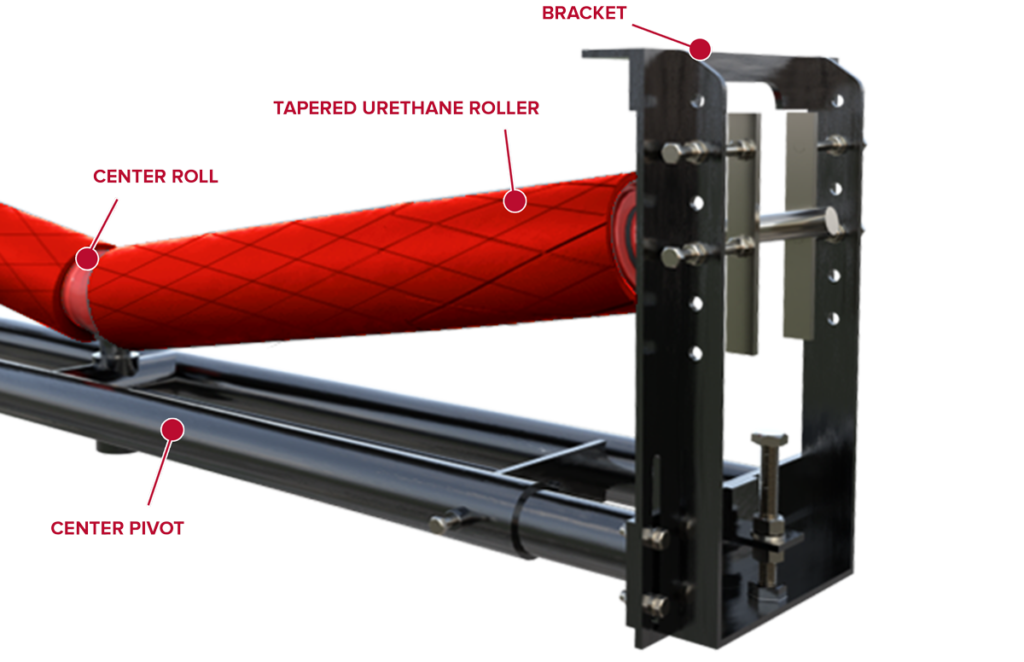

Part Numbers

Tru-Trainer® Dual V-Return Urethane Idler

| Part Number | Belt Width in. | Belt Width mm. | Weight lbs |

|---|---|---|---|

| ASG-TTVR-105-UE-1 | 42 | 1050 | 300 |

| ASG-TTVR-120-UE-1 | 48 | 1200 | 304 |

| ASG-TTVR-135-UE-1 | 54 | 1350 | 309 |

| ASG-TTVR-150-UE-1 | 60 | 1500 | 348 |

| ASG-TTVR-165-UE-1 | 66 | 1650 | 368 |

| ASG-TTVR-180-UE-1 | 72 | 1800 | 419 |

| ASG-TTVR-210-UE-1 | 84 | 2100 | 521 |